1-methyl cyclohexyl methacrylate preparation method

A technology of methylcyclohexyl methacrylate and methylcyclohexanol, which is applied in the field of organic chemical synthesis, can solve problems such as the inability to directly obtain the preparation method of cyclohexyl methacrylate, and achieve increased yield and reduced impurity content Effect

Active Publication Date: 2019-03-19

上海博栋化学科技有限公司

View PDF6 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Can not directly obtain the preparation method of other 1-alkyl substituted cyclohexyl methacrylate from this technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

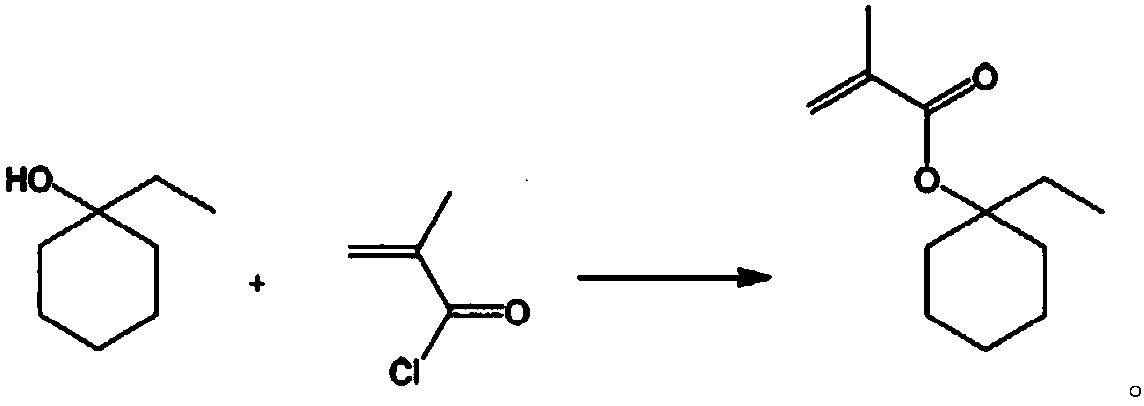

[0031] This embodiment relates to the synthesis of 1-methylcyclohexyl methacrylate, and its synthetic route is as follows:

[0032]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

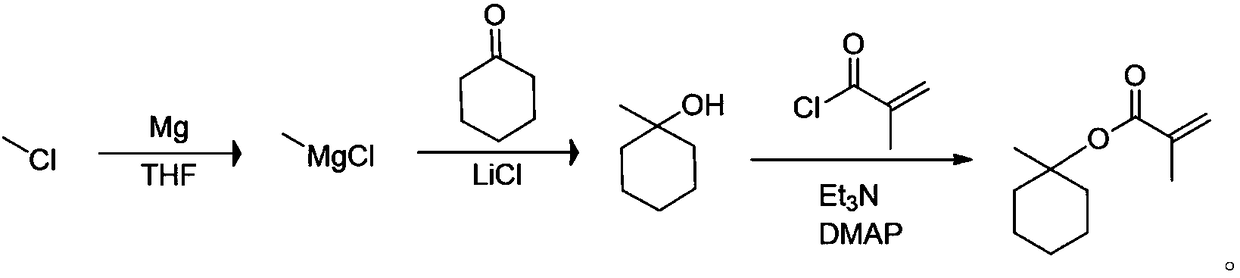

The invention relates to a 1-methyl cyclohexyl methacrylate preparation method which includes the steps: S1 enabling 1-methyl-cyclohexanol to react with methacryloyl chloride in organic solvents underprotection of inert gas and under the condition of presence of at least first catalysts, second catalysts and polymerization inhibitors to obtain reaction mixture containing 1-methyl cyclohexyl methacrylate; S2 washing first reaction mixture sequentially by water, acid solution, water and alkaline solution, and layering the mixture to obtain a fourth water phase and a fourth organic phase; S3 drying, concentrating and rectifying the fourth organic phase under vacuum, and collecting a main distillate fraction after temperature is stabilized about 68 DEG C for 5 minutes to obtain colorless transparent liquid 1-methyl cyclohexyl methacrylate. The preparation method has the advantages that linear chain alkylamine and aromatic amine serve as catalysts for catalyzing reaction of the 1-methyl-cyclohexanol and the methacryloyl chloride, product yield can be remarkably improved, and the impurity content of a product is reduced.

Description

technical field [0001] This application relates to the technical field of organic chemical synthesis. Specifically, the application relates to a preparation method of 1-methylcyclohexyl methacrylate. Background technique [0002] Polymethacrylate is the main resin of 193nm photoresist, and the main component of its film-forming resin is alicyclic polymer. The main chain of the acrylate photoresist film-forming resin is generally a polymer of methylene, and its main function is to provide the mechanical properties required for film formation and processing, while its imaging force, adhesion, developability and Most of the corrosion resistance is borne by the side chains. Therefore, the side chain design of the main resin is particularly critical. [0003] Due to the linear structure (low C / H ratio) of its main chain, it has poor dry etching resistance. In order to meet this requirement, when designing the film-forming resin of 193nm photoresist, it is usually adopted to in...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C07C67/14C07C69/54

CPCC07C29/40C07C67/14C07C2601/14C07C69/54C07C35/08

Inventor 傅志伟贺宝元潘新刚余文卿谷春燕蒋小惠

Owner 上海博栋化学科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com