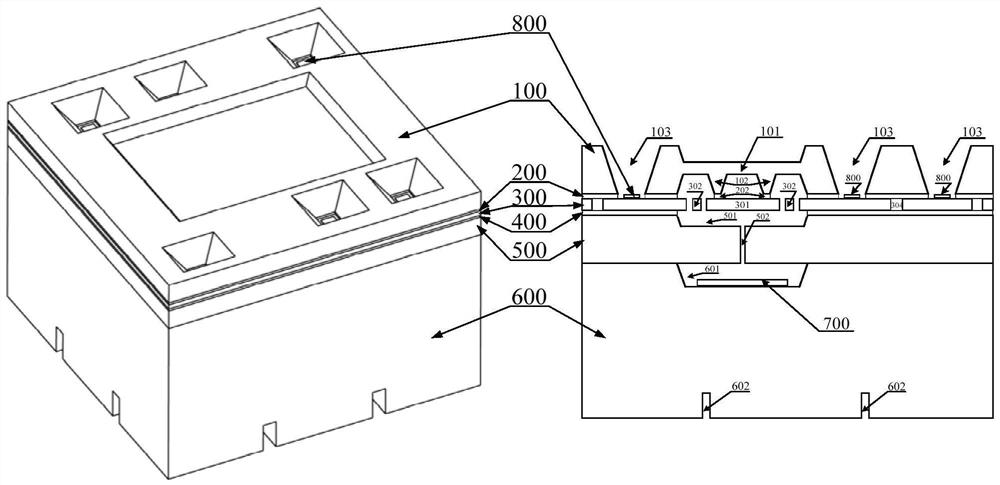

Mems resonant pressure sensor and manufacturing process based on si-si-si-glass wafer bonding technology

A si-si-si-, pressure sensor technology, applied in the field of sensitive chips of resonant pressure sensors, can solve the problems of long-term stability, reliability, manufacturing process difficulty, etc., to ensure high quality factors, reduce residual stress and heat Effect of stress and high real-time temperature compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

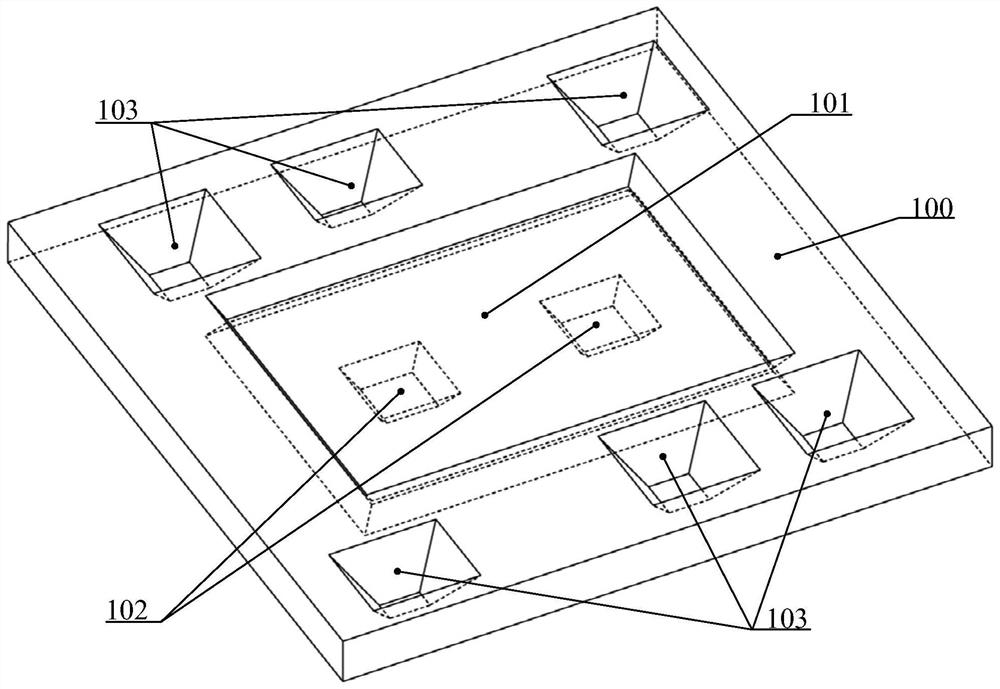

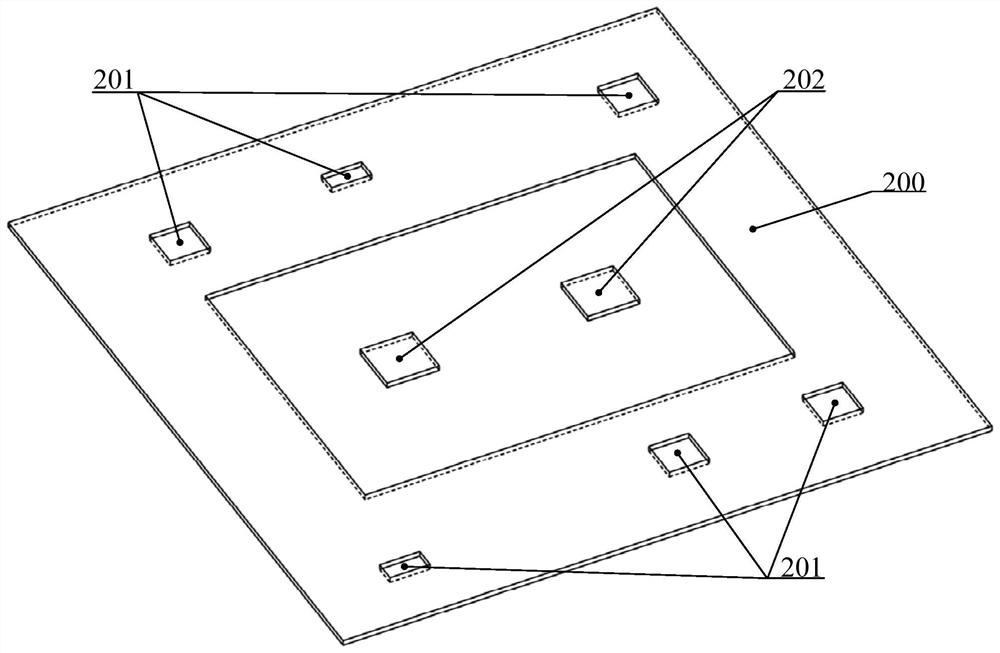

[0073]The Si pressure-sensitive layer 100 is made of ultra-low resistivity (2 The layer is fabricated based on an oxide layer below the Si pressure sensitive layer 100 with a thickness of 0.8 μm. The thickness of the Si resonator layer is 60 μm, the resistivity is ±0.2Ω·cm within a certain value in the range of 0.1Ω·cm to 5Ω·cm, (100) crystal orientation, and P-type silicon. Second SiO 2 The layer is fabricated based on an oxide layer above the Si pit substrate layer 500 with a thickness of 0.8 μm. The Si pit substrate layer is made of ultra-low resistivity (-6 ~3.5×10 -6 . The depth of the pit structure 601 is 50 μm, the depth of the topological stress isolation strip groove structure 602 is 0.8 mm, the topological form is a well-shaped grid, and the getter film 700 is a Ti metal film with a thickness of 500 nm.

[0074] Such as Figure 8 ~ Figure 18 It is the MEMS manufacturing process step of the sensor of the present invention.

[0075] (1) Figure 8 Shown is a schem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com