Medium-low temperature solar spectrum selective absorption coating and preparation method thereof

An absorption coating, solar spectrum technology, applied in coating, metal material coating process, ion implantation plating, etc., can solve the problem of low performance, and achieve the effect of improving absorption rate, increasing production capacity, and reducing reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

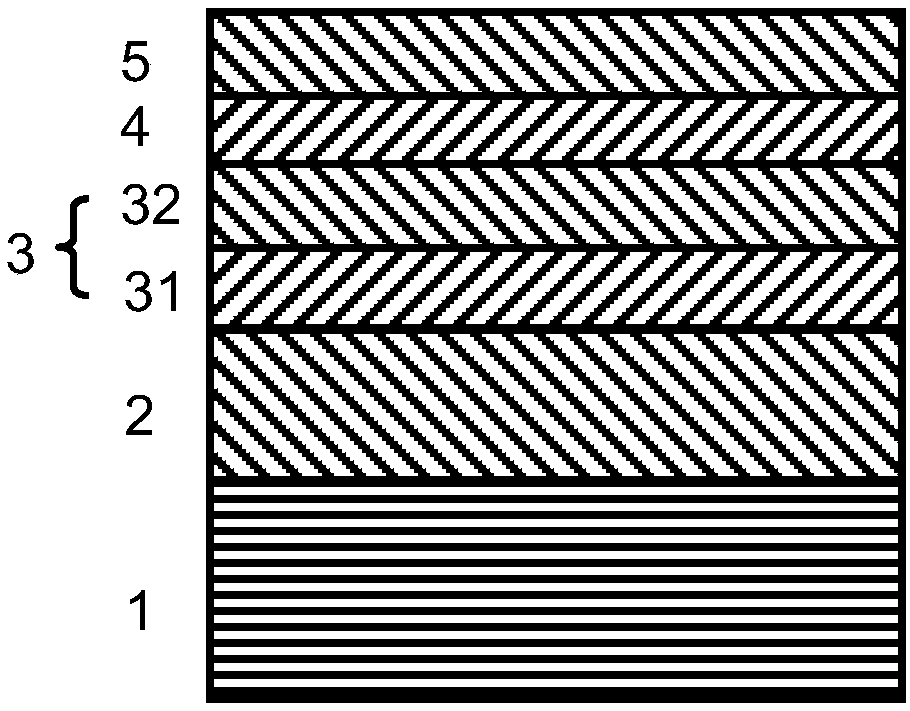

[0040] For the preparation of the substrate, a polished metal plate or glass plate is selected, and after mechanical cleaning, radio frequency argon ion cleaning is performed to remove the surface contamination layer and oxide layer, and to improve the surface activity of the substrate.

[0041] For the preparation of the infrared reflection layer, a metal infrared reflection layer is prepared on the surface of the above-mentioned base layer by (pulse) DC magnetron sputtering, and the selected target material can be metal aluminum (purity above 99.7%).

[0042] The preparation of the absorbing layer is to prepare the absorbing layer on the above-mentioned infrared reflective layer by (pulse) direct current magnetron sputtering method, and the selected target material is metal Cr (purity above 99.7%).

[0043] The preparation of the transition layer is to prepare the transition layer on the above-mentioned absorbing layer by (pulse) DC reactive magnetron sputtering, and the sele...

Embodiment

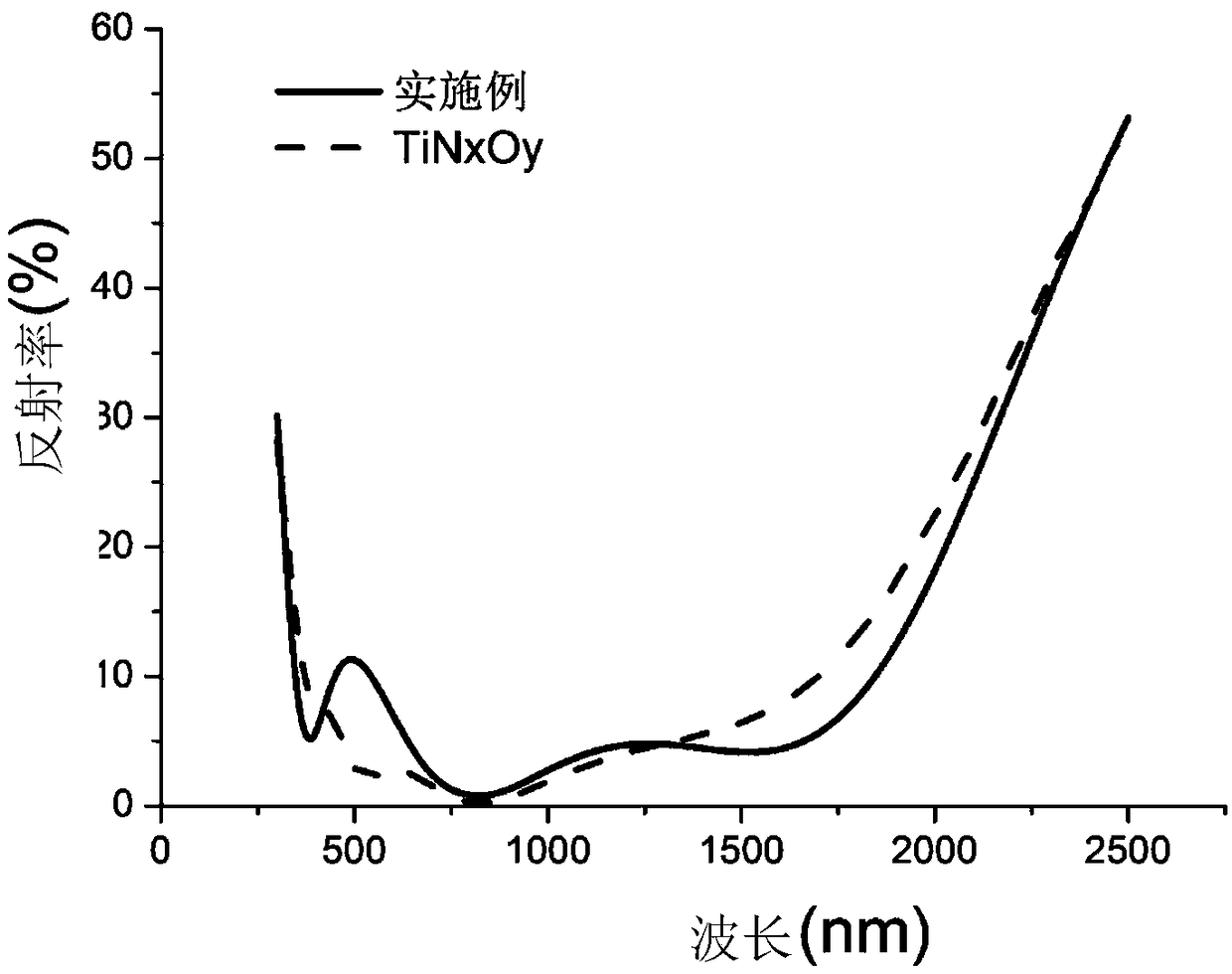

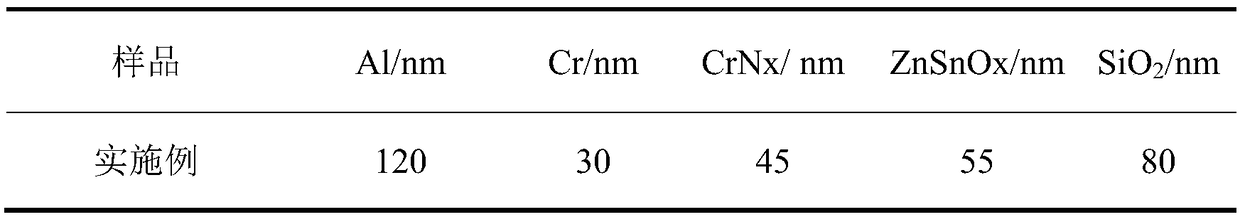

[0046] Table 1 shows the process-controlled thickness of each single-layer film in an embodiment of a double-absorbing layer-transition layer spectrally selective absorbing coating prepared by magnetron sputtering.

[0047] Table 1

[0048]

[0049] Carry out the preparation of embodiment according to above-mentioned preparation method, concrete operation steps are as follows:

[0050] 1) Cleaning of the glass substrate: Firstly, the glass substrate is initially cleaned with a neutral detergent; then, the surface of the glass substrate is bombarded by a radio frequency ion source in the film feeding chamber of the coating equipment for secondary cleaning, and the process parameters are set as follows: radio frequency The sputtering power of the power supply is 200w, the flow rate of the working gas Ar (purity 99.99%) is 45sccm, and the working pressure is 9×10 -2 mTorr, the sputtering time is 300s.

[0051] 2) The glass substrate is transported into the sputtering chamber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com