System and method for continuous and constant blowdown energy collection of boiler

A boiler and fixed-discharge technology, applied in chemical instruments and methods, separation methods, boiler cleaning devices, etc., can solve the problems of sewage cooling and limited thermal energy, and achieve the effects of environmental protection, noise pollution, efficient recovery, and noise elimination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific technical solutions of the present invention are further described below, so that those skilled in the art can further understand the present invention, without limiting their rights.

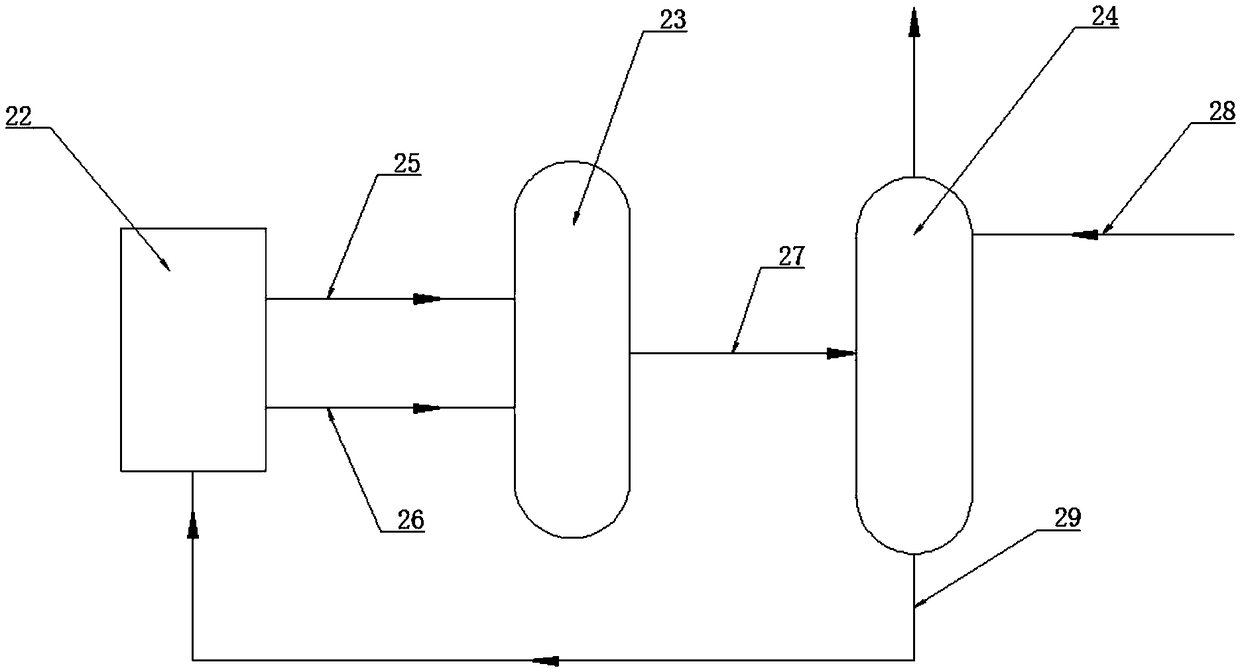

[0039] refer to figure 2 , a boiler with fixed discharge energy collection system, comprising:

[0040] Expansion container 23, expansion container 23 is connected with the continuous discharge outlet of boiler 22 by continuous row pipeline 25, is connected with the fixed discharge outlet of boiler 22 by fixed row pipeline 26;

[0041] An energy receiver 24, the energy receiver 24 is connected with the steam outlet of the expander 23 through a steam pipeline 27;

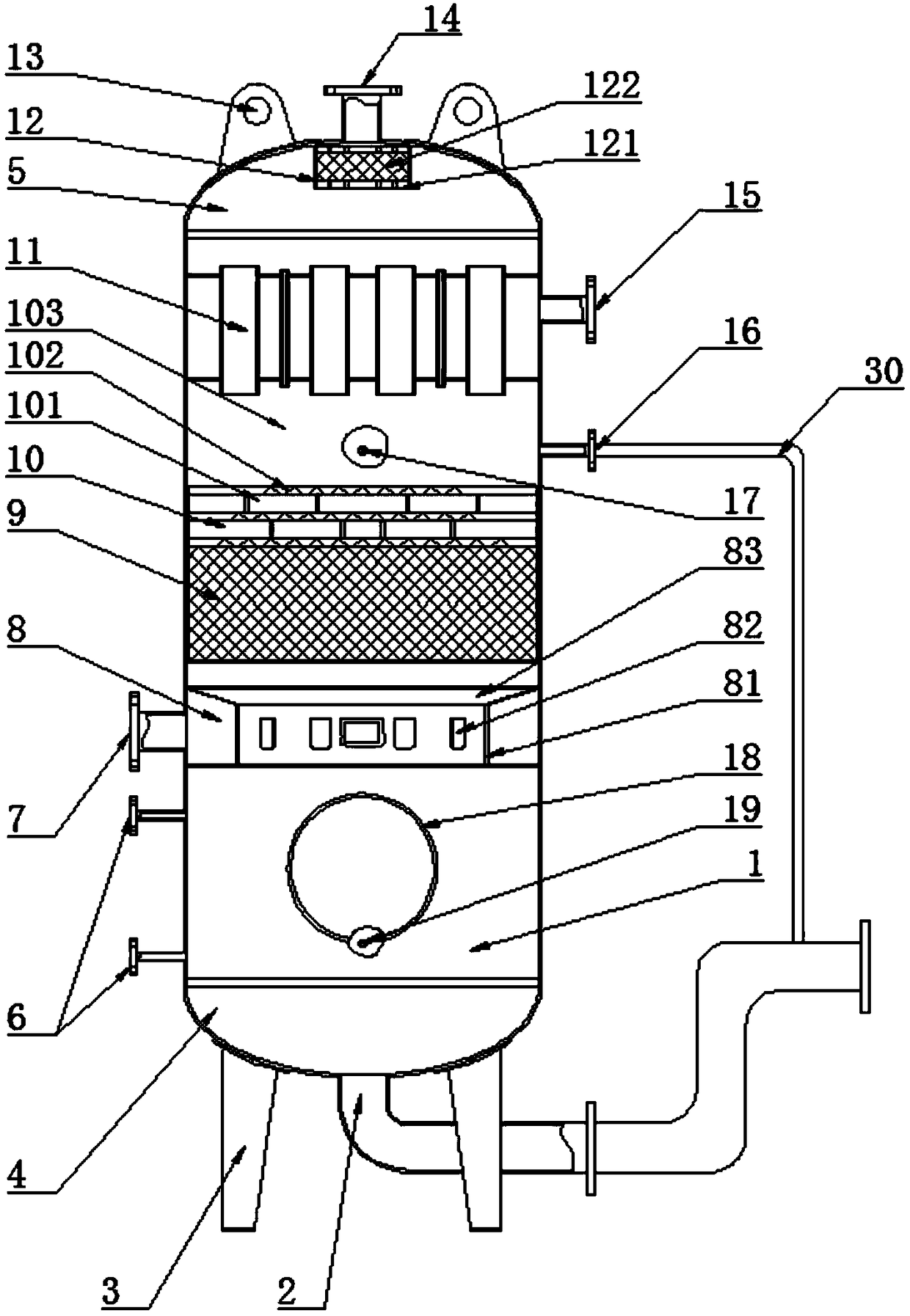

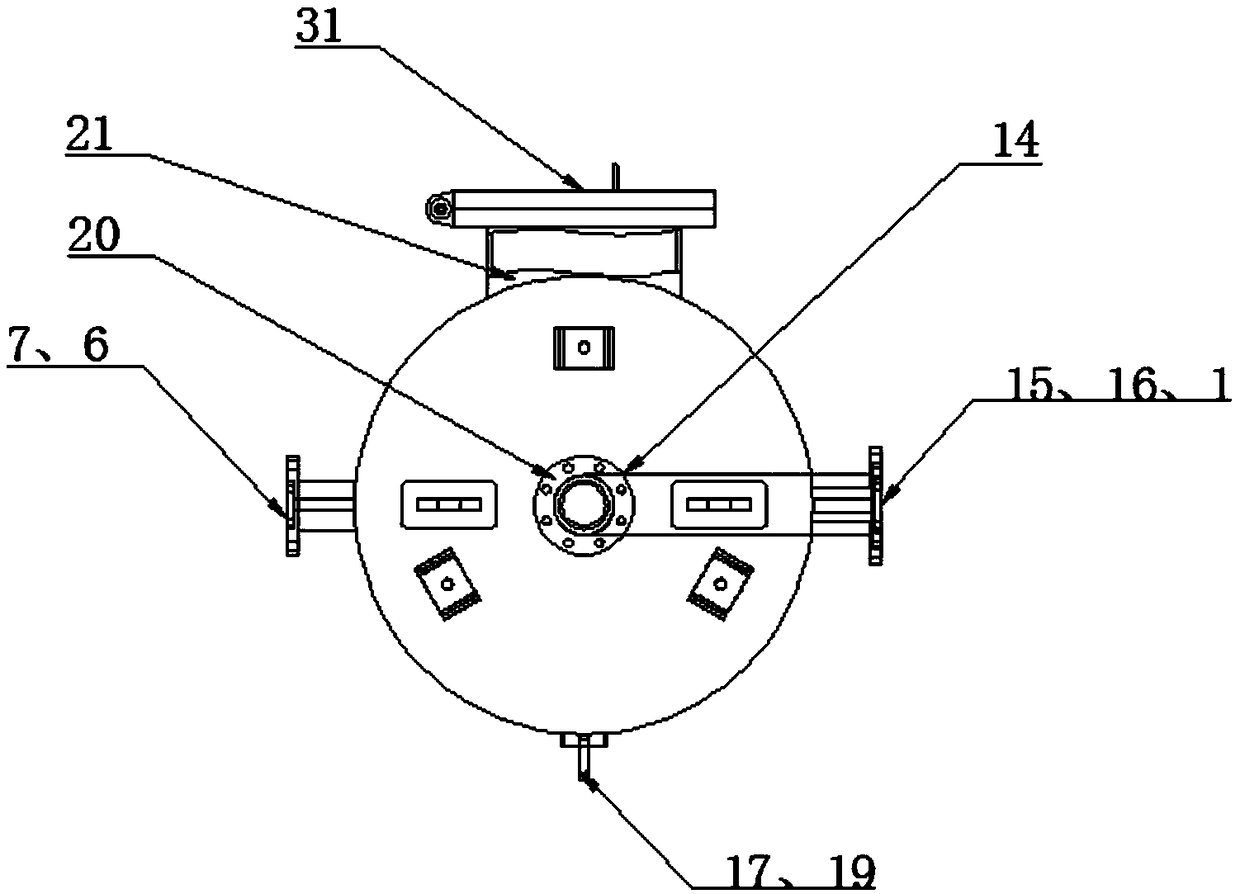

[0042] refer to figure 1 , combined with image 3 , the energy receiver 24 is provided with a vertical cylinder 1, the upper and lower parts of the cylinder 1 are respectively provided with an upper seal 5 and a lower seal 4, and the upper seal 5 is provided with an oxygen outlet 14 , the lower head 4 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com