Method for preparing 1-chloro-1-acetylcyclopropylamine by continuous flow reaction

A kind of cyclopropylamine and reaction technology, which is applied in the field of pesticide intermediate preparation to achieve the effects of reducing contact time and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

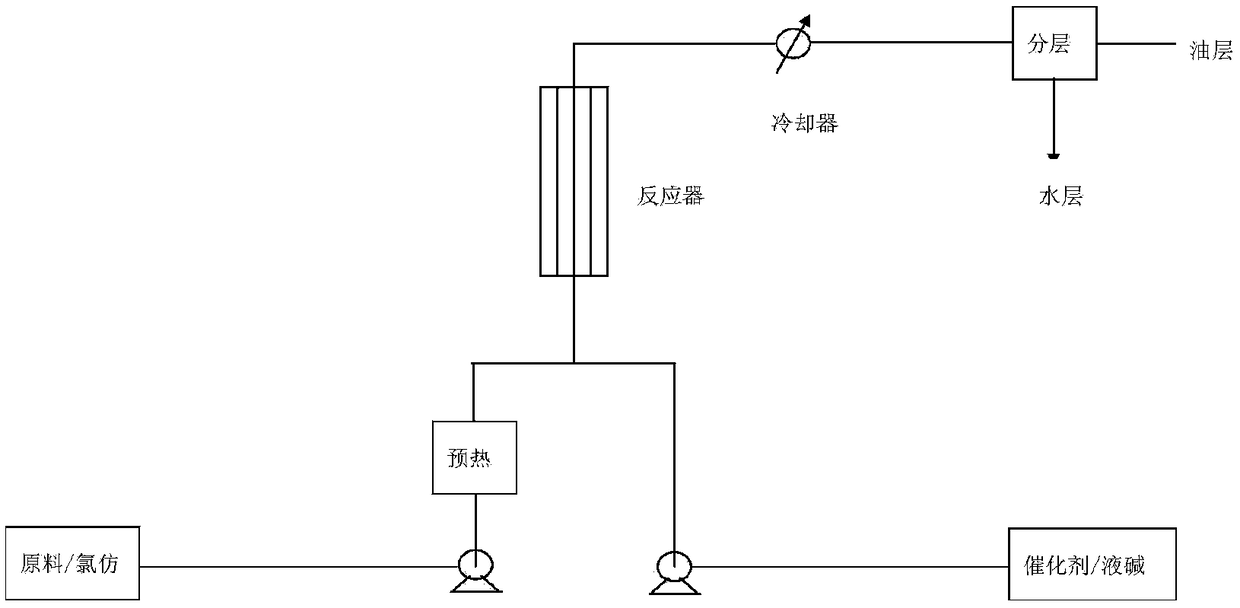

Method used

Image

Examples

Embodiment 1

[0023] Mix 3,5-dichloro-2-pentanone and chloroform to form a solution with a mass concentration of 25%, preheat to 30-40°C, and mix tetramethylammonium chloride, NaOH, H2O with a mass ratio of 4.3:20 : 80 into an aqueous solution. Two metering pumps are used to pump the organic matter and the aqueous solution respectively, and the speeds are 4.4g / min and 4.3g / min respectively. The reaction residence time is 10 seconds, the reaction temperature is 55-58° C., and the reaction liquid is rapidly cooled to 20-30° C. through a condenser for oil-water separation. The oil layer was analyzed by GC; the conversion of the raw materials was complete, the purity of the product after deducting the solvent was 98.8%, and the fractional product content of the external standard was 19.7%. Quantitative yield 97.5%. The reaction material was collected for 24 hours, the oil layer was separated, washed with water, and the solvent was distilled off to obtain 1183 g of a colorless oil layer with a...

Embodiment 2

[0025] Mix 3,5-dichloro-2-pentanone and chloroform to form a solution with a mass concentration of 25%, preheat to 30-40°C, and mix tetramethylammonium chloride, NaOH, H2O with a mass ratio of 4.3:20 : 80 into an aqueous solution. Two metering pumps are used to pump the organic matter and the aqueous solution respectively, and the speeds are 4.4g / min and 4.3g / min respectively. The reaction residence time is 10 seconds, the reaction temperature is 40-45° C., and the reaction liquid is quickly cooled to 20-30° C. through the condenser for oil-water separation. The oil layer was analyzed by GC; the remaining 6% was deducted from the solvent raw material, the product purity was 93.8%, and the product content of the external standard was 18.2%. Quantitative yield 90%.

Embodiment 3

[0027] Mix 3,5-dichloro-2-pentanone and chloroform to form a solution with a mass concentration of 25%, preheat to 30-40°C, and mix tetramethylammonium chloride, NaOH, H2O with a mass ratio of 4.3:30 : 70% water to make a solution. Two metering pumps are used to pump the organic matter and the aqueous solution respectively, and the speeds are 4.4g / min and 1.9g / min respectively. The reaction residence time is 10 seconds, the reaction temperature is 55-58° C., and the reaction liquid is rapidly cooled to 20-30° C. through a condenser for oil-water separation. GC analysis; after deducting the remaining 10% of the solvent raw material, the product purity is 89.1%, and the external standard fractional product content is 17.2%. The quantitative yield was 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com