In-situ ecological remediation method for phosphate tailings

A technology for ecological restoration and phosphorus tailings, which is applied in the field of in-situ ecological restoration of phosphorus tailings and the treatment of phosphorus tailings to achieve the effect of solving governance problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

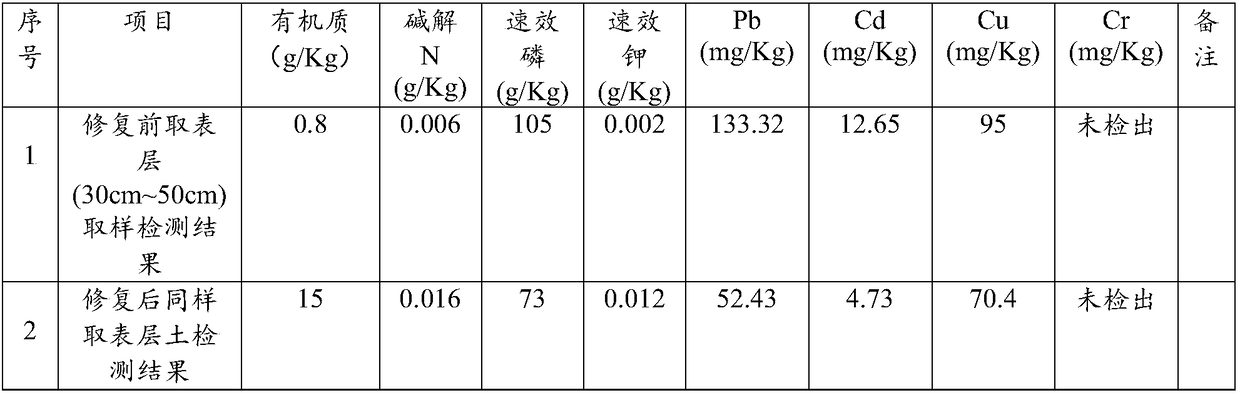

Examples

Embodiment 1

[0037] The preparation of embodiment 1 phosphorus tailings control special microbial preparation

[0038] 1. Raw materials

[0039] (1) Preparation of complex microbial flora

[0040] Microbial strains 100 ml. in:

[0041] Compound yeast strains (the number of effective viable bacteria ≥ 300 million / ml) accounted for 30%,

[0042] Composite functional strains (the number of effective viable bacteria ≥ 300 million / ml) accounted for 70%,

[0043] The compound yeast strain consists of Saccharomyces cerevisiae for beer brewing, Saccharomyces cerevisiae for sake brewing, wine yeast (Saccharomyces uvarum) and Saccharomyces cerevisiae for bread production, combining the above Four kinds of bacteria were compounded in equal amounts; wherein, the Saccharomyces cerevisiae used for brewing beer was purchased from China Industrial Microorganism Culture Collection and Management Center, and its commodity number was CICC31105; the Saccharomyces cerevisiae used for brewing sake was purch...

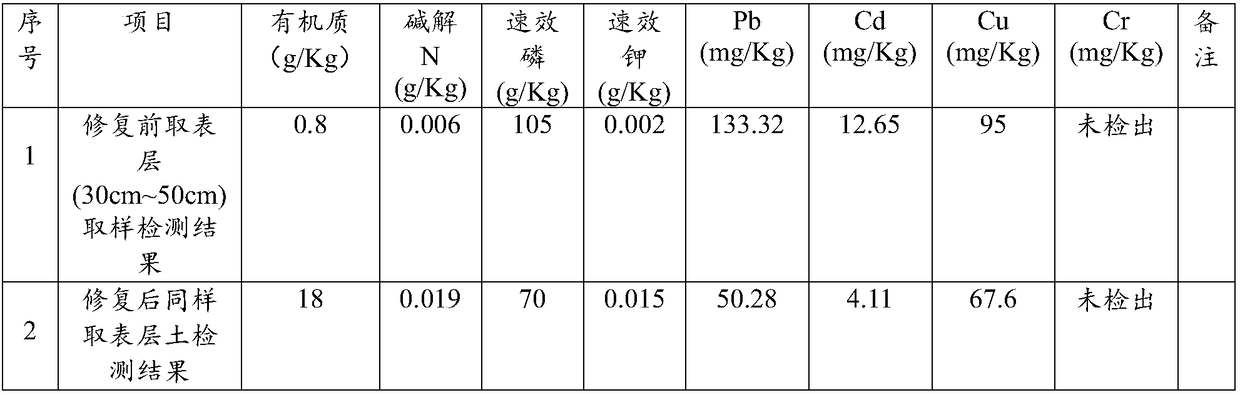

Embodiment 2

[0052] The preparation of embodiment 2 phosphorus tailings control special microbial preparation

[0053] 1. Raw materials

[0054] (1) Preparation of complex microbial flora

[0055] Microbial strains 100 ml. in:

[0056] Compound yeast strains (the number of effective viable bacteria ≥ 300 million / ml) accounted for 60%,

[0057] Composite functional strains (the number of effective viable bacteria ≥ 300 million / ml) accounted for 40%,

[0058] The compound yeast strain consists of Saccharomyces cerevisiae for beer brewing, Saccharomyces cerevisiae for sake brewing, wine yeast (Saccharomyces uvarum) and Saccharomyces cerevisiae for bread production, combining the above Four kinds were compounded in equal amounts; the Saccharomyces cerevisiae used for brewing beer was purchased from China Industrial Microorganism Culture Collection and Management Center, and its product number was CICC31105; the Saccharomyces cerevisiae used for brewing sake was purchased from China Industr...

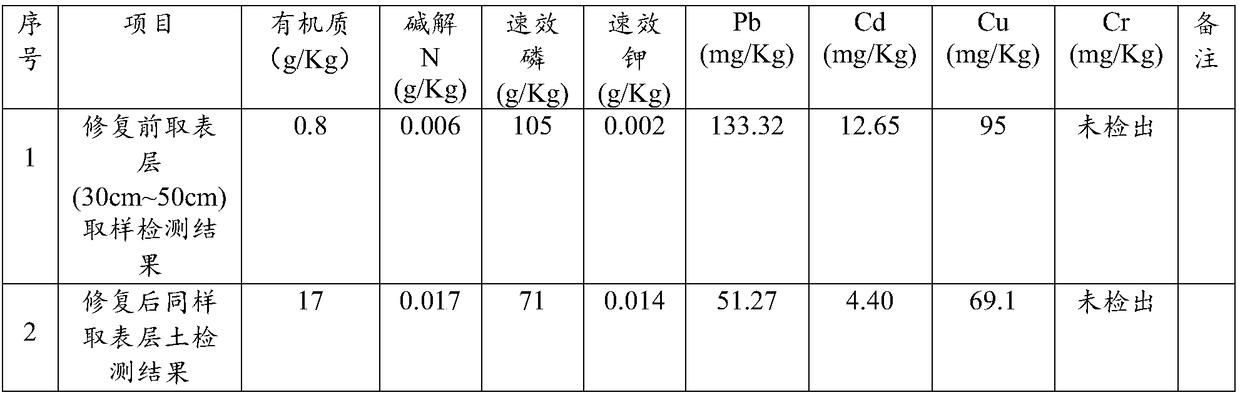

Embodiment 3

[0067] The preparation of embodiment 3 phosphorus tailings control special microbial preparation

[0068] 1. Raw materials

[0069] (1) Preparation of complex microbial flora

[0070] Microbial strains 100 ml. in:

[0071] Compound yeast strains (the number of effective viable bacteria ≥ 300 million / ml) accounted for 45%,

[0072] Composite functional strains (the number of effective viable bacteria ≥ 300 million / ml) accounted for 55%,

[0073] The compound yeast strain is composed of Saccharomyces cerevisiae for brewing beer, Saccharomyces cerevisiae for sake brewing, Saccharomyces uvarum for wine and Saccharomyces cerevisiae for bread production, combining the above four The same amount of bacteria was compounded; the Saccharomyces cerevisiae used for brewing beer was purchased from China Industrial Microbiology Culture Collection Management Center, and its commodity number was CICC31105; the Saccharomyces cerevisiae used for brewing sake was purchased from China Industr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com