Barium stannate nano-tube gas-sensitive material with high gas sensitive selection on acetic acid gas

A gas-sensitive material, barium stannate technology, which is applied in the direction of analyzing materials, material resistance, and material analysis through electromagnetic means, can solve the problems of long-term consumption and high cost, and achieve the effect of high gas-sensing selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

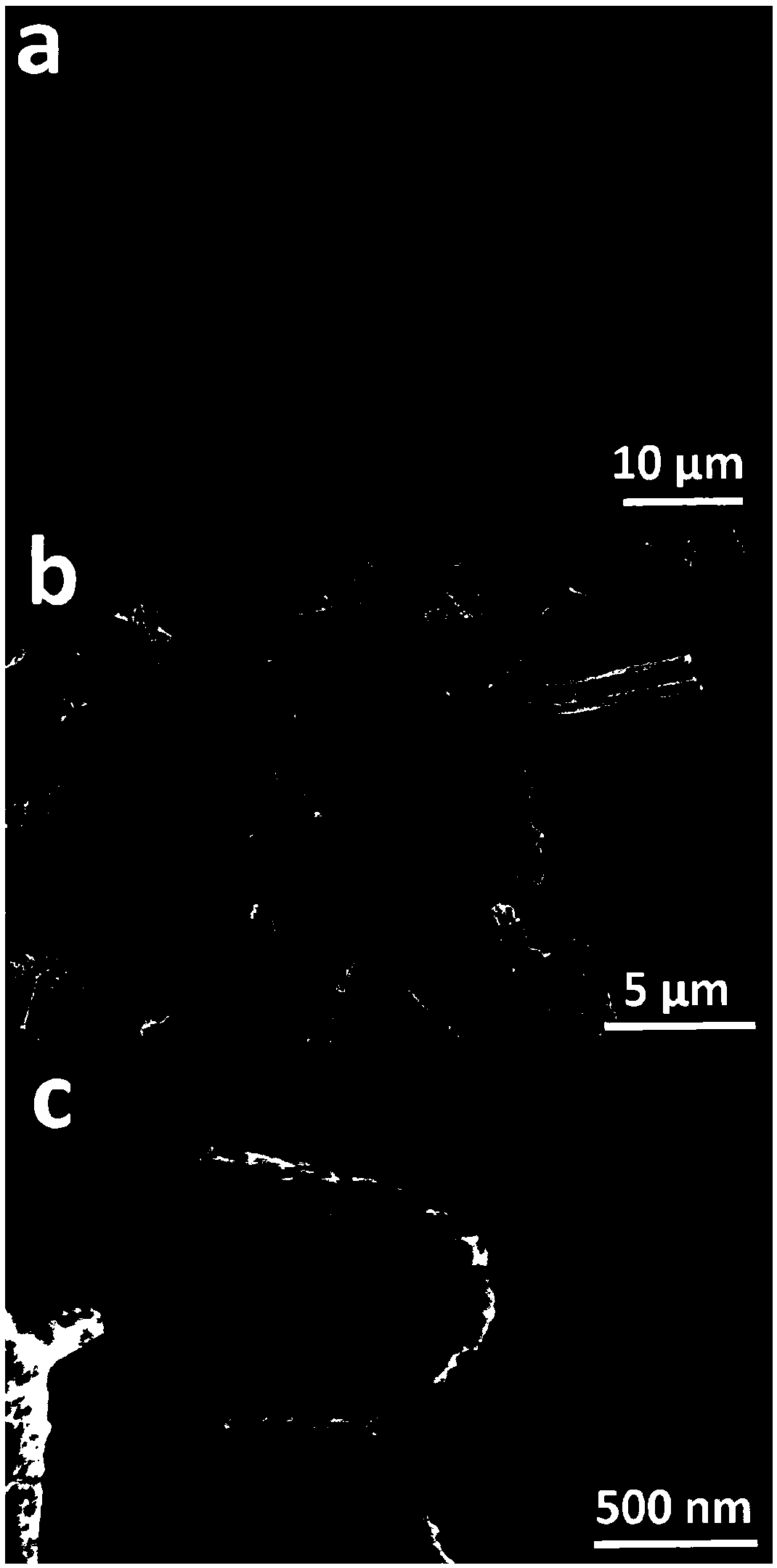

Image

Examples

Embodiment 1

[0014] 0.001 mole of Ba(NO 3 ) 2 and 0.001 molar SnCl 4 ·5H 2 O stirred and dissolved in dimethylformamide (DMF), added polyvinylpyrrolidone (PVP, molecular weight 130000), stirred and dissolved to obtain a solution for electrospinning, the PVP mass percentage in the solution was 15%, Ba(NO 3 ) 2 and SnCl 4 ·5H 2 The sum of O mass accounts for 15% of the solution mass. Add the solution into a medical syringe, connect the needle point and the collecting aluminum foil to a high-voltage power supply, the voltage is 17kV, the needle point is on the top, and the distance between the needle point and the collecting aluminum foil is 13 cm. Under the action of gravity and electric field, stannic acid is collected on the aluminum foil after 4 hours For the precursor of barium nanotubes, the precursor was dried in air at 200°C for 10 minutes, and then heat-treated in a muffle furnace for 2 hours at a temperature of 680°C and a heating rate of 1°C / min.

[0015] The material is mad...

Embodiment 2

[0017] 0.001 mole of Ba(NO 3 ) 2 and 0.001 molar SnCl 4 ·5H 2 O stirred and dissolved in dimethylformamide (DMF), added polyvinylpyrrolidone (PVP, molecular weight 130000), stirred and dissolved to obtain a solution for electrospinning, the PVP mass percentage in the solution was 15%, Ba(NO 3 ) 2 and SnCl 4 ·5H 2 The sum of O mass accounts for 15% of the solution mass. Add the solution into a medical syringe, connect the needle point and the collecting aluminum foil to a high-voltage power supply, the voltage is 18kV, the needle point is on the top, and the distance between the needle point and the collecting aluminum foil is 15 cm. Under the action of gravity and electric field, stannic acid is collected on the aluminum foil after 4 hours For the precursor of barium nanotubes, the precursor was dried in air at 200°C for 10 minutes, and then heat-treated in a muffle furnace for 2 hours at a temperature of 700°C and a heating rate of 1°C / min.

[0018] The material is mad...

Embodiment 3

[0020] 0.001 mole of Ba(NO 3 ) 2 and 0.001 molar SnCl 4 ·5H 2 O stirred and dissolved in dimethylformamide (DMF), added polyvinylpyrrolidone (PVP, molecular weight 130000), stirred and dissolved to obtain a solution for electrospinning, the PVP mass percentage in the solution was 15%, Ba(NO 3 ) 2 and SnCl 4 ·5H 2 The sum of O mass accounts for 15% of the solution mass. Add the solution into a medical syringe, connect the needle point and the collecting aluminum foil to a high-voltage power supply, the voltage is 18kV, the needle point is on the top, and the distance between the needle point and the collecting aluminum foil is 15 cm. Under the action of gravity and electric field, stannic acid is collected on the aluminum foil after 4 hours For the precursor of barium nanotubes, the precursor was dried in air at 200°C for 10 minutes, and then heat-treated in a muffle furnace for 2 hours at a temperature of 720°C and a heating rate of 1°C / min.

[0021] The material is mad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com