Preparation method of Ru/C nano-assembly

A nano-assembly, solid matter technology, applied in chemical instruments and methods, electrolytic components, chemical/physical processes, etc., can solve the problems of low catalytic efficiency, low reserves and high cost of electrochemical reactions, and achieve excellent catalytic stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

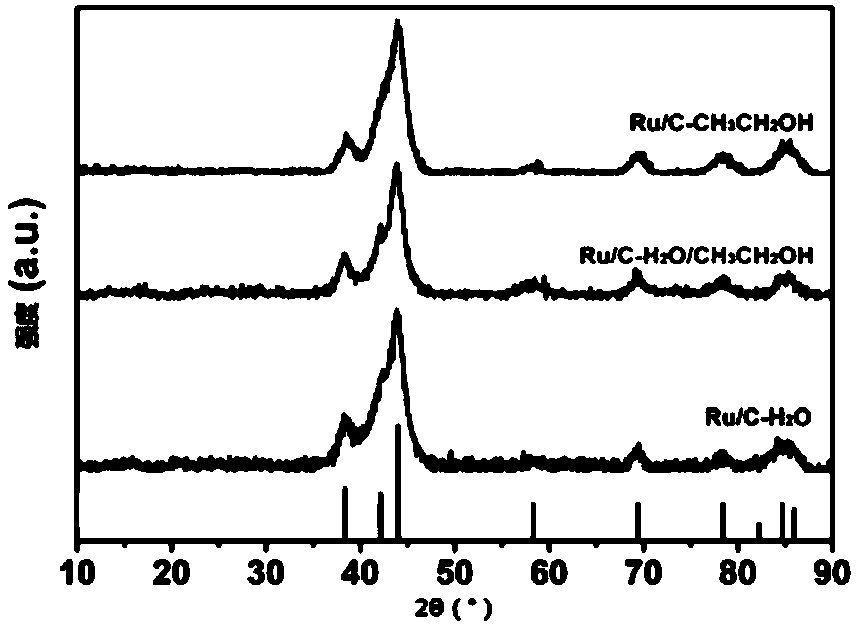

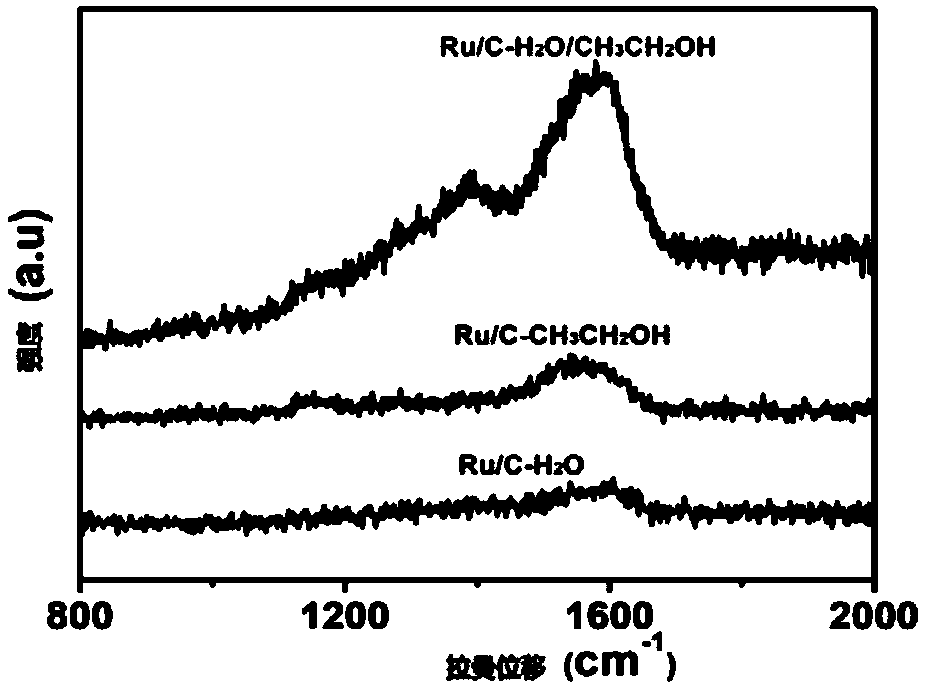

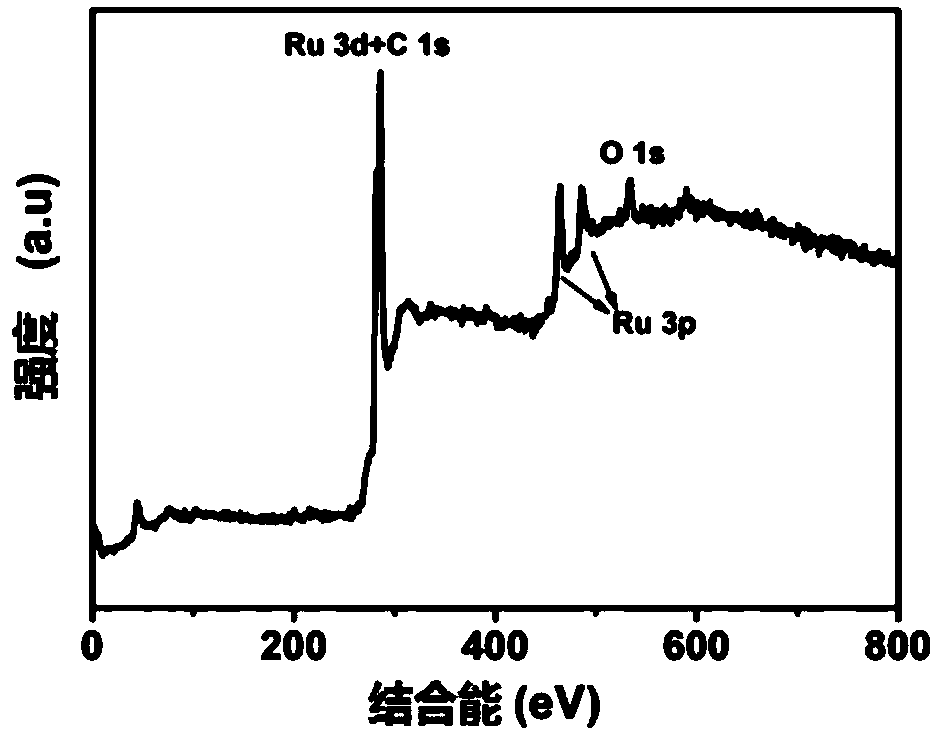

[0070] Specific embodiment one: the preparation method of a kind of Ru / C nano assembly of this embodiment, carry out according to the following steps:

[0071] 1. RuCl 3 ·xH 2 O was dissolved in acetic acid aqueous solution and magnetically stirred to obtain a uniform brown solution A,

[0072] 2. Dissolve 1,3,5-trimesic acid in absolute ethanol and stir magnetically to obtain a clear and transparent solution B;

[0073] 3. Pour the solution B obtained in step 2 into the solution A obtained in step 1, stir evenly with magnetic force, then transfer it to a polytetrafluoroethylene reactor, control the temperature at 160°C-180°C, keep it for 24-72h, and the reaction is over Afterwards, the product was naturally cooled to room temperature, and centrifuged to obtain a solid substance;

[0074] 4. Use deionized water and ethanol to wash the solid matter obtained in step 3 multiple times, and then dry it to obtain a Ru / C nanoassembly with a sponge-like structure, and the chemical ...

specific Embodiment approach 2

[0075] Specific embodiment two: the difference between this embodiment and specific embodiment one is: in step one, RuCl 3 ·xH 2 The concentration of O is 0.1-0.5 mol / L. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0076] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: in step one, RuCl 3 ·xH 2 The concentration of O is 0.357mol / L. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com