Slurry for 3D printing, 3D structure as well as preparation method and application thereof

A 3D printing and structure technology, applied in prosthesis, medical science, additive processing, etc., can solve the problems of insufficient stability and lack of biological activity of the scaffold, and achieve the goal of improving biological inertness, promoting cell activity and function, and improving structure. The effect of block phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

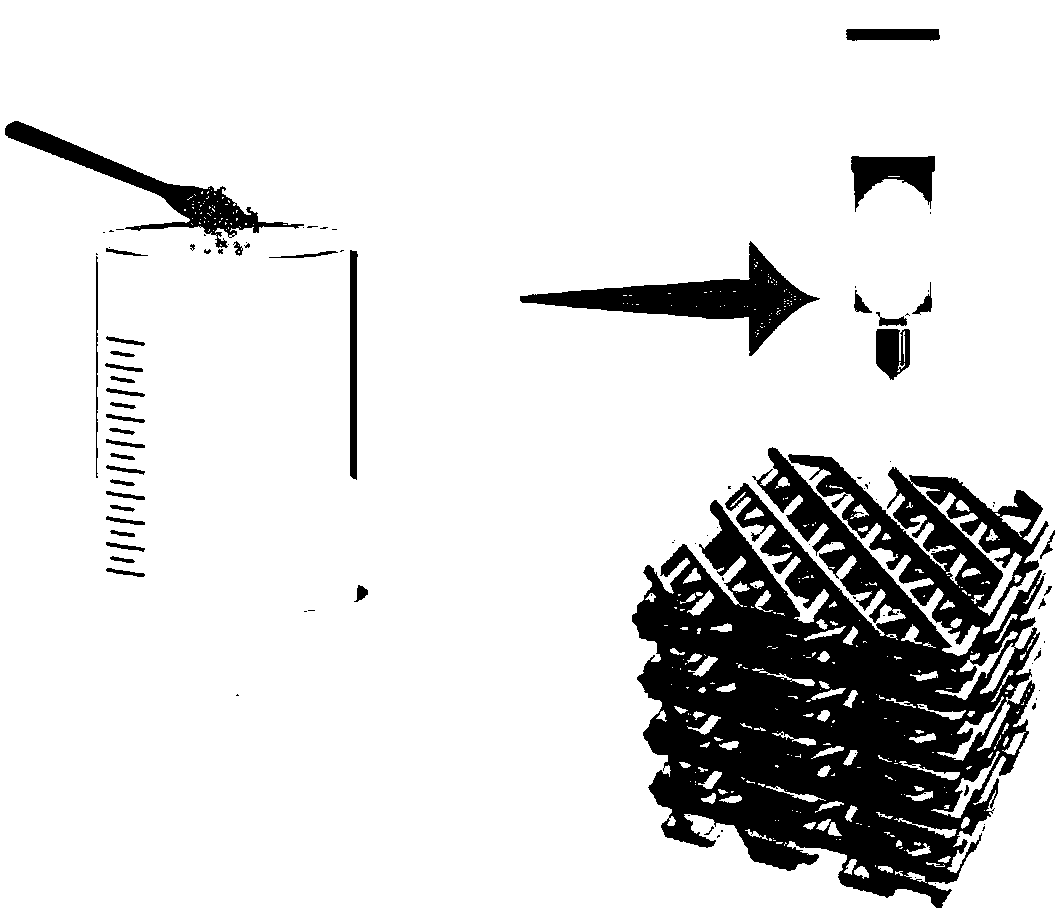

[0080] According to a second aspect of the present invention, a method for preparing a slurry for 3D printing is provided, comprising the following steps:

[0081] Mix alginate, polylysine and water evenly to obtain a slurry for 3D printing.

[0082] The preparation method of the slurry is simple and easy to obtain.

[0083] Preferably, the method for preparing the slurry for 3D printing includes the following steps: adding alginate into the solution of polylysine and water, and mixing evenly to obtain the slurry.

[0084] Specifically, the method includes the following steps: dissolving polylysine in a formula amount in water and mixing uniformly; adding alginate into the polylysine aqueous solution and mixing uniformly to obtain a 3D printing slurry.

[0085] Preferably, the solution of polylysine and water also includes effective biological ingredients.

[0086] Effective biological ingredients include one or more of nutrients, extracellular matrix, growth factors, cells ...

Embodiment 1

[0136] Example 1 Preparation of sodium alginate / polylysine bioink and its three-dimensional bioprinted bone model

[0137] A preparation method of sodium alginate / polylysine bioink and three-dimensional bioprinted bone model thereof, comprising the following steps:

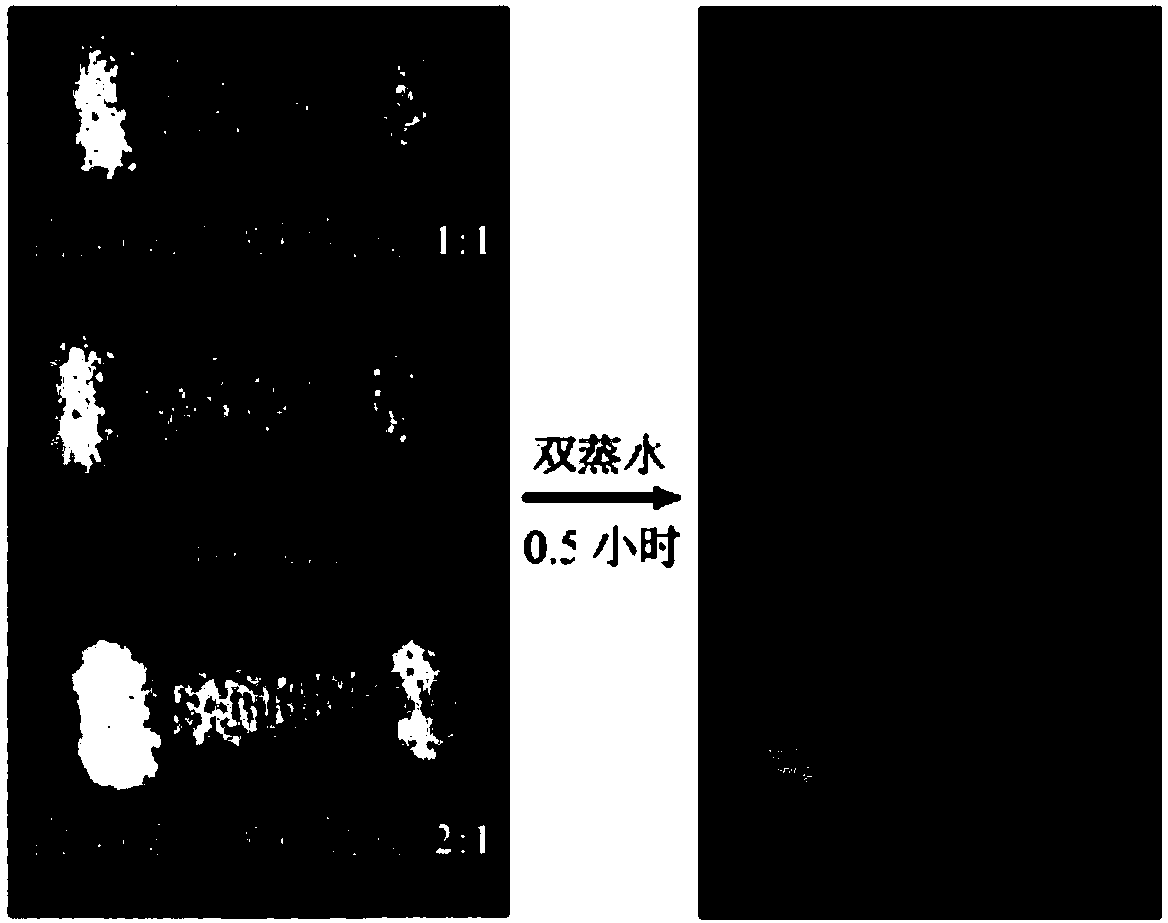

[0138] (1) Dissolve 2.924g polylysine in 10mL double-distilled water and stir evenly, weigh 4g sodium alginate and add it to the polylysine solution and stir until uniform to obtain the carboxyl group of sodium alginate and polylysine The molar ratio of amino groups is sodium alginate / polylysine bioink of 1:1;

[0139] (2) Put the bio-ink into the printing barrel, and use the three-dimensional bio-printer to print the bone model, the printing pressure is 600kPa, and the printing speed is 10mm / s.

Embodiment 2

[0141] The difference between this example and Example 1 is that the molar ratio of the carboxyl group of sodium alginate to the amino group of polylysine is 2:1.

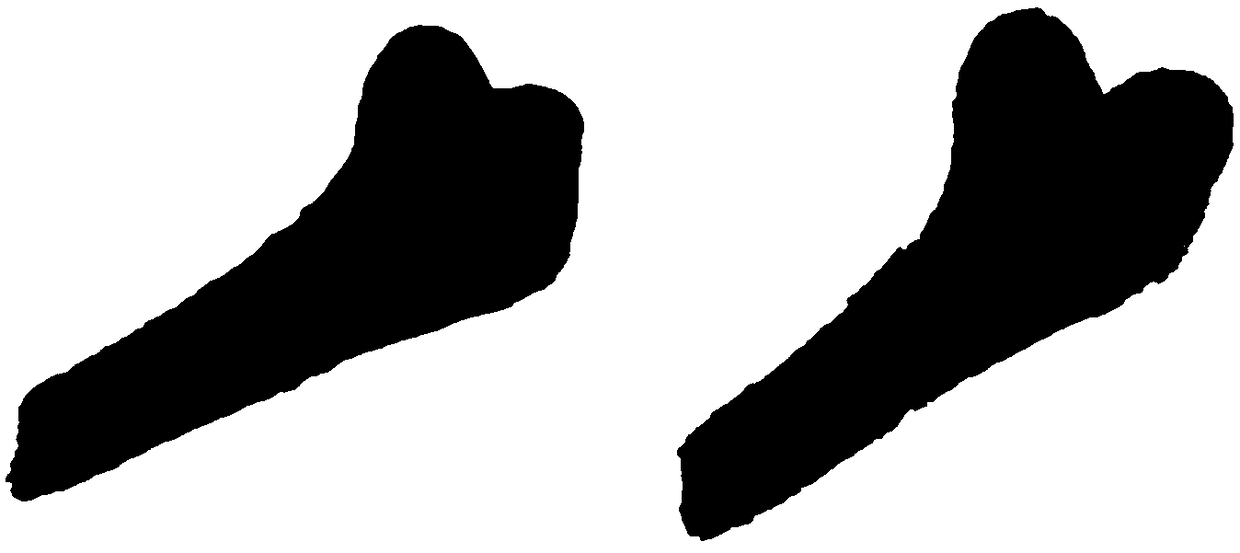

[0142] figure 2 For the bone model photo that embodiment 1 and embodiment 2 slurry print out, figure 2 It can be seen that the sodium alginate / polylysine bioink has self-supporting ability, can realize the printing of complex models, and has good formability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap