In-situ leaching uranium mining mine wastewater deodorization method

A technology for mining wastewater and in-situ leaching of uranium, which is applied in mining wastewater treatment, chemical instruments and methods, water aeration, etc. Solve the effect of producing bad odor and high social value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

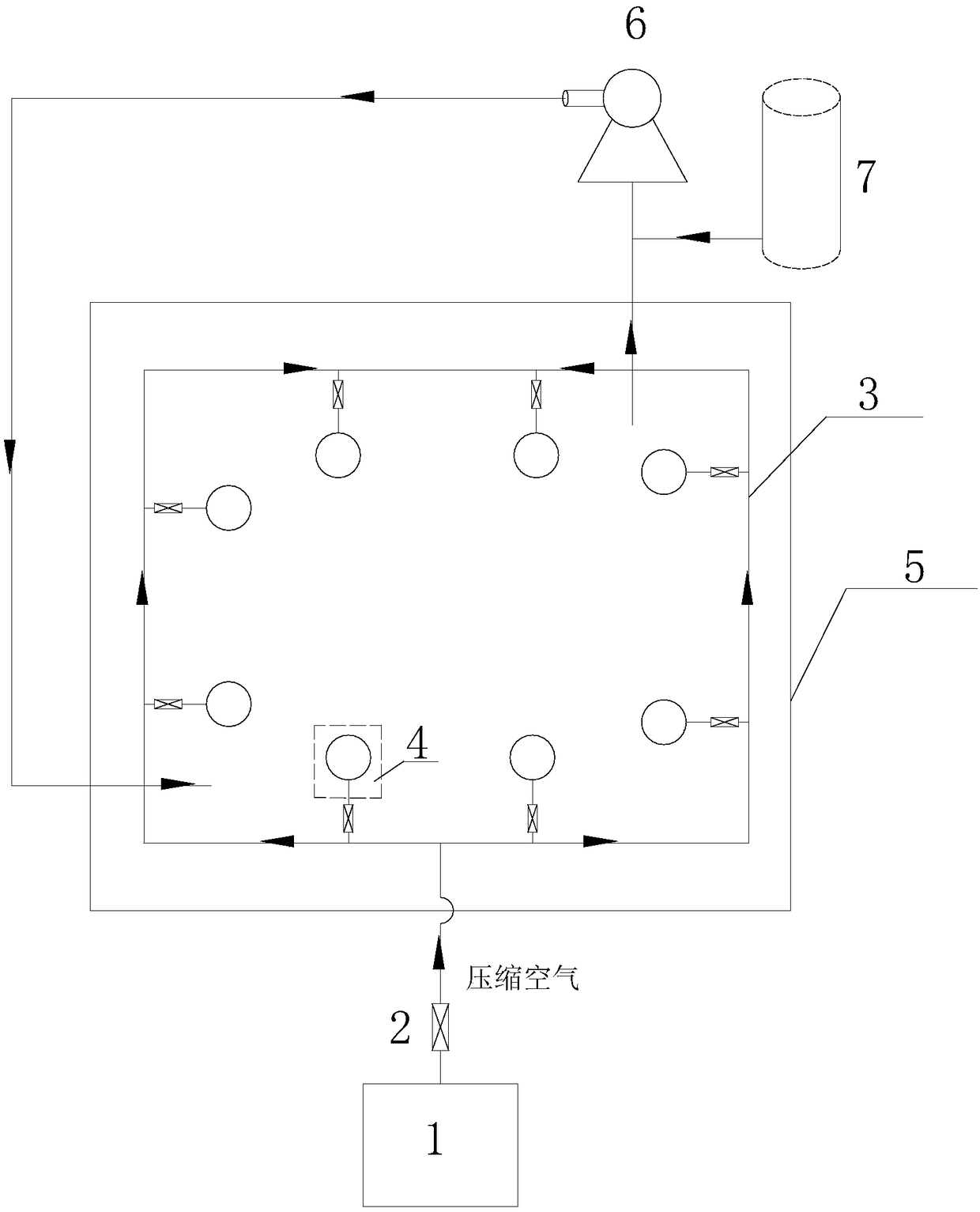

[0029] Such as figure 1 A deodorization method for in-situ leaching uranium mining wastewater is shown, which is suitable for CO 2 +O 2 In-situ leaching of uranium mines, including the following steps:

[0030] (a) Install aeration device 4

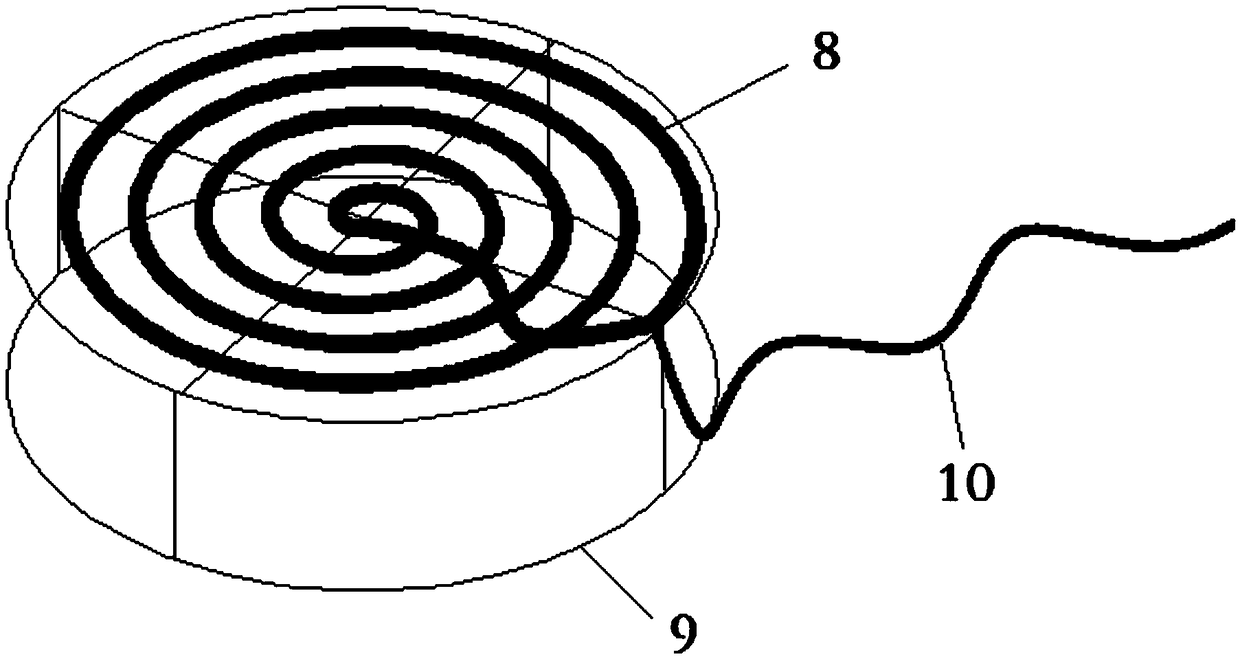

[0031] In the evaporation pool 5, a circle of aeration device 4 is arranged around the inner edge of the evaporation pool 5. The aeration device 4 is 2-5m away from the inner edge of the evaporation pool 5, which is convenient for installation and recycling. Such as figure 2 As shown, the aeration device 4 includes an aeration tube 8 , a bracket 9 and a reticulated tube 10 . The aeration tube 8 is spirally fixed on the bracket 9, and the height of the bracket 9 is 20 to 50 cm, so that the aeration tube 8 is kept at a certain distance from the sludge at the bottom of the evaporation pool 5 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com