Sustained-release formulation of nano-zinc green tea coated with n-butyl cyanoacrylate and its application

A technology of n-butyl cyanoacrylate and slow-release preparations, which is applied in the field of sustained-release preparations of nano-zinc green tea wrapped in n-butyl cyanoacrylate, to achieve the effects of improving bioavailability, increasing solubility, and enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

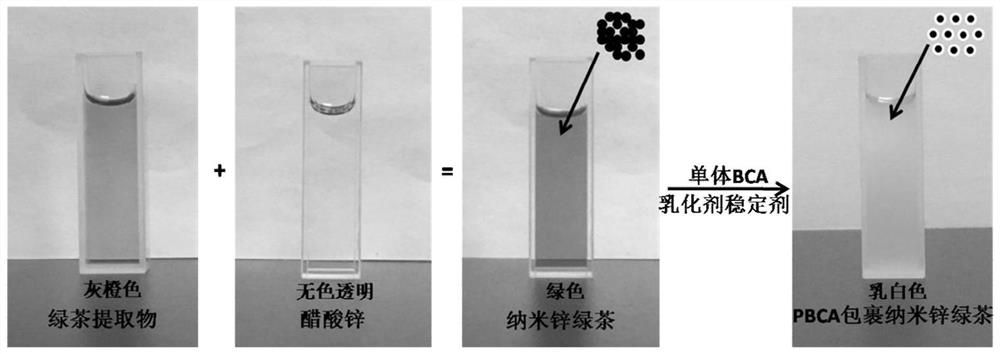

[0048] Preparation of nano-zinc green tea sustained-release preparation coated with n-butyl cyanoacrylate

[0049] (1) Preparation of Nano Zinc Green Tea

[0050] Grind the green tea leaves, weigh 10g of green tea powder and put it into 200mL of ultrapure water, stir it magnetically at 1000r / min for 1h, then pass it through 8μm grade filter paper and 220nm grade filter membrane to obtain the green tea extract, then add 0.10 The mol / L zinc acetate ultrapure aqueous solution is dripped dropwise into the green tea extract that is being continuously stirred (1000r / min) with a volume ratio of 1:1. liquid, the nano-zinc green tea crude liquid is centrifuged 3 times, and the obtained solids are dispersed in ultrapure water for freezing and freeze-drying to obtain a nano-zinc green tea freeze-dried powder;

[0051] (2) Preparation of poly(n-butyl cyanoacrylate) coated nano-zinc green tea sustained-release preparation

[0052] Prepare the organic phase mixture: disperse 3.0 mg of nan...

Embodiment 2

[0065] Preparation of nano-zinc green tea sustained-release preparation coated with n-butyl cyanoacrylate

[0066] (1) Preparation of Nano Zinc Green Tea

[0067] Grind the green tea leaves, weigh 10g of green tea powder and put it into 100mL of ultrapure water, stir magnetically at 1000r / min for 2h, then pass through 5μm grade filter paper and 220nm grade filter membrane for vacuum filtration to obtain green tea extract, and then add 0.10 The mol / L zinc acetate ultrapure aqueous solution is dripped dropwise into the green tea extract that is being continuously stirred (1000r / min) with a volume ratio of 1:1. liquid, the nano-zinc green tea crude liquid is centrifuged 3 times, and the obtained solids are dispersed in ultrapure water for freezing and freeze-drying to obtain a nano-zinc green tea freeze-dried powder;

[0068] (2) Preparation of poly(n-butyl cyanoacrylate) coated nano-zinc green tea sustained-release preparation

[0069] Prepare the organic phase mixture: disper...

Embodiment 3

[0076] Preparation of nano-zinc green tea sustained-release preparation coated with n-butyl cyanoacrylate

[0077] (1) Preparation of Nano Zinc Green Tea

[0078] Grind the green tea leaves, weigh 10g of green tea powder and put it into 100mL of ultrapure water, stir magnetically at 1000r / min for 1h, then pass through 6μm grade filter paper and 220nm grade filter membrane for vacuum filtration to obtain green tea extract, and then add 0.10 The mol / L zinc acetate ultrapure aqueous solution is dripped dropwise into the green tea extract that is being continuously stirred (1000r / min) at a volume ratio of 1:2. After biosynthesis reaction at room temperature for 2 hours, the obtained nano-zinc green tea The crude liquid is centrifuged three times with the nano-zinc green tea crude liquid, and the obtained solids are dispersed in ultrapure water for freezing and freeze-drying to obtain the nano-zinc green tea freeze-dried powder;

[0079] (2) Preparation of poly(n-butyl cyanoacryla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| encapsulation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com