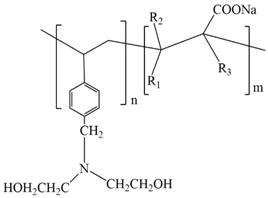

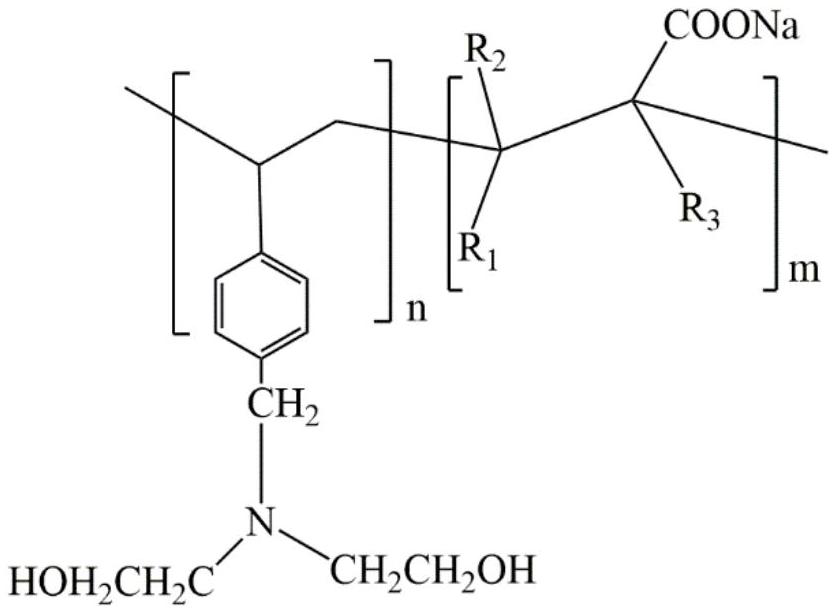

A polymer debonding agent for ceramic slurry with good grinding aid effect

A ceramic slurry and polymer technology, applied in the field of ceramic additives, can solve the problems of narrow application range and low dissolving efficiency, and achieve the effects of improving dissolving performance, simple operation and shortening ball milling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A polymer debonding agent for ceramic slurry with good grinding aid effect, in parts by mass, the preparation method of which comprises the following steps:

[0031] (1) Synthesis of p-diethanolaminomethylstyrene: under nitrogen, add 65 parts of diethanolamine and 100 parts of ethyl acetate into the reaction device, stir and mix evenly, then heat to 50°C, and slowly add 90 parts of p-chloromethylstyrene were added dropwise, and the dropwise addition was completed in 4 hours. After the dropwise addition, the temperature was continued for 2 hours, and then the solvent and impurities were distilled off under reduced pressure to obtain p-diethanolaminomethylstyrene.

[0032] (2) Water-based free radical polymerization: under nitrogen, mix 24 parts of p-diethanolaminomethylstyrene, 14 parts of mesaconic acid, 0.8 parts of dodecyl mercaptan, and 33 parts of water, and add them to the reaction kettle and heat to 80°C at the same time, and then slowly dropwise add 8 parts of an...

Embodiment 2

[0035] A polymer debonding agent for ceramic slurry with good grinding aid effect, in parts by mass, the preparation method of which comprises the following steps:

[0036] (1) Synthesis of p-diethanolaminomethylstyrene: under nitrogen, add 45 parts of diethanolamine and 80 parts of acetone into the reaction device, stir and mix evenly, then heat to 70°C, and slowly drop 60 parts of p-chloromethyl styrene were added dropwise in 2 hours, and the temperature was continued for 1 hour after the dropwise addition, and then the solvent and impurities were removed by distillation under reduced pressure to obtain p-diethanolaminomethyl styrene.

[0037](2) Water-based free radical polymerization: under nitrogen, mix 30 parts of p-diethanolaminomethylstyrene, 10 parts of dimethylmaleic anhydride, 1.5 parts of ferrous sulfate, and 30 parts of water, and add them to the reaction kettle , and heated to 85°C at the same time, and then slowly dropwise added 5 parts of an aqueous solution of...

Embodiment 3

[0040] A polymer debonding agent for ceramic slurry with good grinding aid effect, in parts by mass, the preparation method of which comprises the following steps:

[0041] (1) Synthesis of p-diethanolaminomethylstyrene: under nitrogen, add 53 parts of diethanolamine and 86 parts of butanone into the reaction device, stir and mix evenly, then heat to 59°C, and slowly drop into it Add 70 parts of p-chloromethyl styrene, drop it in 3 hours, continue to keep warm for 1.5 hours after dropping it, then distill off the solvent and impurities under reduced pressure to obtain p-diethanolaminomethyl styrene.

[0042] (2) Water-based free radical polymerization: under the condition of nitrogen, 20 parts of p-diethanolaminomethylstyrene, 15 parts of citraconic anhydride, 0.5 parts of thiourea, and 40 parts of water were mixed evenly, added to the reaction kettle, and heated at the same time to 75°C, then slowly add 10 parts of an aqueous solution of azobiscyanovaleric acid with a mass fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com