Preparation method of low-ester pectin stabilized composite phospholipid liposome

A technology of low-ester pectin and complex phospholipids, which is applied in liposome delivery, medical preparations of non-active ingredients, drug combinations, etc., can solve the problems of inactivation of active ingredients, reduction of nutritional value, etc., and achieve extended release period , Overcome the effect of low drug loading and reduce leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

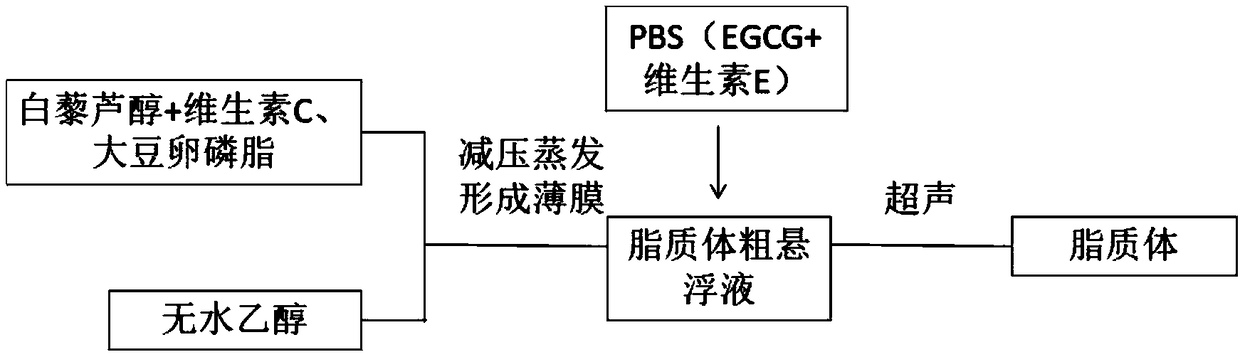

Method used

Image

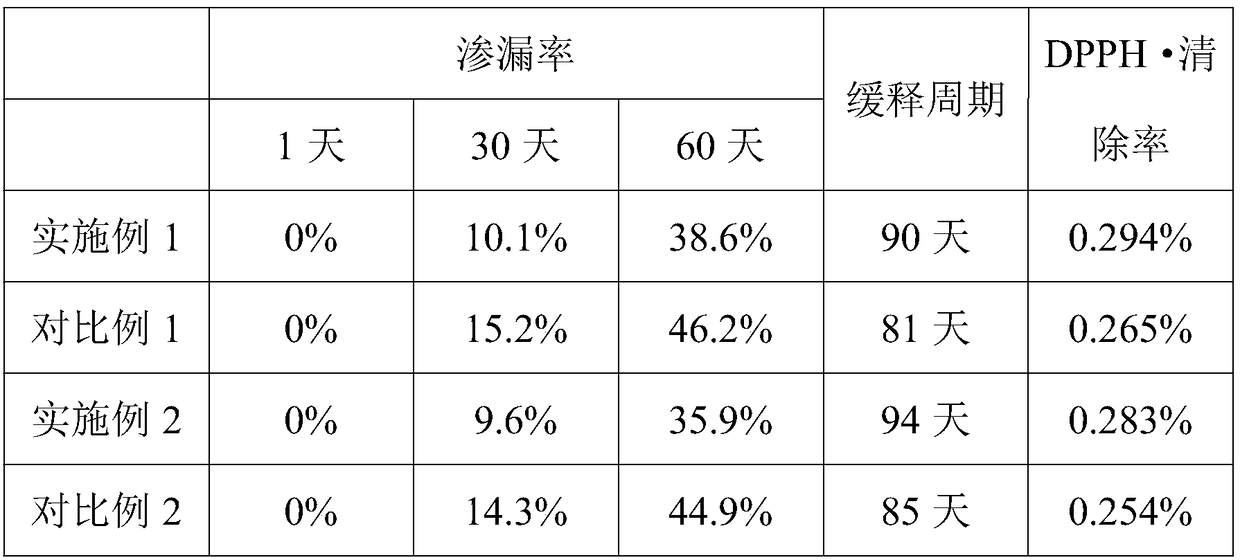

Examples

Embodiment 1

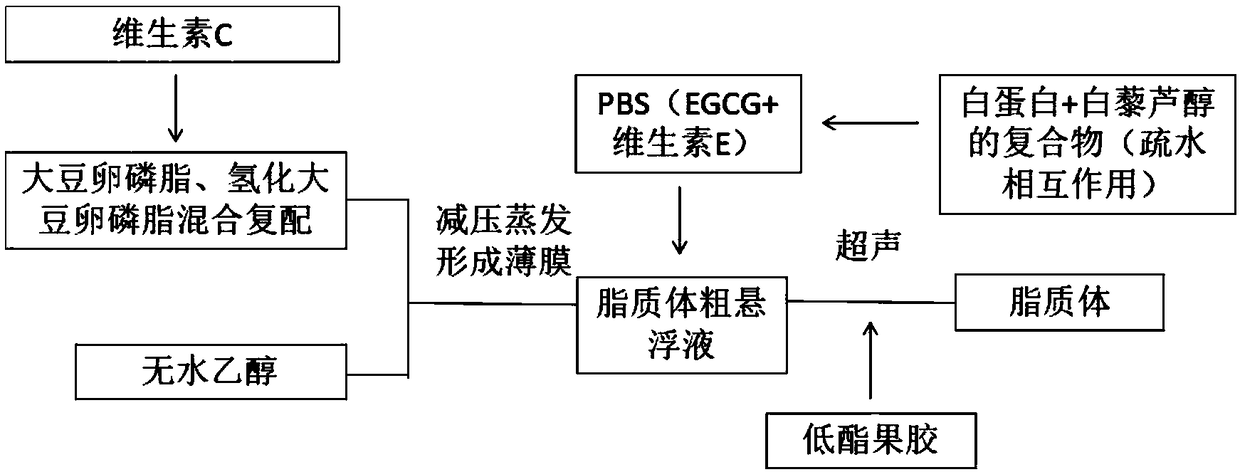

[0039] (1) Accurately weigh 80 mg of soybean lecithin, 80 mg of hydrogenated soybean lecithin, 40 mg of cholesterol, and 10 mg of vitamin C, mix them, dissolve them in 12 mL of absolute ethanol, and ultrasonicate them in a water bath at 300 W for 3 minutes until completely dissolved to obtain a mixture.

[0040] (2) The mixture obtained in step (1) was rotary evaporated under reduced pressure (vacuum degree 0.08 MPa) at 45° C. in a water bath for 40 minutes to remove ethanol until a uniform liposome film was formed on the wall of the rotary evaporation bottle.

[0041] (3) Add 20 mL of 0.05 mol / L phosphate buffer (pH=7.4) and a complex of 5 mg EGCG, 10 mg vitamin E, 5 mg albumin and 5 mg resveratrol to the rotary steamer, and place the mixture in a water bath at 45 ° C. Rotate and hydrate for 45 minutes under the conditions to obtain a liposome suspension.

[0042] (4) Configure 20mL of 0.2g / 100mL low-ester pectin aqueous solution, drop the liposome suspension into the pectin ...

Embodiment 2

[0049] (1) Accurately weigh 90 mg of soybean lecithin, 90 mg of hydrogenated soybean lecithin, 45 mg of cholesterol, and 10 mg of vitamin C, mix them, dissolve them in 10 mL of absolute ethanol, and ultrasonicate them in a water bath at 300 W for 3 minutes until completely dissolved to obtain a mixture.

[0050] (2) The mixture obtained in step (1) was rotary evaporated under reduced pressure (vacuum degree 0.08 MPa) at 45° C. in a water bath for 40 minutes to remove ethanol until a uniform liposome film was formed on the wall of the rotary evaporation bottle.

[0051] (3) Add 20 mL of 0.05 mol / L phosphate buffer (pH=7.4) and a complex of 5 mg EGCG, 10 mg vitamin E, 5 mg albumin and 5 mg resveratrol to the rotary steamer, and place the mixture in a water bath at 45 ° C. Rotate and hydrate for 45 minutes under the conditions to obtain a liposome suspension.

[0052] (4) Configure 20mL of 0.3g / 100mL low-ester pectin aqueous solution, drop the liposome suspension into the pectin ...

Embodiment 3

[0059] (1) Accurately weigh 100 mg soybean lecithin, 100 mg hydrogenated soybean lecithin, 50 mg cholesterol, and 10 mg vitamin C, mix them, dissolve them in 10 mL of absolute ethanol, and ultrasonicate them in a water bath at 300 W for 3 minutes until completely dissolved to obtain a mixture.

[0060] (2) The mixture obtained in step (1) was rotary evaporated under reduced pressure (vacuum degree 0.08 MPa) at 45° C. in a water bath for 40 minutes to remove ethanol until a uniform liposome film was formed on the wall of the rotary evaporation bottle.

[0061] (3) Add 20 mL of 0.05 mol / L phosphate buffer (pH=7.4) and a complex of 5 mg EGCG, 10 mg vitamin E, 5 mg albumin and 5 mg resveratrol to the rotary steamer, and place in a water bath at 45 ° C. Rotate and hydrate for 45 minutes under the conditions to obtain a liposome suspension.

[0062] (4) Configure 20mL of 0.2g / 100mL low-ester pectin aqueous solution, drop the liposome suspension into the pectin solution, mix and stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com