Probiotic green papaya milk powder and preparation method thereof

The technology of green papaya and probiotics is applied in the directions of milk preparations, bacteria used in food preparation, dairy products, etc., which can solve problems such as lack of preparation performance and flavor, and achieve the effects of good preparation and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

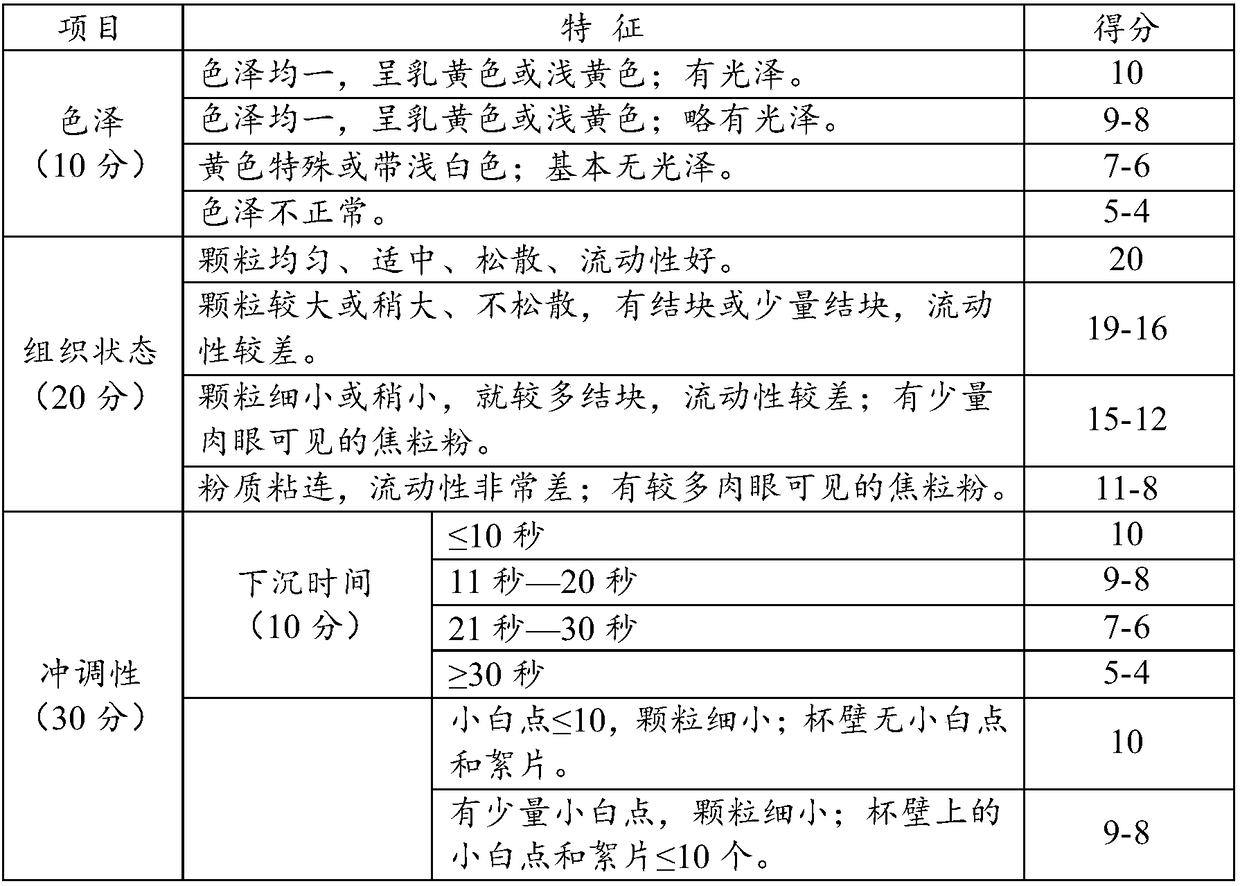

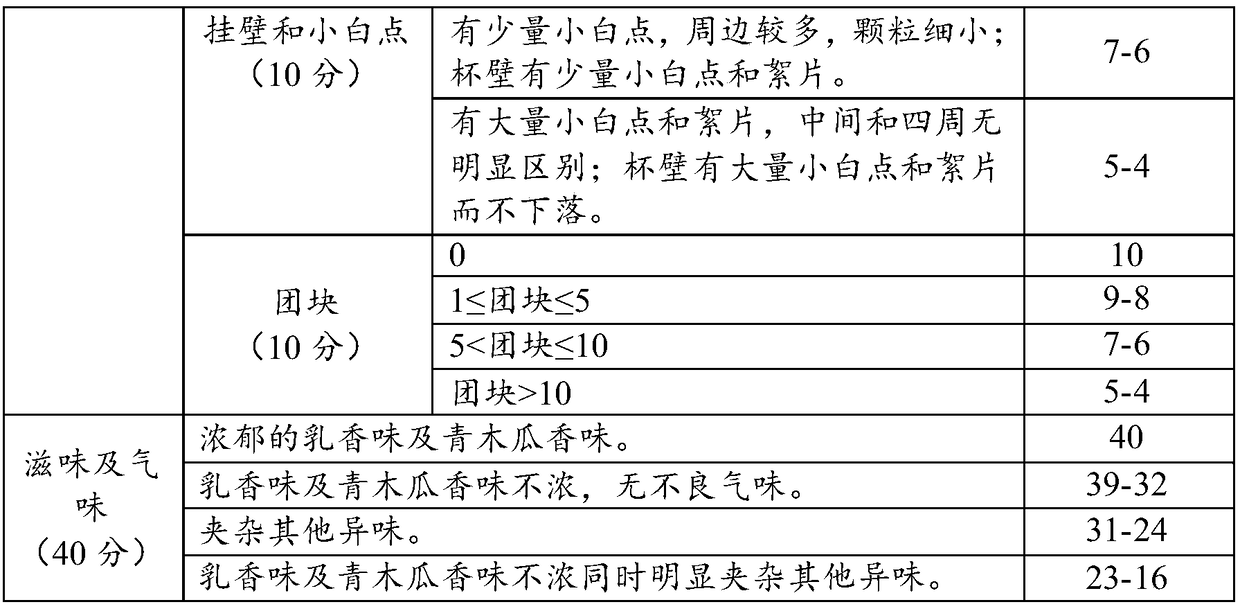

Image

Examples

Embodiment 1

[0065] Step 1: Pass 400 parts of whole milk powder, 180 parts of D90 desalted whey powder, 195 parts of 34% concentrated whey protein powder, 100 parts of skimmed milk powder, 60 parts of polydextrose, and 53 parts of green papaya powder through an 8-mesh vibrating sieve, Mix well, get mixed powder, set aside.

[0066] Step 2: Pass 11 parts of nutritional enhancer, 0.068 parts of quadruple compound bacteria, and 0.04 parts of Lactobacillus plantarum through an 8-mesh vibrating sieve, mix them evenly with the mixed powder, and seal the package to obtain the obtained product.

Embodiment 2

[0068] Step 1: Pass 350 parts of whole milk powder, 275 parts of D90 desalted whey powder, 175 parts of 34% concentrated whey protein powder, 75 parts of skimmed milk powder, 70 parts of polydextrose, and 40 parts of green papaya powder through an 8-mesh vibrating sieve, Mix well, get mixed powder, set aside.

[0069] Step 2: Pass 14 parts of nutritional enhancer, 0.084 parts of quadruple compound bacteria, and 0.025 parts of Lactobacillus plantarum through an 8-mesh vibrating sieve, mix them evenly with the mixed powder, and seal the package to obtain the obtained product.

Embodiment 3

[0071] Step 1: Pass 250 parts of whole milk powder, 310 parts of D90 desalted whey powder, 220 parts of 34% concentrated whey protein powder, 55 parts of skimmed milk powder, 83 parts of polydextrose, and 60 parts of green papaya powder through an 8-mesh vibrating sieve, Mix well, get mixed powder, set aside.

[0072] Step 2: Pass 21 parts of nutritional enhancer, 0.1 part of quadruple compound bacteria, and 0.001 part of Lactobacillus plantarum through an 8-mesh vibrating sieve, mix them evenly with the mixed powder, and seal the package to obtain the obtained product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com