Cannon barrel foam copper removal wiping agent and preparing method and application thereof

A technology for gun barrels and wipers, applied in cleaning methods and utensils, chemical instruments and methods, and cleaning hollow objects, etc., can solve problems such as environmental hazards to operating workers, unsatisfactory cleaning effects, and poor stability of wipers, and achieve cost savings Inexpensive, easy to operate, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention also provides a preparation method of a foam copper-removing wiping agent for artillery barrels, which is characterized in that the steps are:

[0033] (a) Dissolve ammonium carbonate, red vitriol, sodium hydroxide, surfactant and sodium silicate in water, and heat to 50-60°C;

[0034] (b) Add ammonia water, continue to heat and stir, and keep warm for 2-3 hours, after natural cooling, the foam copper removal wiper is obtained.

[0035] The wiping agent prepared by the present invention is in the form of foam, and can completely contact with the inner wall of the gun barrel during use, because the wiping agent can effectively remove residues on the inner surface of the gun bore after the cannon is fired, and has antirust performance, and at the same time, the product and raw materials are safe, and the The harm to the environment and the human body is small. Therefore, the above-mentioned foam copper-removing wiper is applied to the wiping maintena...

Embodiment 1

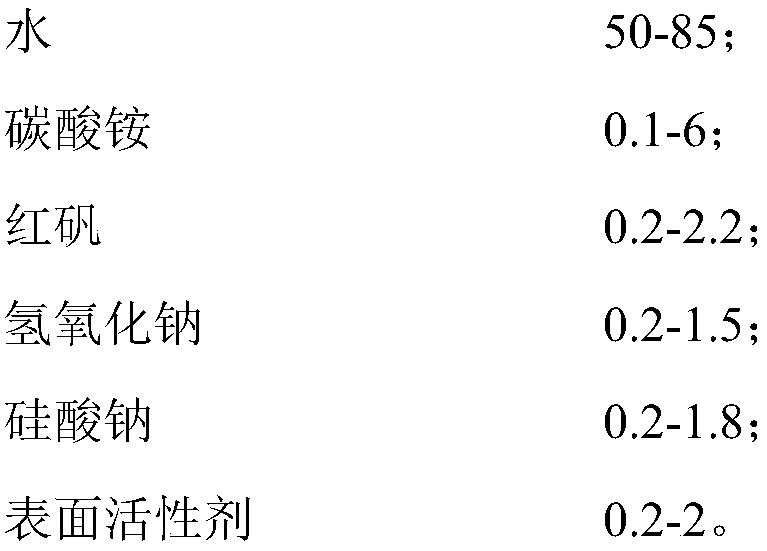

[0037] A kind of copper-removing wiping agent of artillery barrel foam, its parts by weight are composed as follows:

[0038]

[0039] Preparation method: Taking the preparation of the artillery barrel foam copper-removing wiper as an example, the preparation method of the artillery barrel foam copper-removing wiper provided in this embodiment is described as follows:

[0040] (a) Dissolve 0.3 part of ammonium carbonate, 0.6 part of red alum, 0.7 part of sodium hydroxide, 0.4 part of sodium dodecylbenzenesulfonate, and 0.4 part of sodium silicate in 54 parts of water, and heat to 50°C;

[0041] (b) Add 1.2 parts of ammonia water, continue to heat and stir, to 50°C and keep warm for 3 hours, after natural cooling, the foam copper removal wiper is obtained.

[0042] When the foam-like copper-removing wiper is used in the wiping and maintenance of the barrel after the gun is fired and in the daily maintenance of the gun, the foam-like copper-removing wiper can completely conta...

Embodiment 2

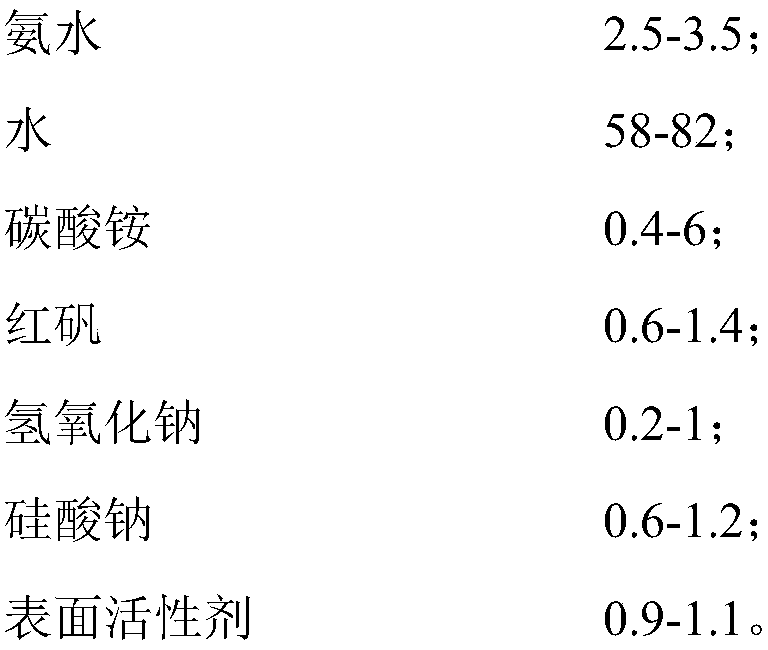

[0044] A kind of copper-removing wiping agent of artillery barrel foam, its parts by weight are composed as follows:

[0045]

[0046]

[0047] Preparation method: Taking the preparation of the artillery barrel foam copper-removing wiper as an example, the preparation method of the artillery barrel foam copper-removing wiper provided in this embodiment is described as follows:

[0048] (a) Dissolve 0.8 parts of ammonium carbonate, 1.4 parts of red alum, 1.2 parts of sodium hydroxide, 1.1 parts of sodium lauryl sulfate, and 1.2 parts of sodium silicate in 66 parts of water, and heat to 55°C;

[0049] (b) Add 2 parts of ammonia water, continue to heat and stir, to 55°C and keep warm for 2.5h, after natural cooling, the foam copper removal wiper is obtained.

[0050] When the foam-like copper-removing wiper is used in the wiping and maintenance of the barrel after the gun is fired and in the daily maintenance of the gun, the foam-like copper-removing wiper can completely co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com