Slow-release pesticide granule and preparation method thereof

A technology of slow-release pesticides and granules, applied in botany equipment and methods, biocides, fungicides, etc., can solve the problems of unsafety, poor slow-release effect, etc., and achieve a significant effect of slow-release pesticides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Preparation of pyraclostrobin sustained-release granules.

[0060] pyraclostrobin technical (content 95%), Shenyang Kechuang Chemicals Co., Ltd.

[0061] 1. Take 1000g of fly ash, Na 2 CO 3 250g was mixed evenly, placed in a muffle furnace, first kept at 500°C for half an hour, and then heated to 800°C for calcination at a constant temperature for 2h. After drying, place in 1.5 mol / L NaOH and mix, react at 70°C for 10 hours, filter, and dry to obtain alkali-modified fly ash for future use.

[0062] 2. Take 400g of dry alkali-modified fly ash, 250g of straw, and 150g of biochar, mix them and grind them through a 70-mesh sieve to obtain a carrier.

[0063] 3. Fully mix pyraclostrobin with the fly ash, straw and biochar obtained in the previous step, and then dry it at 60°C for later use.

[0064] 4. Add 200g of starch to 400g of water, and gelatinize at 80°C for 1 hour.

[0065] 5. Spray the gelatinized starch solution on the mixture obtained in step 3 on the granul...

Embodiment 2

[0068] Preparation of pyraclostrobin sustained-release granules.

[0069] Pyraclostrobin (content 98%), Jiangsu Youjia Plant Protection Co., Ltd.

[0070] 1. Take 500g of dry alkali-modified fly ash, 200g of straw, and 200g of biochar, mix them and grind them through a 70-mesh sieve to obtain a carrier.

[0071] 2. After fully mixing the pyraclostrobin technical substance with the fly ash, straw and biochar obtained in the previous step, dry it at 60°C for later use.

[0072] 3. Add 80g of starch to 160g of water and gelatinize at 80°C for 1 hour.

[0073] 4. Spray the gelatinized starch solution on the mixture obtained in step 2 on the granulator to make a spherical core layer of 1-10mm, and dry it at 60°C for later use.

[0074] 5. Continue to spray the gelatinized starch solution on the dried core layer on the granulator, add 160g of straw to make a wrapping layer, the thickness of the wrapping layer is 0.2-2mm, and dry at 60°C to obtain.

experiment example 1

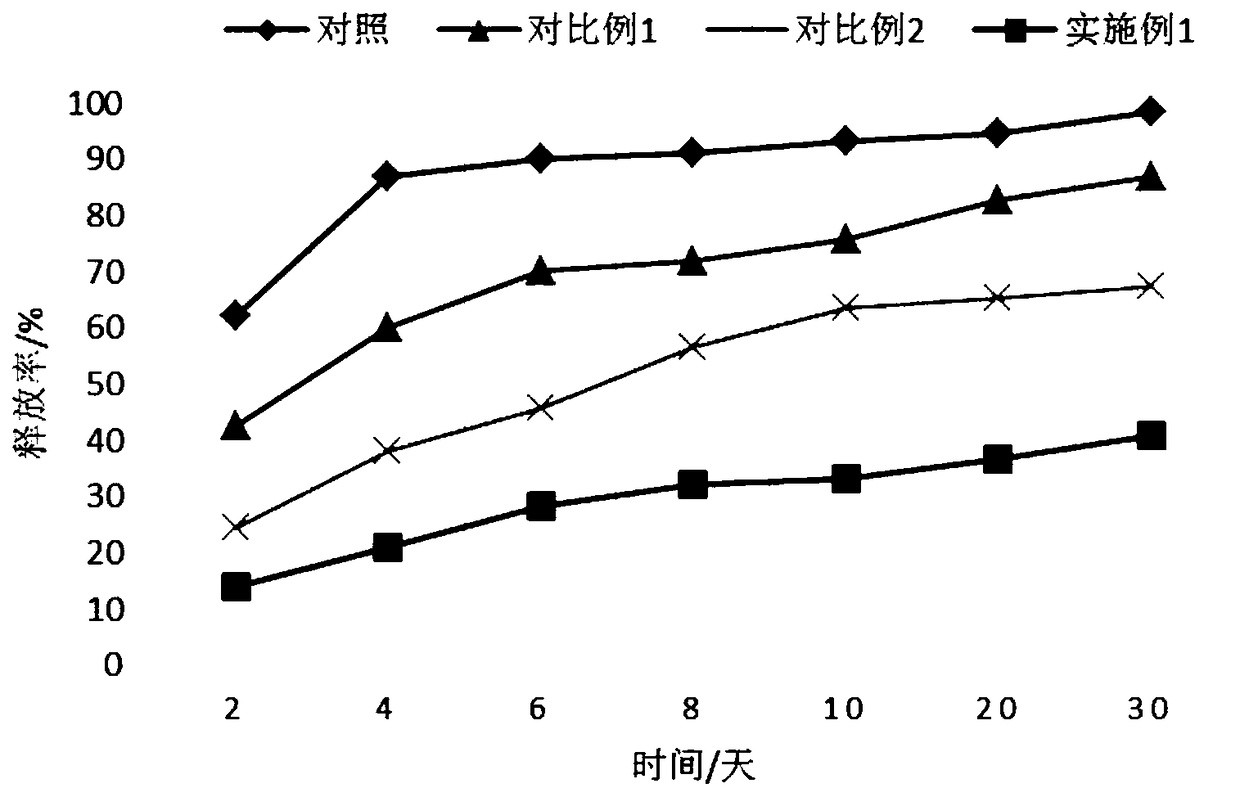

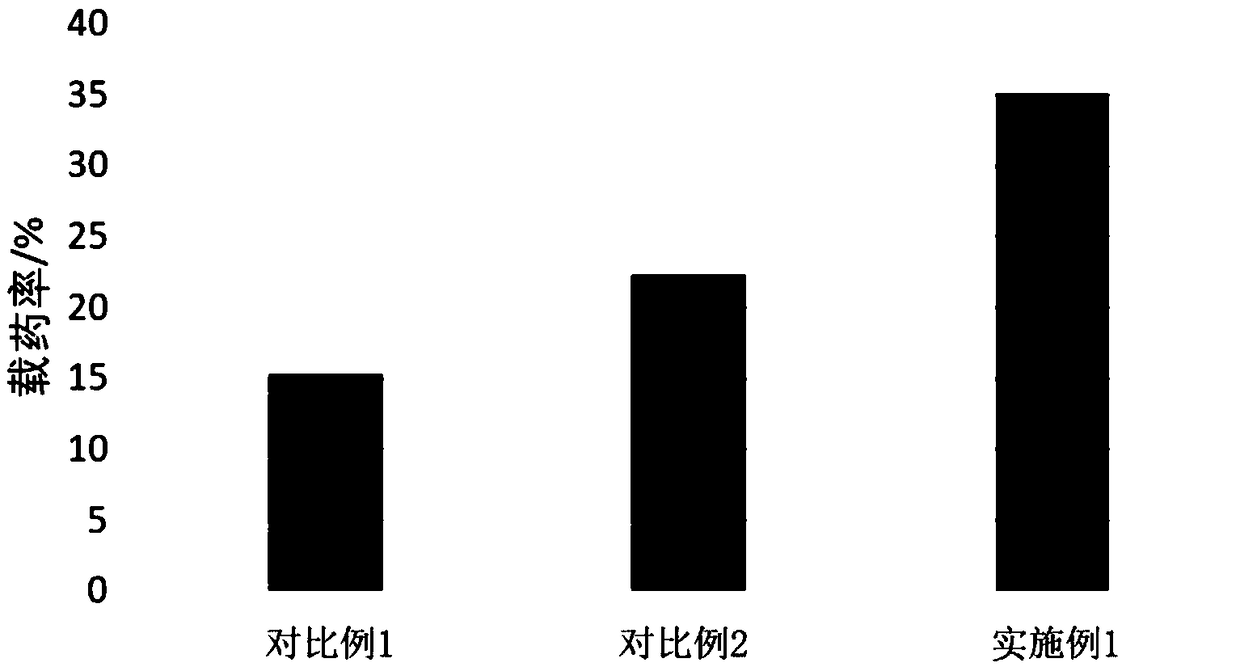

[0075] Experimental Example 1: Research on the slow-release effect of slow-release pesticide granules.

[0076] The setting of comparative example: set on the basis of embodiment 1, concrete method is as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com