Method for continuously esterifying free fatty acids in crude rice bran oil and removing water from products

A technology of free fatty acid and crude rice bran oil, applied in the direction of fatty acid esterification, fat oil/fat refining, fat production, etc., can solve the problems of easy inactivation, poor stability, expensive free enzymes, etc., and achieves improved enzymatic hydrolysis efficiency, Reduced production cost, effect of wide pH range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

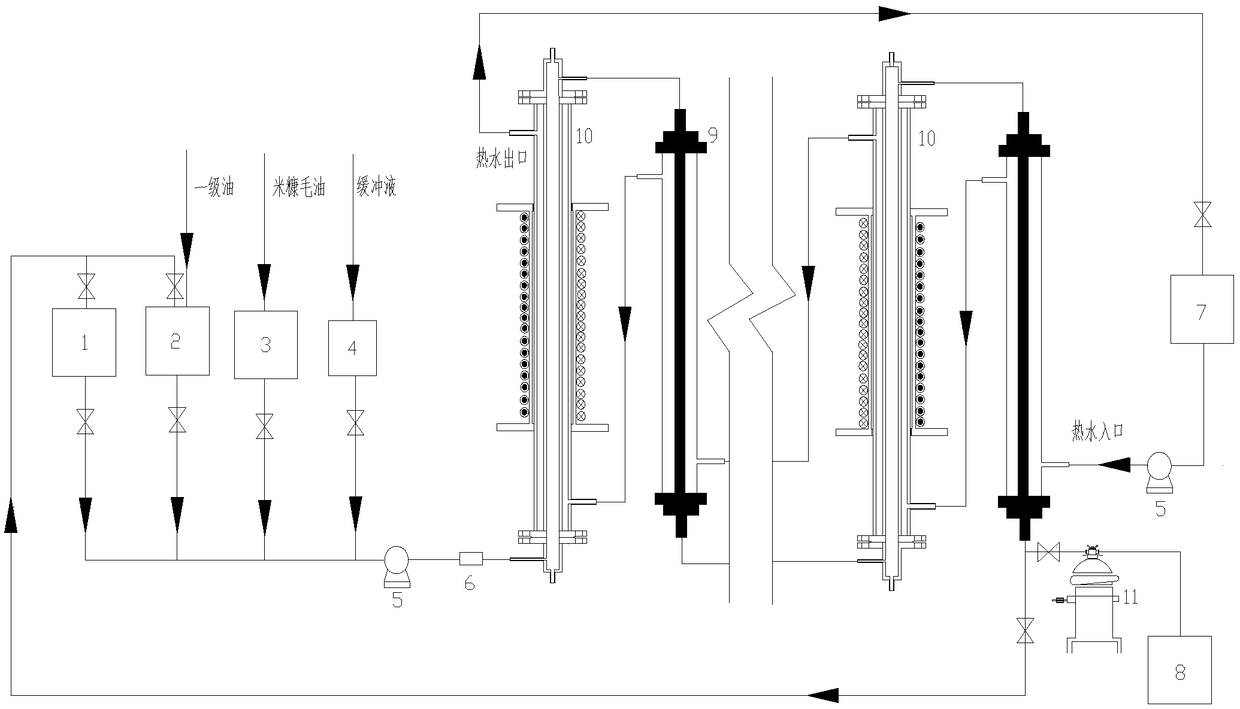

specific Embodiment approach 1

[0008] Specific implementation mode one: open the DC power supply of the magnetic fluidized bed, the hot water tank circulation system, add magnetase and phytosterol from the port on the magnetic fluidized bed, open the valve under the clean oil tank, adjust the system operating parameters, and make the magnetase in Fluidized state is reached in the magnetic fluidized bed. When the primary rice bran oil returns to the net oil tank, close the lower valve of the net oil tank, open the valves of the crude oil tank and the buffer tank, and adjust the pH value of the buffer in the buffer tank to 7.0, then the crude rice bran oil and buffer solution are transported to the first-stage liquid-solid two-phase magnetic fluidized bed reactor at a speed of 0.003m / s, and the external magnetic field strength is 0.024T, and the crude rice bran oil is heated to 60-95°C At this time, the addition amount of nano-magnetic immobilized lipase TIL in the first-level liquid-solid two-phase magnetic f...

specific Embodiment approach 2

[0009] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the crude rice bran oil is heated to 70-90° C., and other steps are the same as Embodiment 1.

specific Embodiment approach 3

[0010] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the amount of nano-magnetic immobilized lipase TIL is 2%-4%, and other steps are the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com