Expansion type boron-nitrogen-phosphorus compound fire retardant and preparation method thereof

A technology of intumescent flame retardant and compound flame retardant, which is applied in the field of flame retardant preparation, can solve problems such as limited use range and melt droplets, and achieves anti-melt droplet generation, less addition, and high flame retardant efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

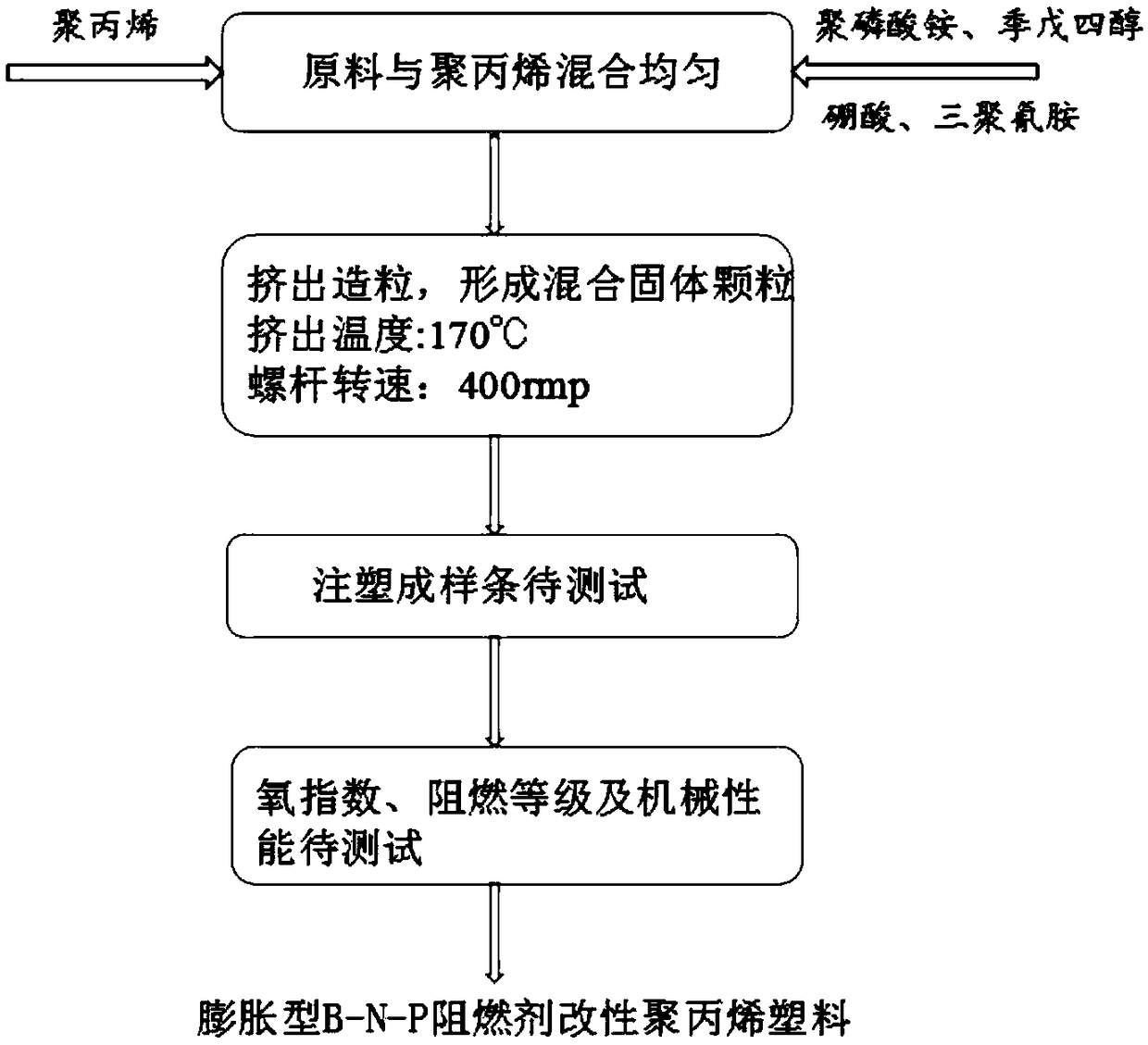

[0022] Such as figure 1 , the preparation method of intumescent boron-nitrogen-phosphorous compound flame retardant of the present invention, comprises the following steps:

[0023] (1) Mix intumescent flame retardant and polypropylene in a high-speed mixer according to a certain compounding ratio;

[0024] (2) Use a twin-screw extruder to extrude and granulate to form mixed solid particles;

[0025] (3) Use the injection molding machine to inject solid particles into test specimens, and measure the LOI value and UL-94 value;

[0026] (4) Modify the intumescent flame retardant and repeat steps 1-4;

[0027] (5) Select the best flame retardant formula, and test the physical properties of the modified flame retardant polypropylene.

Embodiment 1

[0029] Weigh ammonium polyphosphate, pentaerythritol, boric acid and melamine according to the mass ratio of 2:1:1:1, mix them with polypropylene in an amount of 30wt%, and mix them evenly in a high-speed mixer. The rotational speed of the twin-screw extruder was set to 400rmp, the outlet temperature was set to 170°C, and the mixed flame retardant material was added to the twin-screw extruder for granulation to form solid mixed granules. The solid pellets were injection molded into test specimens using an injection molding machine.

Embodiment 2

[0030] Example 2: Testing the flame retardancy and mechanical properties of the intumescent boron-nitrogen-phosphorus compound flame retardant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com