Super-long platinum tellurium mesoporous nano-tube electrocatalyst and preparation method thereof

An electrocatalyst, tellurium mesoporous technology, applied in the field of ultra-long platinum tellurium mesoporous nanotube electrocatalyst and its preparation, can solve the problems of mesoporous metal irregularity, complexity, high temperature, etc., and achieve outstanding activity and stability, The effect of simple preparation method and high application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

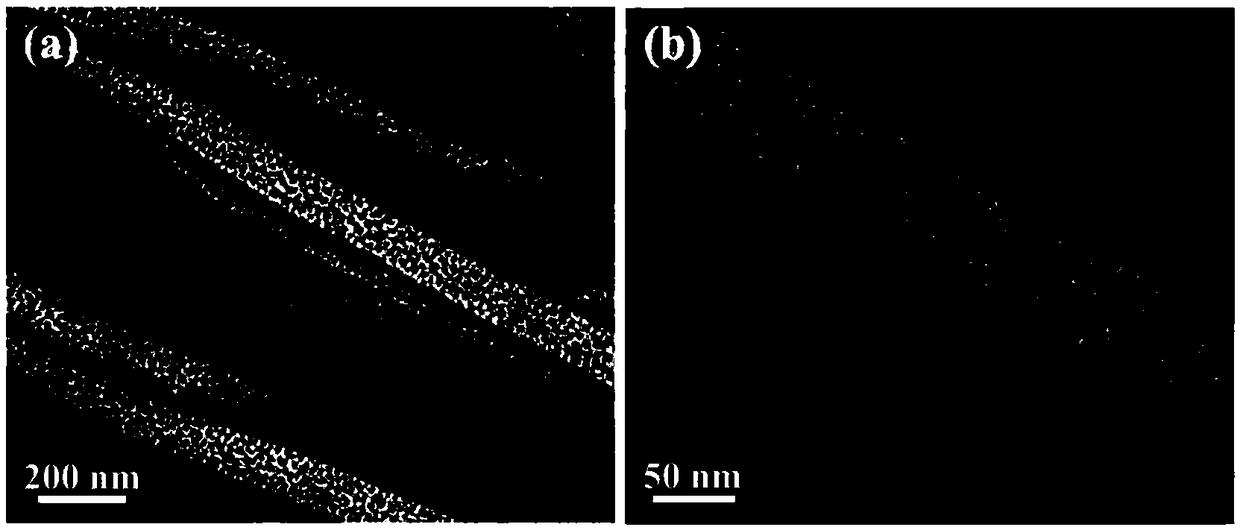

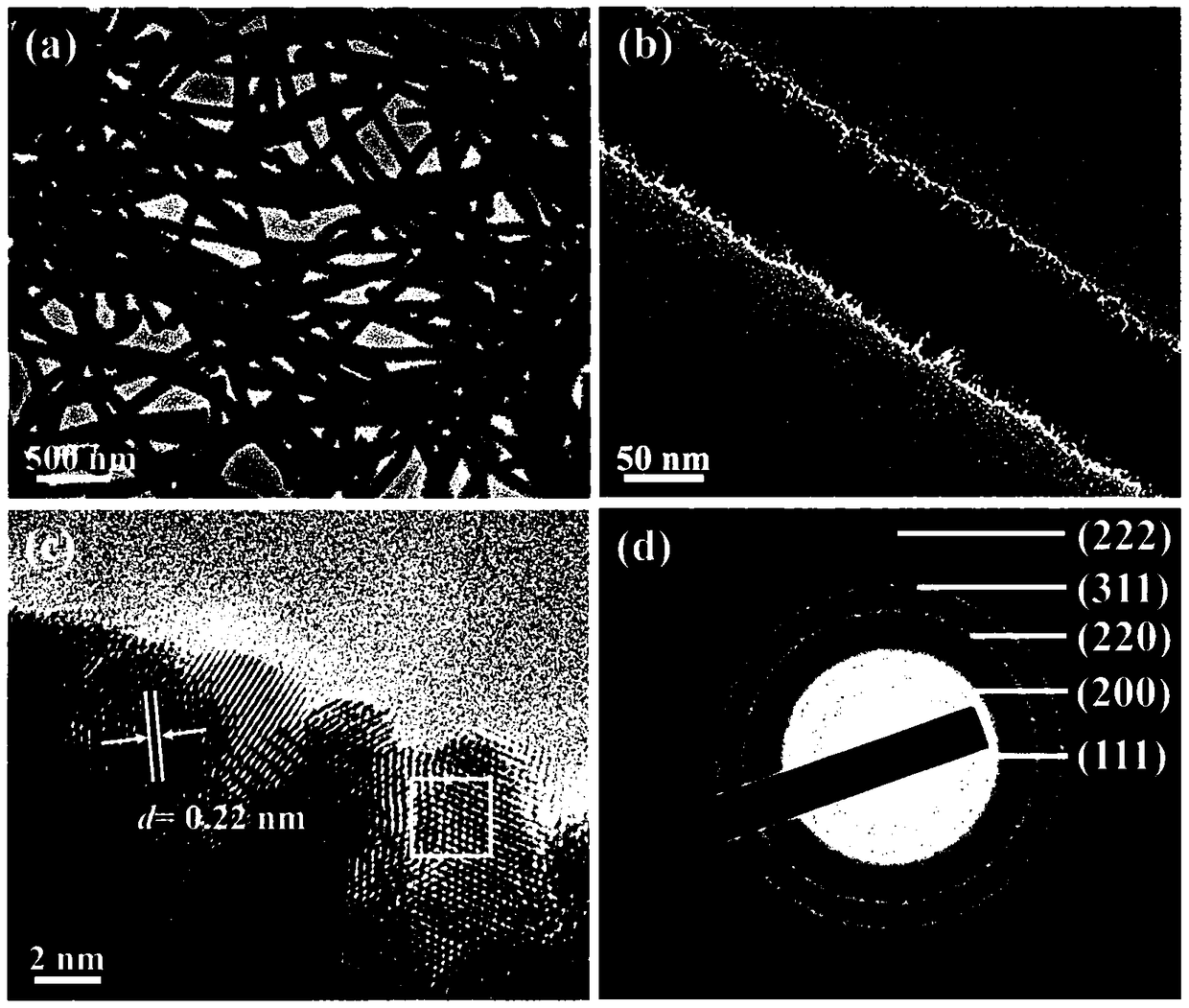

[0039] A preparation method of ultra-long platinum-telluride mesoporous nanotube electrocatalyst, said method comprising the steps of:

[0040] 1) Dissolve 0.092g of sodium tellurite and 1g of PVP in 35.22mL of water under magnetic stirring, then add 1.43mL of hydrazine hydrate and 3.35mL of ammonia water, mix well; place the reaction solution in a high-pressure reactor at 180°C for reaction 3 hours; after the reaction is completed, cool to room temperature, centrifuge with acetone, and wash with water three times to obtain tellurium nanowires; disperse the synthesized tellurium nanowires in 15 mL of water for later use;

[0041] 2) Potassium platinite with a concentration of 20mM and ascorbic acid solution with a concentration of 0.1M were prepared respectively;

[0042] 3) Dissolve 20mg of surfactant F127 in 2mL of potassium platinite solution, then add 0.2mL of tellurium nanowires and 2mL of ascorbic acid solution; the mixture is stirred and reacted at 25°C for 2 hours; aft...

Embodiment 2

[0046] A preparation method of ultra-long platinum-tellurium mesoporous nanotube oxygen reduction catalyst, said method comprising the steps of:

[0047] 1) Dissolve 0.092g of sodium tellurite and 1g of PVP in 35.22mL of water under magnetic stirring, then add 1.43mL of hydrazine hydrate and 3.35mL of ammonia water, mix well; place the reaction solution in a high-pressure reactor at 180°C for reaction 3 hours; after the reaction is completed, cool to room temperature, centrifuge with acetone, and wash with water three times to obtain tellurium nanowires; disperse the synthesized tellurium nanowires in 15 mL of water for later use;

[0048] 2) Potassium platinite with a concentration of 20mM and ascorbic acid solution with a concentration of 0.1M were prepared respectively;

[0049] 3) Dissolve 20mg of surfactant PVP in 2mL of potassium platinite solution, then add 0.2mL of tellurium nanowires and 2mL of ascorbic acid solution; the mixture is stirred and reacted at 25°C for 2 h...

Embodiment 3

[0053] A preparation method of ultra-long platinum-tellurium mesoporous nanotube oxygen reduction catalyst, said method comprising the steps of:

[0054] 1) Dissolve 0.5g of sodium tellurite and 3g of PVP in 50mL of water under magnetic stirring, then add 5mL of hydrazine hydrate and 5mL of ammonia water, and mix well; place the reaction solution in an autoclave at 200°C for 5 hours; After the reaction is completed, cool to room temperature, centrifuge with acetone, and wash with water three times to obtain tellurium nanowires; disperse the synthesized tellurium nanowires in 30 mL of water for later use;

[0055] 2) Potassium platinite with a concentration of 50mM and ascorbic acid solution with a concentration of 0.5M were prepared respectively;

[0056] 3) Dissolve 30mg of surfactant F127 in 5mL of potassium platinite solution, then add 1mL of tellurium nanowires and 5mL of ascorbic acid solution; the mixture is stirred and reacted at 60°C for 5 hours; after the reaction is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com