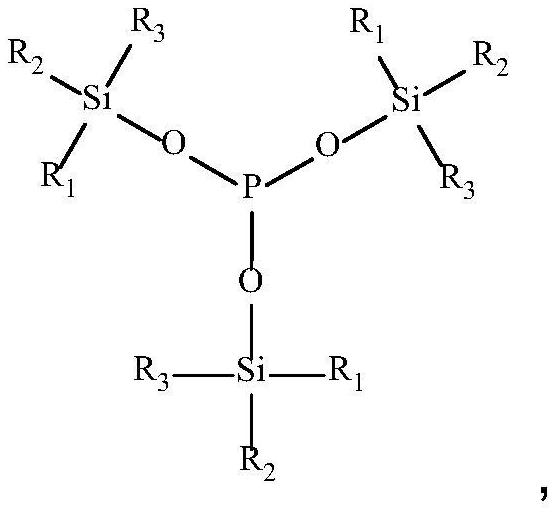

A kind of synthetic method of three (trihydrocarbyl silyl) phosphites

A technology of trihydrocarbyl silicon base and trihydrocarbyl silicon amine, which is applied in the field of triphosphite synthesis to achieve the effects of easy-to-obtain raw materials, simple process route, and safe and environmentally friendly reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The reaction device is equipped with an electric heating mantle, a four-neck flask, an electric stirring rod, a thorn-shaped rectification column, a reflux condenser and a receiving bottle, and the nitrogen gas is inserted into the bottom tube to make nitrogen bubbles purge the reaction device to ensure that the device is dry.

[0038] Add 328g of phosphorous acid and 3480g of N,N-diethyl-N-trimethylsilylamine into the reaction flask, and at the same time turn on the -10°C circulating chilled water in the reflux condenser, turn on the heating, and adjust the heating voltage to control the temperature rise Slowly distill off the diethylamine generated by the reaction. When the kettle temperature gradually rises to 155°C, the top temperature is kept at 125°C and basically unchanged, and the distilled fraction is detected by gas chromatography to be substantially free of diethylamine, the heating can be stopped, the temperature is lowered and cooled, and 2396g of the reacti...

Embodiment 2

[0040] The reaction device is equipped with an electric heating mantle, four-neck flask, electric stirring rod, thorn-shaped rectification column, reflux condenser, and receiving bottle. The bottom tube is opened with nitrogen gas, and the reaction device is purged with nitrogen bubbles to ensure that the device is dry.

[0041]Add 328g of phosphorous acid and 4312g of N-vinyldimethylsilylpiperidine to the reaction flask, and at the same time turn on the -10°C circulating chilled water in the reflux condenser, turn on the heating, adjust the heating voltage to control the heating rate, and slowly evaporate The reaction produces piperidine. When the kettle temperature gradually rises above 160°C, the top temperature remains basically constant above 135°C, and when the distilled fraction is substantially free of piperidine as detected by gas chromatography, the heating can be stopped, the temperature is lowered and cooled, and 3239g of the reaction solution is obtained by weighin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com