Manganese-based luminous metal organic framework material as well as preparation method and application thereof

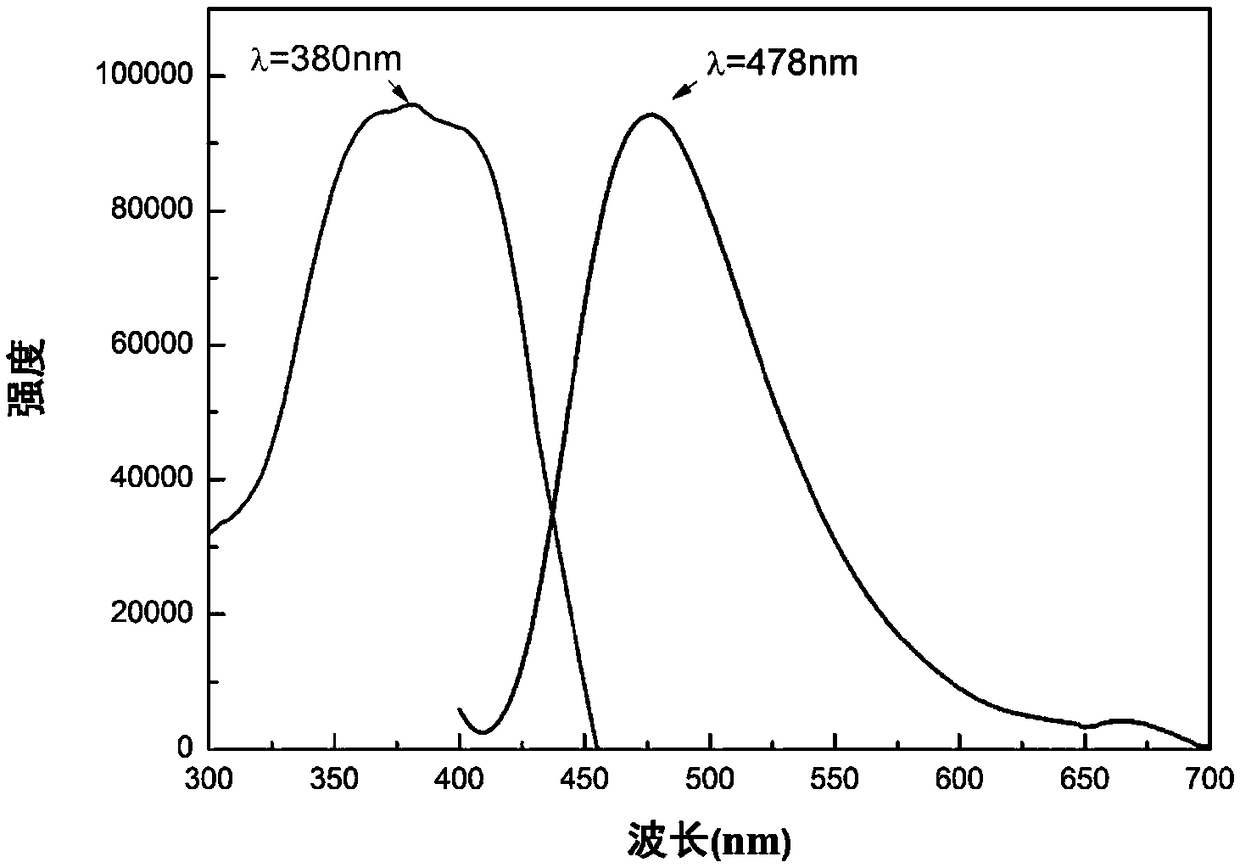

A metal-organic framework and manganese-based technology, applied in luminescent materials, material analysis by optical means, material analysis, etc., to achieve the effects of high fluorescence quantum yield, simple preparation method, excellent fluorescence performance and photoluminescence efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

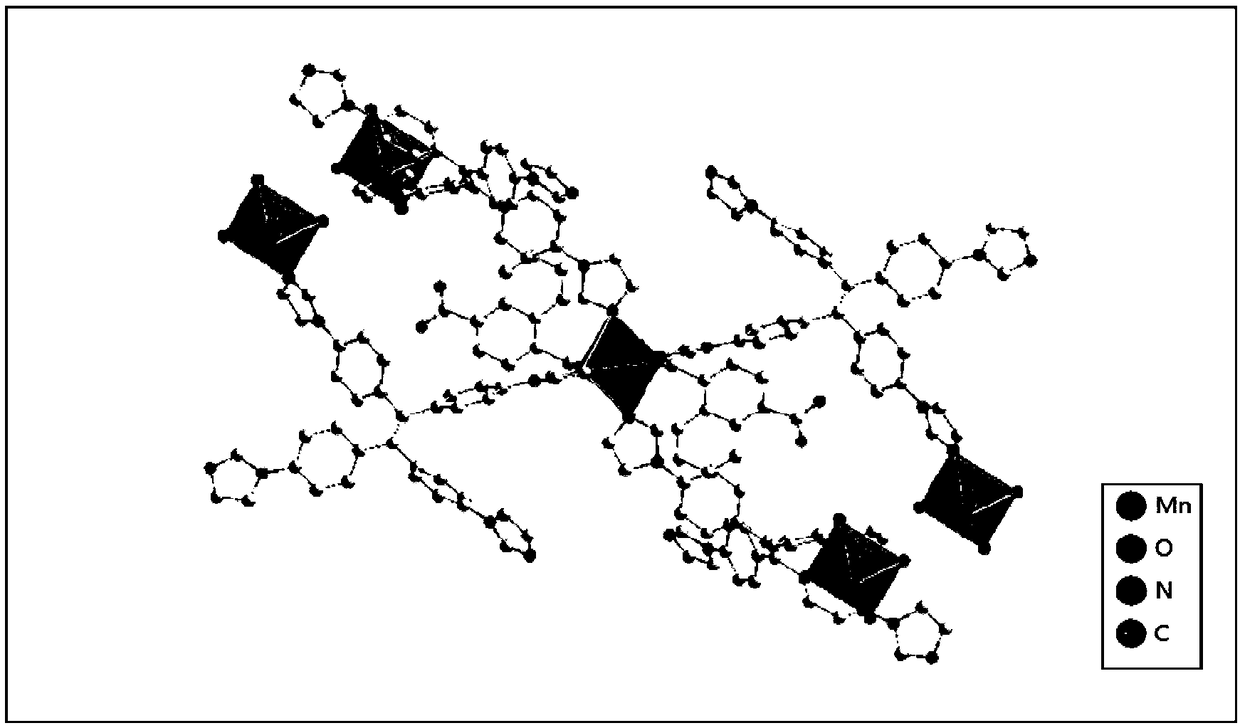

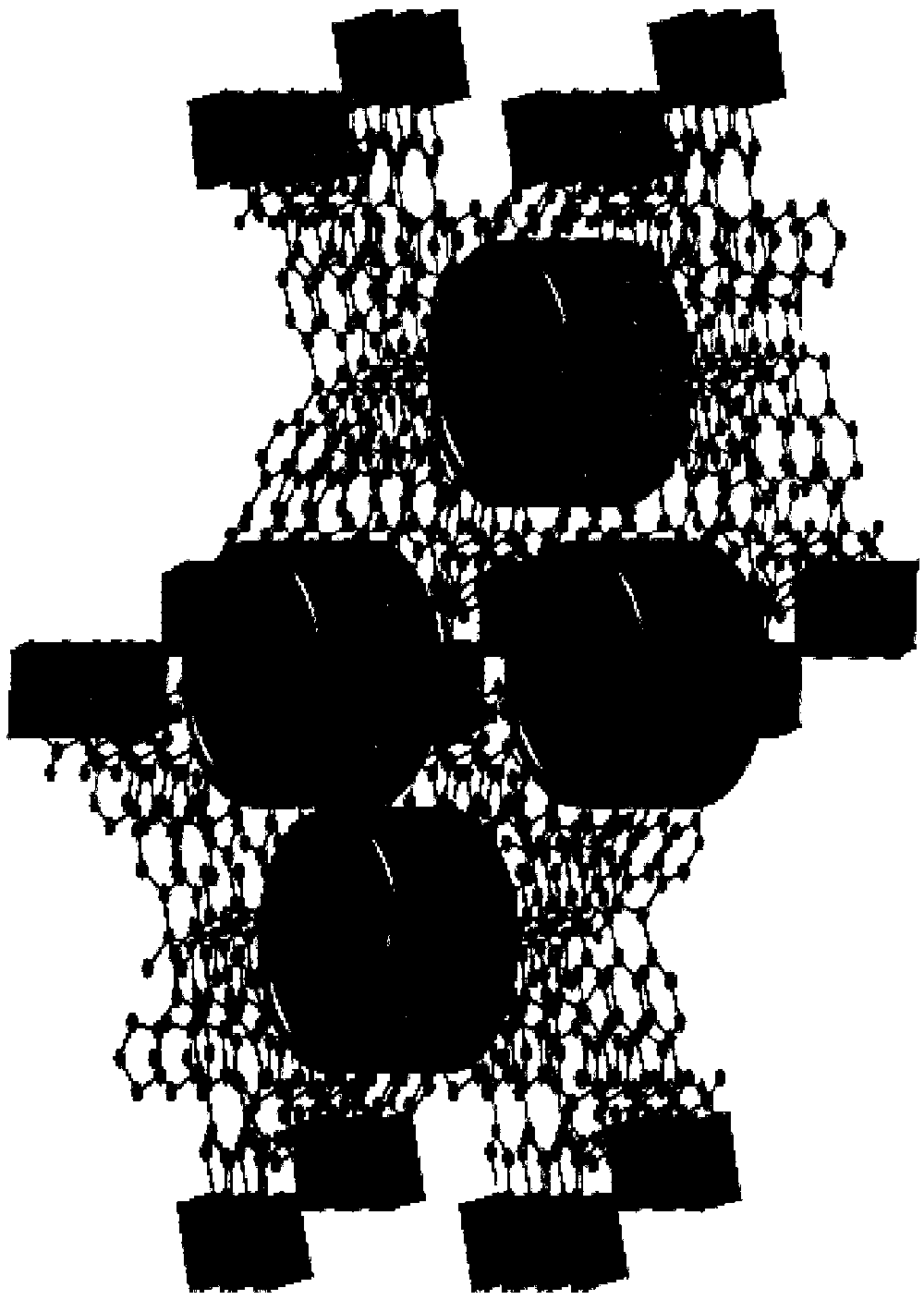

[0040] Example 1 Manganese-based luminescent metal-organic framework {[Mn(tipe)(1,4-ndc)(H 2 O)] (DMF) 2 ·(H 2 O) 3} n Synthesis

[0041] Accurately weigh 0.03mmol of manganese chloride tetrahydrate, 0.01mmol of 1,1,2,2-tetra[4-(imidazol-1-yl)phenyl]ethylene and 0.02mmol of 1,4-naphthalene dicarboxylic acid in proportion to Add 1mL of N,N-dimethylformamide and 1mL of water to the glass tube, and ultrasonically dissolve until the solution becomes clear. Seal the glass tube and put it in a constant temperature drying oven. A manganese-based luminescent metal-organic framework material is obtained.

Embodiment 2

[0042] Example 2 Manganese-based luminescent metal-organic framework {[Mn(tipe)(1,4-ndc)(H 2 O)] (DMF) 2 ·(H 2 O) 3} n Synthesis

[0043] Accurately weigh 0.06mmol of manganese chloride tetrahydrate, 0.02mmol of 1,1,2,2-tetra[4-(imidazol-1-yl)phenyl]ethylene and 0.04mmol of 1,4-naphthalene dicarboxylic acid in proportion to Add 2mL of N,N-dimethylformamide and 2mL of water to the glass tube, ultrasonically dissolve until the solution becomes clear, seal the glass tube and put it in a constant temperature drying oven, react at 85°C for 72h, cool down to room temperature naturally, filter The same manganese-based light-emitting metal-organic framework material as in Example 1 was obtained.

Embodiment 3

[0044] Example 3 Manganese-based luminescent metal-organic framework {[Mn(tipe)(1,4-ndc)(H 2 O)] (DMF) 2 ·(H 2 O) 3} n Synthesis

[0045] Accurately weigh 0.3mmol of manganese chloride tetrahydrate, 0.1mmol of 1,2,2-tetrakis[4-(imidazol-1-yl)phenyl]ethylene and 0.2mmol of 1,4-naphthalene dicarboxylic acid into a glass bottle Add 10mL of N,N-dimethylformamide and 10mL of water, ultrasonically dissolve until the solution becomes clear, put it in a constant temperature drying oven, react at 95°C for 72h, cool down to room temperature naturally, and filter to obtain the same solution as in Example 1. Manganese-based luminescent metal-organic frameworks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com