Porcelain firing temperature control furnace

A technology for temperature-controlled furnaces and porcelain, which is applied to furnaces, charge materials, and furnace types. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

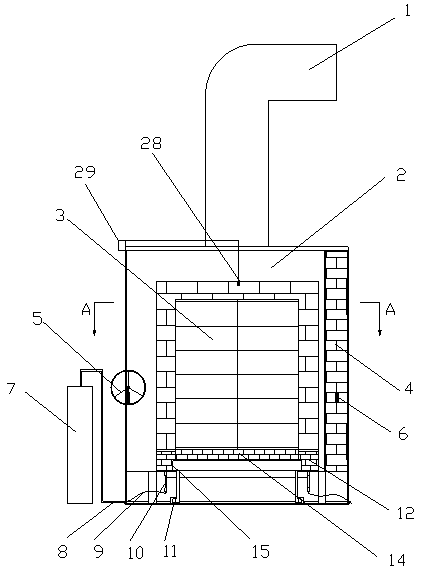

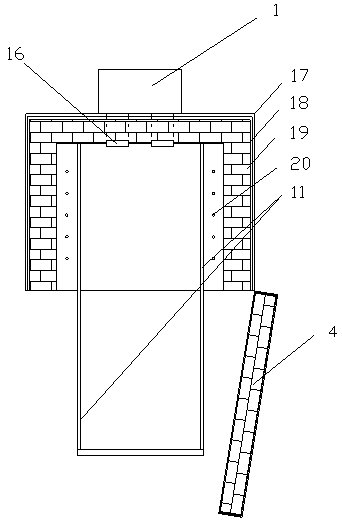

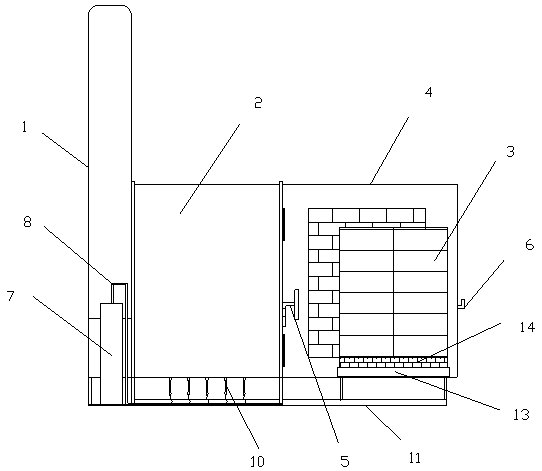

[0022] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

[0023] Such as Figure 1~5 As shown, a porcelain firing temperature control furnace includes a furnace body 2, a chimney 1, a movable rack mechanism and a gas mechanism. The chimney 1 is arranged on the back of the furnace body 2, and it passes through the flue and connected, and two flue openings 16 are formed on the inner side of the back of the furnace body. The furnace body 2 is a square structure raised by steel frame legs, its front end and lower end are open structures, and its front end An opening and closing door 4 is arranged on the top, and the furnace body 2 and the opening and closing door 4 are all three-layer structures, such as figure 2 Shown, their inner layer is refractory brick layer 19, and their outer layer is iron skin layer 17, is provided with refractory asbestos layer 18 between r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com