Cobalt catalyst for preparation of single-walled carbon nanotubes and preparation method and application of cobalt catalyst

A technology of single-walled carbon nanotubes and cobalt catalysts, applied in the direction of single-walled carbon nanotubes, carbon nanotubes, chemical instruments and methods, etc., can solve the problem of single-walled carbon nanotubes with large diameter, complex chirality, and narrow chirality distribution etc. to achieve the effects of short reaction time, easy access to raw materials, and simple synthesis methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

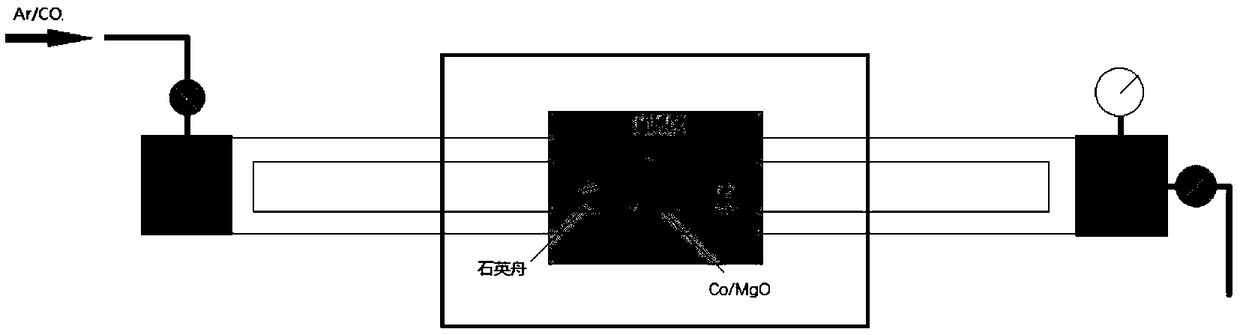

[0039] In a typical embodiment of the present invention, a kind of preparation method of cobalt catalyst is provided, and described method comprises:

[0040] S1. Magnesium oxide and cobalt nitrate are placed in water, stirred and dried, and then made into powder;

[0041] S2. Calcining the powder described in step S1 at a high temperature to obtain a cobalt catalyst.

[0042] In yet another specific embodiment of the present invention, in the step S1,

[0043] The mass ratio of magnesium oxide to cobalt nitrate is 1 to 3:4 (the preferred mass ratio is 1.4:4),

[0044] In yet another specific embodiment of the present invention, the preparation method of the magnesium oxide is: calcining basic magnesium carbonate to obtain MgO, the calcining conditions are: the calcining temperature is 350-450°C (preferably 400°C), and the calcining time is 0.5~1.5h (preferably 1h), the magnesium oxide that adopts above-mentioned method to prepare is high in purity, is convenient to use as t...

Embodiment 1

[0058] The preparation of embodiment 1 cobalt catalyst

[0059] (1) Calcining basic magnesium carbonate at 400° C. for one hour in a muffle furnace to obtain MgO.

[0060] (2) Take 1.4g of cobalt nitrate and 4g of magnesium oxide, dissolve in 15ml of distilled water and stir evenly, put the above solution in an oven, dry it at 100°C, and grind it into powder in a mortar.

[0061] (3) Put the above powder in a muffle furnace and calcinate at 450° C. for 9 hours.

Embodiment 2

[0062] The preparation of embodiment 2 cobalt catalysts

[0063] (1) Calcining basic magnesium carbonate at 400° C. for one hour in a muffle furnace to obtain MgO.

[0064] (2) Take 1.4g of cobalt nitrate and 4g of magnesium oxide, dissolve in 15ml of distilled water and stir evenly, put the above solution in an oven, dry it at 100°C, and grind it into powder in a mortar.

[0065] (3) Put the above powder in a muffle furnace and calcinate at 400° C. for 10 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com