Preparation method of xanthan gum/chitosan nanofiber membrane

A technology of chitosan nano and xanthan gum, which is applied in fiber treatment, filament/thread forming, textile and papermaking, etc., to achieve the effect of reducing adhesion performance, improving release persistence, and easy-to-understand preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

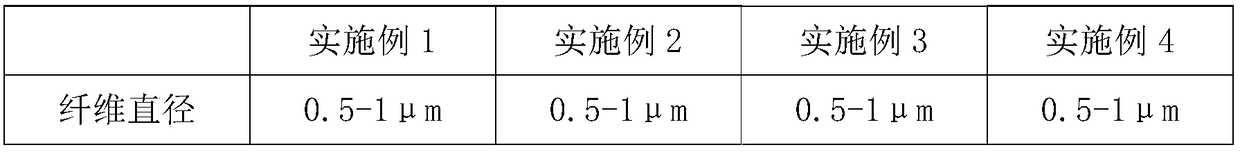

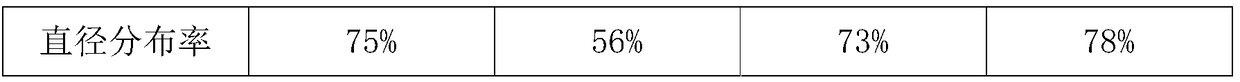

Embodiment 1

[0031] A preparation method of xanthan gum / chitosan nanofiber membrane includes the following steps:

[0032] (1) Preparation of electrospinning solution:

[0033] First, 1 g of xanthan gum (Mw=20 million) and 2 g (Mw=200,000) of chitosan were dissolved in 100 mL of formic acid solution, and then magnetically vigorously stirred at room temperature for 20 hours to obtain a viscoelastic gel solution. Then 1g of curcumin was added to the above gel solution, mixed and stirred for 20 minutes to dissolve to obtain a homogeneous solution. The mixed solution was ultrasonically treated with a 1000W ultrasonic instrument at 40% intensity for 10 minutes to prepare a xanthan gum-chitosan-curcumin nanocomposite solution.

[0034] (2) Manufacturing of xanthan gum / chitosan nanofiber membrane:

[0035] The solution for preparing the composite material was injected into a 10 mL plastic syringe with a 21-G stainless steel needle and connected to the syringe pump. The spinning voltage was 20KV, the ad...

Embodiment 2

[0038] A preparation method of xanthan gum / chitosan nanofiber membrane includes the following steps:

[0039] (1) Preparation of electrospinning solution:

[0040] First, 0.5g of xanthan gum (Mw=10 million) and 4g (Mw=400,000) of chitosan were dissolved in 100mL of a mixed solution of formic acid and phosphoric acid, and then magnetically stirred vigorously at room temperature for 40 hours to obtain a viscoelastic gel solution . Then 4 g of curcumin was added to the gel solution, mixed and stirred for 60 minutes to dissolve to obtain a homogeneous solution. The mixed solution was ultrasonically treated with a 1000W ultrasonic instrument at 40% intensity for 30 minutes to prepare a xanthan gum-chitosan-curcumin nanocomposite solution.

[0041] (2) Manufacturing of xanthan gum / chitosan nanofiber membrane:

[0042] The solution for preparing the composite material was injected into a 10 mL plastic syringe with a 21-G stainless steel needle and connected to the syringe pump. The spinni...

Embodiment 3

[0044] A preparation method of xanthan gum / chitosan nanofiber membrane includes the following steps:

[0045] (1) Preparation of electrospinning solution:

[0046] First, 0.8g xanthan gum (Mw=5 million) and 10g (Mw=500,000) chitosan were dissolved in 100mL of formic acid and phosphoric acid mixed solution, and then magnetically vigorously stirred at room temperature for 30 hours to obtain a viscoelastic gel solution . Then, 5 g of curcumin was added to the above gel solution, mixed and stirred for 10 minutes to dissolve to obtain a homogeneous solution. The mixed solution was ultrasonically treated with a 1000W ultrasonic instrument at 40% intensity for 5 minutes to prepare a xanthan gum-chitosan-curcumin nanocomposite solution.

[0047] (2) Manufacturing of xanthan gum / chitosan nanofiber membrane:

[0048] The solution for preparing the composite material was injected into a 10 mL plastic syringe with a 21-G stainless steel needle and connected to the syringe pump. The spinning vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com