Kanggongyan tablet and its preparation process

A preparation process and anti-uterine inflammation technology, which is applied in the field of medicine, can solve the problems that the preparation process needs to be improved, the tablet stability of anti-uterine inflammation tablets is not ideal, and the degree of color change is serious, and the time to achieve drug absorption is shortened, Better tablet appearance and better product stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

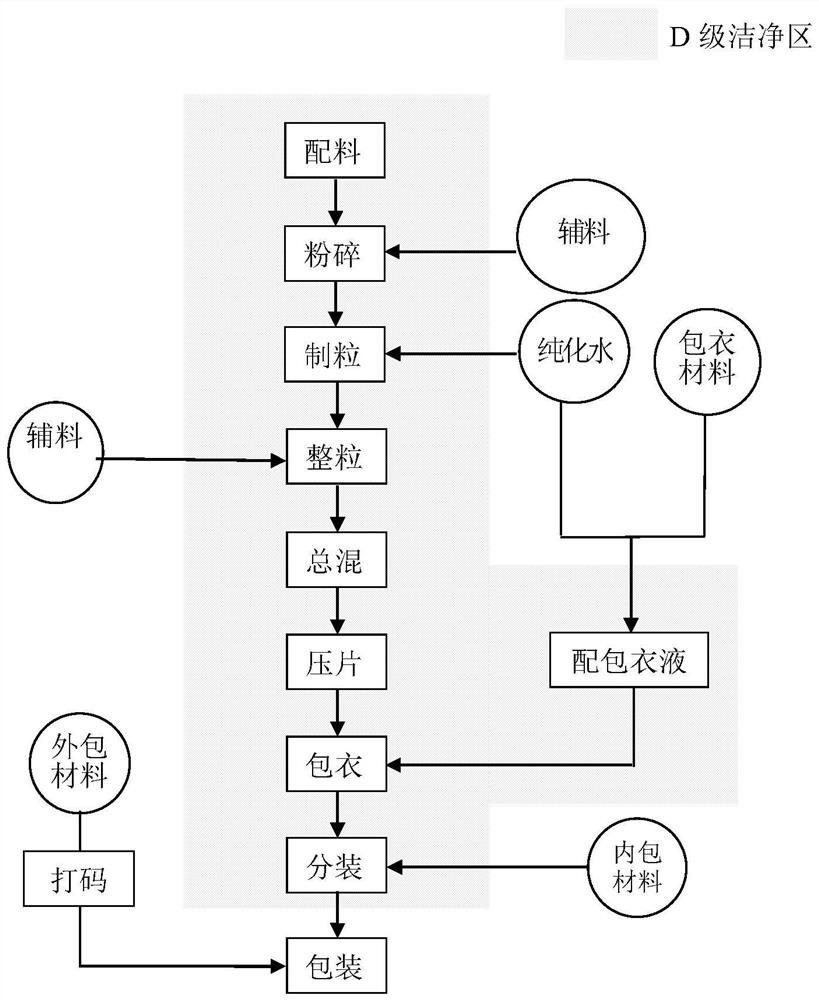

[0049] The preparation of the Kanggongyan Tablet of the present invention needs to be completed in a clean area of grade D or above, the temperature is kept at 18°C-26°C, and the relative humidity is controlled between 45%-65%. The number of air changes in the D-level clean area should be ≥15 times / h, the sedimentation bacteria should be ≤100cfu / 4 hours, the number of suspended particles under static conditions should not exceed 3520000 per cubic meter, and the particle size should not exceed 5.0um per cubic meter 29000.

[0050] The raw materials used in the examples of the present invention are common commercially available products.

Embodiment 1

[0051] Embodiment 1 A kind of prescription of Kanggongyan Tablet and its preparation method

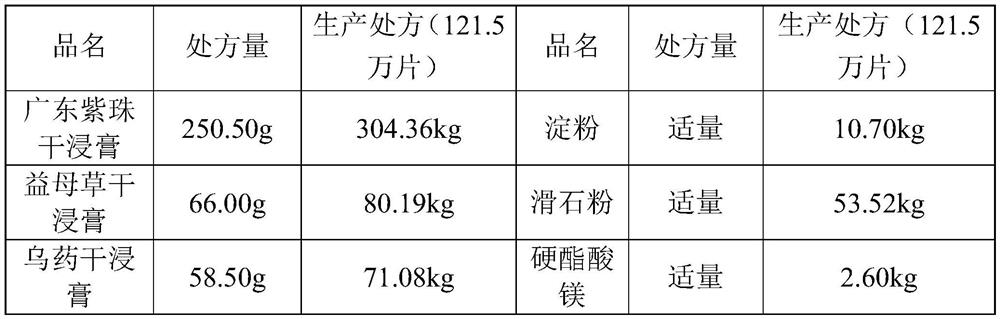

[0052] 1. Prescription

[0053] Prescription of anti-uterine tablets

[0054]

[0055] 2. Preparation process of Kanggongyan Tablets

[0056] A kind of preparation technology of Kanggongyan tablet comprises the following steps:

[0057] 1. Ingredients:

[0058] According to the production prescription, accurately weigh a batch of Guangdong Zizhu dry extract 304.36kg, Wuyao dry extract 71.08kg, Motherwort dry extract 80.19kg, starch 10.7kg, talc powder 53.52kg, put them in a clean stainless steel bucket, wait use.

[0059] 2. Crushing:

[0060] Mix and pulverize the Guangdong Zizhu dry extract, Wuyao dry extract, Leonurus dry extract, starch, and talcum powder handed over from the previous process into a fine powder, pass through a 100-mesh sieve, put it in a clean stainless steel bucket, and transfer it to the granulation process.

[0061] 3. Granulation:

[0062] The fine p...

Embodiment 2

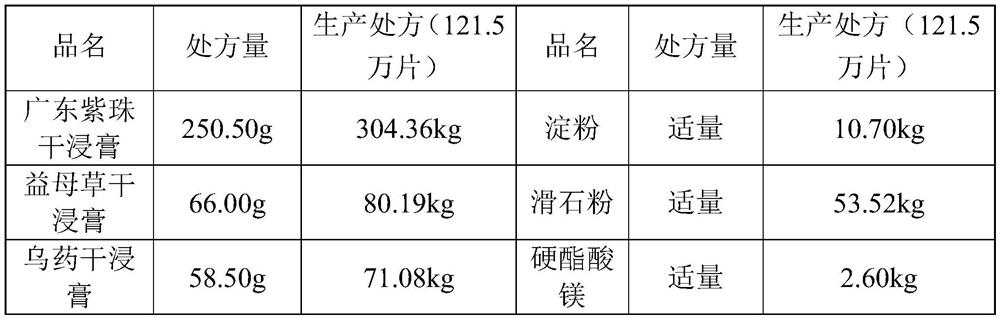

[0069] Embodiment 2 A kind of prescription and preparation technology of Kanggongyan tablet

[0070] 1. Prescription

[0071] 1. Prescription of Kanggongyan Tablets

[0072]

[0073] 2. Prescription of film coating solution

[0074] product name 1.215 million tablets consumption Pharmaceutical film coating premixed excipients (stomach-soluble type) 2.0%~3.0% talcum powder 6~10kg purified water 70~90kg

[0075] 2. Preparation process

[0076] The preparation process of embodiment 2 is basically the same as that of embodiment 1, the difference is that, with reference to figure 1 The preparation process flow chart of embodiment 2, on the basis of steps 1 to 6 of embodiment 1, also increases the steps of film coating and packaging, specifically:

[0077] Steps 1-6: the same as steps 1-6 of the embodiment.

[0078] 7. Film coating

[0079] Receive qualified substrates, each batch is divided into four pots for film coating, each pot is ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com