Composite electronic conductive agent for thermal battery positive electrode material

A technology of electronic conduction and positive electrode material, applied in battery electrodes, circuits, electrical components, etc., can solve the problem of low utilization rate and discharge capacity of thermal batteries, and achieve the effect of inhibiting thermal decomposition, improving electrical conductivity, and high electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

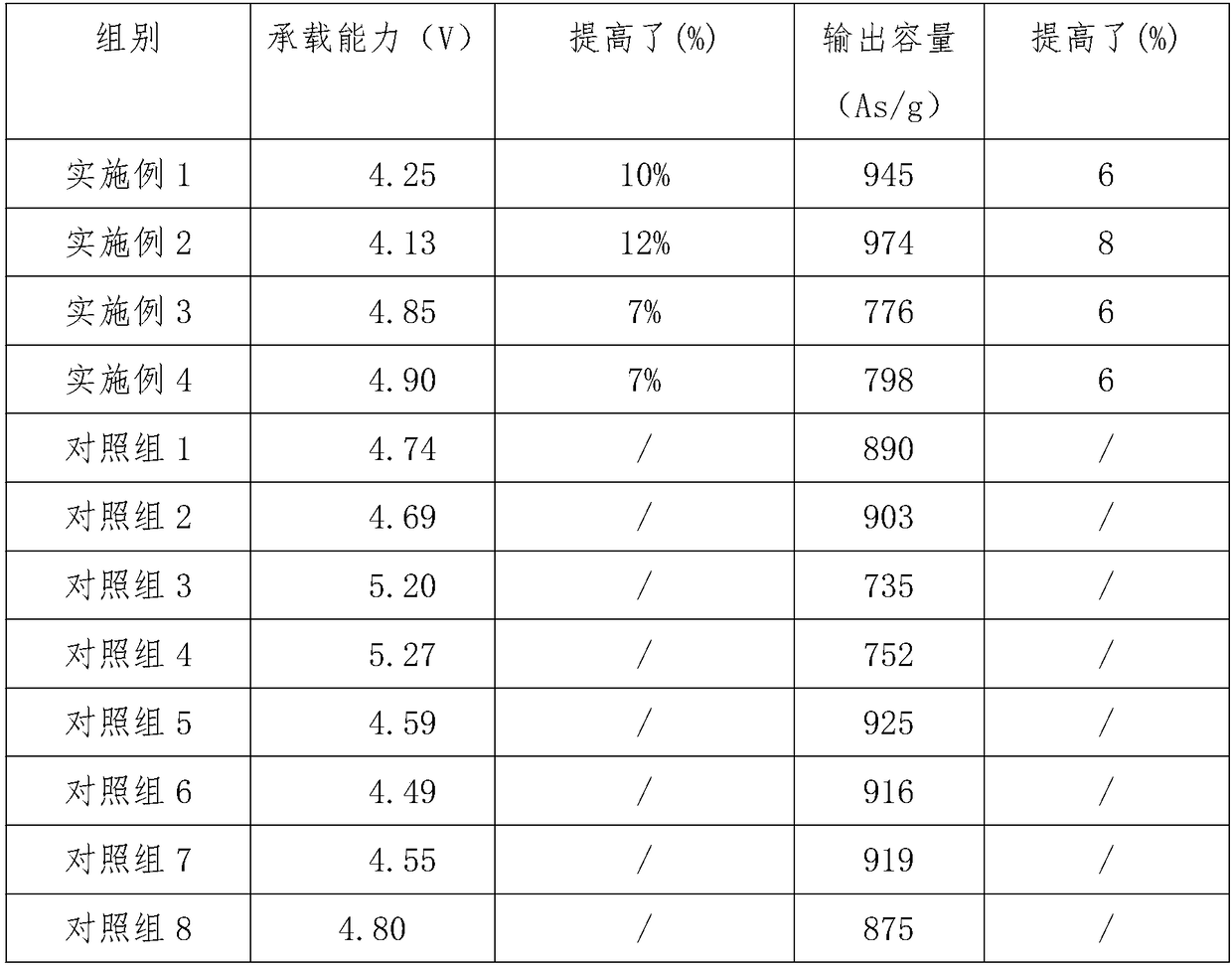

Examples

Embodiment 1

[0018] (1) Pre-extraction of metal powder: First, put iron powder, cobalt powder and nickel powder separately in a ball mill tank with a protective atmosphere for ball milling for 2h to 6h, take it out, add acid to dissolve it, and prepare it with surfactant, lye, iron, etc. or cobalt or nickel, a kind of metal soluble salt solution, wherein the concentration of lye is 0.3%, the metal powder is oscillated and rinsed, and after repeated rinsing for 3 times, it is heated to obtain a 10 μm ultrafine powder; (2) Grinding: first weigh the obtained iron powder, cobalt powder and nickel powder ultrafine powder according to the percentage ratio of 45:45:10, and ball mill in a ball mill tank with a protective atmosphere for 30 minutes to 60 minutes in an environment with a humidity environment less than 3%. The composite powder material is obtained, and then the composite powder is dried under vacuum at 120°C for 6 hours to obtain a composite electronic conductive agent for the positive...

Embodiment 2

[0020] Among them, iron powder, cobalt powder and nickel powder are weighed according to the percentage of 20:35:45, and the positive electrode material is Co 0.5 Ni 0.5 S 2 , the addition ratio of conductive agent is 2.5%, and other operation steps are identical with embodiment 1;

Embodiment 3

[0022] Among them, iron powder, cobalt powder and nickel powder are weighed according to the percentage of 20:45:35, and the positive electrode material is CoS 2 , the addition ratio of conductive agent is 3%, and other operation steps are identical with embodiment 1;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thermal stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com