Hemp beer and making method thereof

A beer and hemp technology, applied in the field of brewing technology, can solve the problems of hemp oil formulation, maximum THC content limit, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

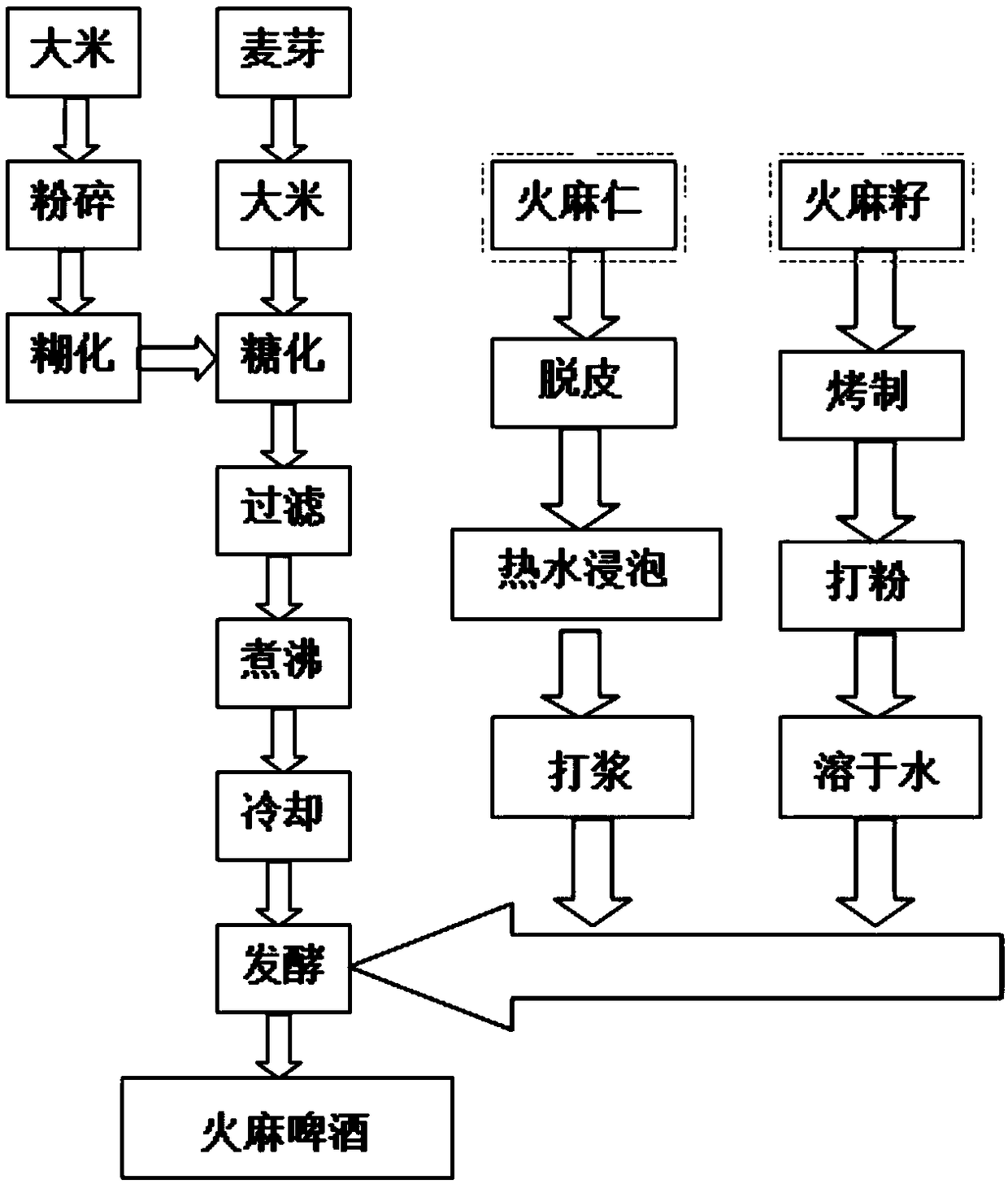

[0039] A preparation method of hemp beer, the steps are as follows:

[0040] The processing of hemp seeds: the steps are peeling, selection, rinsing, hot water soaking, beating, cooling and fine filtration.

[0041] Processing of hemp seeds: After the hemp seeds are roasted, they are powdered and mixed evenly with water.

[0042] Preparation of wort: After the malt is crushed, it is immersed in the mash pot for saccharification. After the rice is crushed, it is put into the mash pot for gelatinization. The saccharification liquid is filtered, and the filtered saccharification liquid enters the boiling pot for boiling, and the feeding ratio of malt to rice is 9:5.

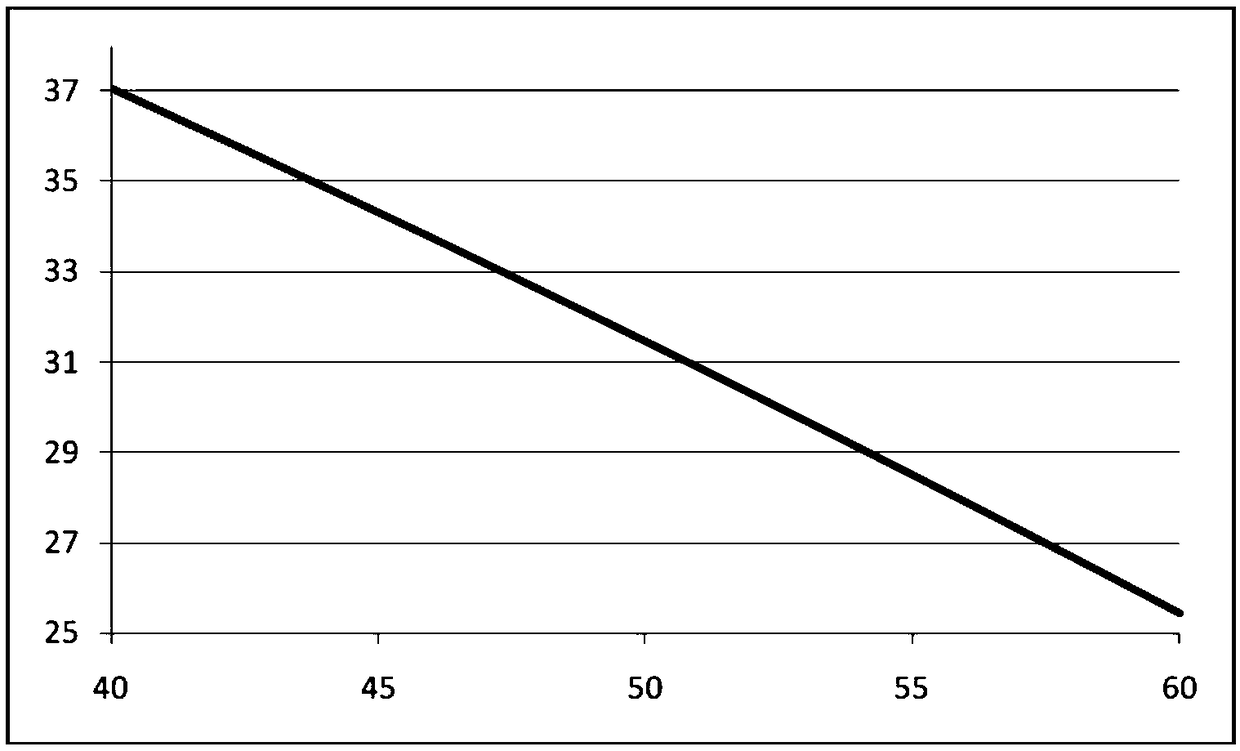

[0043] The technical conditions of the gelatinization process are: temperature control at 52°C for 30 minutes, 60°C for 20 minutes, boiling for 30-60 minutes; material moisture content of 30%; adding lactic acid, high temperature resistant amylase and the like.

[0044] The technological conditions of the sacchari...

Embodiment 2

[0050] A kind of production method of hemp beer, process step is as follows:

[0051] (1) Processing of hemp seeds: select 20-30 parts of hemp seeds, and the steps are successively peeling, selection, washing, hot water soaking, beating, cooling and fine filtration.

[0052] (2) Processing of hemp seeds: select 15-20 parts of hemp seeds, grind the hemp seeds into powder after roasting, and mix evenly with water.

[0053] (3) Preparation of wort: After the malt is crushed, it is immersed in the mash pot for saccharification. After the rice is crushed, it enters the mash pot for gelatinization. Finally, the saccharified liquid is filtered, and the filtered saccharified liquid enters the boiling pot to be boiled, and the feeding ratio of malt to rice is 9:5.

[0054] (4) Fermentation: mix the processed hemp seeds and hemp seed liquid with the cooled wort, and add yeast to ferment.

[0055] The moisture content of the material during gelatinization and saccharification is 30%. ...

Embodiment 3

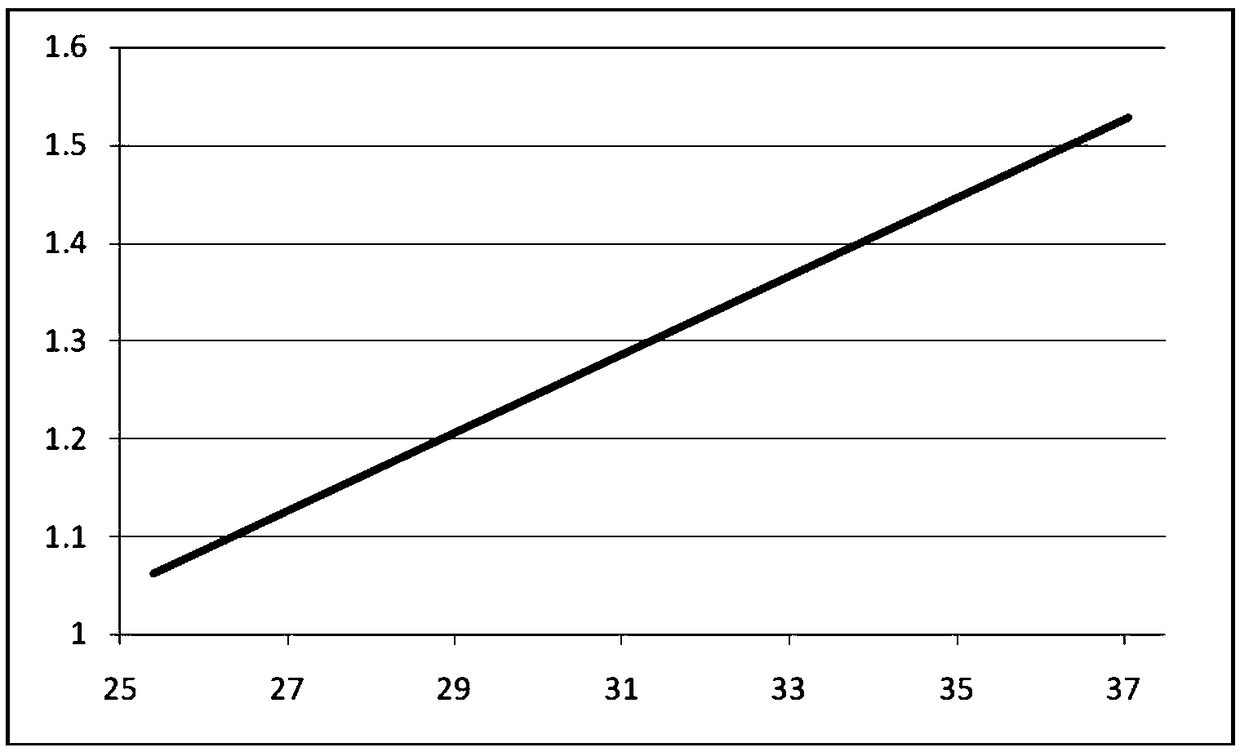

[0060] The invention relates to hemp beer, which comprises the steps of selecting, rinsing, peeling, soaking in hot water, adding water and beating the hemp seeds to prepare the hemp seed slurry; roasting the hemp seeds, powdering them, and adding water to dissolve them. Weigh 80kg of rice, crush it and add 240kg of water for gelatinization. During gelatinization, add a small amount of lactic acid, high temperature resistant enzyme and edible gypsum powder. The gelatinization temperature is 52°C for 30min, 60°C for 20min, and boil for 60min. Weigh 60kg of malt, crush it, add 180kg of water, mix it with gelatinized rice, add dextranase, lactic acid, and edible gypsum powder, and carry out saccharification. The saccharification temperature is 28°C for 30 minutes, 33°C for 60 minutes, and 56°C 60min, 65°C for 2h. Add hops, carrageenan, and nutrient salts, add hops in 3 times, and boil for 2 hours. After cooling, adjust the yeast for fermentation. The fermentation process paramet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com