A kind of antifreeze cracking water supply pipe and its preparation method

A water supply pipe and anti-freeze cracking technology, which is applied in the field of anti-freeze crack water supply pipe formula and its preparation, can solve the problems of uneven dispersion of filler emulsions, and achieve the effect of poor thermal stability, good stability, and difficult precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

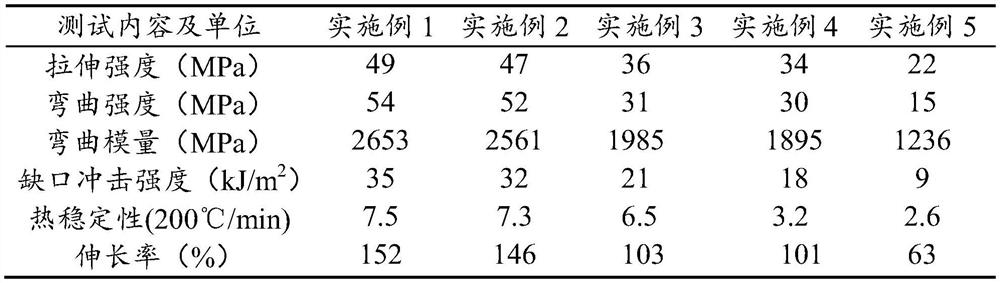

Examples

Embodiment 1

[0028] (1) Preparation of modified kaolin: mix ordinary kaolin with an appropriate amount of dilute hydrochloric acid, stir for 0.5-1 hour until the mixture is uniform, centrifuge after impregnating for 15-25 hours, wash with distilled water several times, wash with AgNO 3 Solution test until Cl free - ions, put it in an oven at 80-100°C and fully dry it for 10-15 hours, then put it in a muffle furnace at 350-400°C for 2-3 hours, cool to room temperature, and grind it into powder to obtain modified kaolin. The purpose of acidifying kaolin with dilute hydrochloric acid is to remove impurities in its internal channels, and can effectively make the surface of kaolin organic, so that the prepared filler emulsion can more effectively disperse between PVC masterbatches, and solve the problem of filler emulsion in PVC masterbatch. The problem of uneven dispersion between the materials makes the stability of each part of the material consistent;

[0029] (2) Preparation of filler emu...

Embodiment 2

[0033](1) Preparation of modified kaolin: mix ordinary kaolin with an appropriate amount of dilute hydrochloric acid, stir for 0.5-1 hour until the mixture is uniform, centrifuge after impregnating for 15-25 hours, wash with distilled water several times, wash with AgNO 3 Solution test until Cl free - ions, put it in an oven at 80-100°C and fully dry it for 10-15 hours, then put it in a muffle furnace at 350-400°C for 2-3 hours, cool to room temperature, and grind it into powder to obtain modified kaolin. The purpose of acidifying kaolin with dilute hydrochloric acid is to remove impurities in its internal channels, and can effectively make the surface of kaolin organic, so that the prepared filler emulsion can more effectively disperse between PVC masterbatches, and solve the problem of filler emulsion in PVC masterbatch. The problem of uneven dispersion between the materials makes the stability of each part of the material consistent;

[0034] (2) Preparation of filler emul...

Embodiment 3

[0038] (1) Preparation of filler emulsion: Add 40 parts by weight of ordinary kaolin, 10 parts by weight of ammonium sulfate and 10 parts by weight of polybutyl acrylate to 40 parts by weight of deionized water in sequence, stir at room temperature for 1 to 2 hours until uniformly mixed, and obtain filler emulsion;

[0039] (2) Preparation of composite stabilizer: put 30 parts by weight of zinc carbonate and 20 parts by weight of deionized water into a flask condensed and refluxed, heat in a water bath at 80-90°C for 1-2 hours to reflux, and add 30 parts by weight to the solution. Parts by weight of dibenzoylmethane, continue to reflux in a water bath at 80 to 90°C for 2 to 3 hours, then centrifuge, remove the upper filtrate, and obtain crystalline organic complex zinc; combine organic complex zinc, 20 weight parts of calcium stearate and 25 weight parts Mix 100% deionized water into a beaker, stir in a water bath at 60-70°C for 2-3 hours until fully mixed, centrifuge and put ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com