Processing and manufacturing method of ornamental gourd silk

A production method and technology for gourd, applied in the field of food processing, can solve the problems of affecting the crisp taste of gourd silk, soft and soft cotton of gourd silk, and destroying the nutritional components of gourd silk, so as to maintain freshness and color, disinfection effect, The effect of prolonging the storage and preservation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

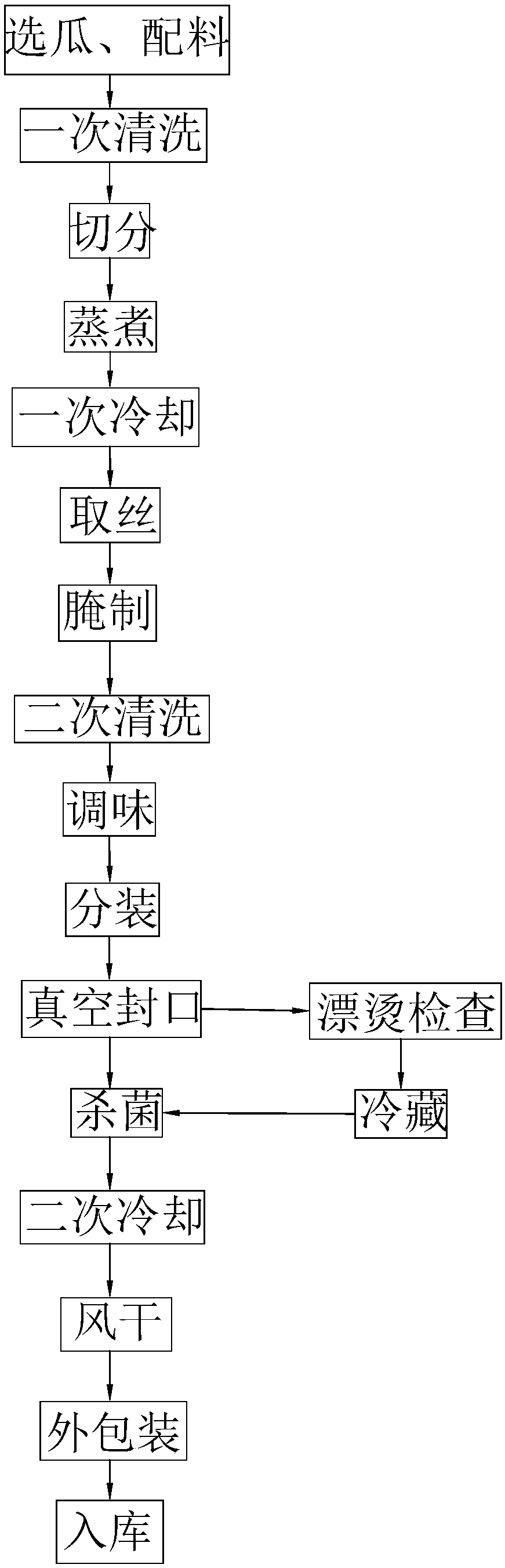

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1: a kind of processing and manufacturing method of gourd shreds comprises the following steps:

[0053] step 1:

[0054] Step 1.1. Select pumpkins that are golden in color, hard to the touch, not fluffy, and not damaged;

[0055] Step 1.2, weigh 8g of sodium chloride, 1g of sesame oil, 1g of chili oil, 3g of white sugar, 1g of monosodium glutamate, 1g of chicken essence, 1g of spices, 0.05g of potassium sorbate, and 0.03g of citric acid And the ascorbic acid of 0.03g is standby;

[0056] Step 1.3. Wash the pumpkin with clean water to remove the dust and impurities on the skin, drain the water and let it stand for 30 minutes for later use.

[0057] Step 2. Cut the pumpkin in half, remove the seeds and capsules.

[0058] Step 3: Add water to the cooking line, steam the water to 85°C, put the sliced pumpkin into the steamer for 20 minutes.

[0059] Step 4. Take out the steamed pumpkin and place it in a tray, and let it cool down to room temperature natura...

Embodiment 2

[0064] Embodiment 2: a kind of processing and manufacturing method of shredded pumpkin, comprising the following steps:

[0065] step 1:

[0066] Step 1.1. Select pumpkins that are golden in color, hard to the touch, not fluffy, and not damaged.

[0067] Step 1.2, Weigh 10g of sodium chloride, 3g of sesame oil, 2g of chili oil, 5g of white sugar, 2g of monosodium glutamate, 3g of chicken essence, 3g of spices, 0.1g of potassium sorbate, and 0.05g of citric acid And the ascorbic acid of 0.05g is standby.

[0068] Step 1.3. Wash the pumpkin with clean water to remove the dust and impurities on the skin, drain the water and let it stand for 20 minutes for later use.

[0069] Step 2. Cut the pumpkin in half, remove the seeds and capsules.

[0070] Step 3. Add water to the cooking line, steam the water to 90°C, put the sliced pumpkin into the steamer for 15 minutes;

[0071] Step 4. Take out the steamed pumpkin and place it in a tray, and let it cool down to room temperature ...

Embodiment 3

[0083] Embodiment 3: a kind of processing and manufacturing method of shredded pumpkin, comprising the following steps:

[0084] step 1:

[0085] Step 1.1. Select pumpkins that are golden in color, hard to the touch, not fluffy, and not damaged;

[0086] Step 1.2, weigh 9g of sodium chloride, 2g of sesame oil, 1.5g of spicy oil, 4g of white sugar, 1.5g of monosodium glutamate, 1.5g of chicken essence and 2.5g of spices, and 0.06g of potassium sorbate, 0.04 The citric acid of g and the ascorbic acid of 0.04g are standby;

[0087] Step 1.3. Wash the pumpkin with clean water to remove the dust and impurities on the skin, drain the water and let it stand for 30 minutes for later use.

[0088] Step 2. Cut the pumpkin in half, remove the seeds and capsules.

[0089] Step 3: Add water to the cooking line, steam the water to 85°C, put the sliced pumpkin into the steamer for 20 minutes.

[0090] Step 4. Take out the steamed pumpkin and place it in a tray, and let it cool down to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com