Ag2S-MMt nanometer composite adsorbent and preparation method thereof

A nano-composite and adsorbent technology, applied in the field of composite materials, can solve the problem of high complexity and high cost, and achieve the effects of good economy, low price and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solution of the present invention will be described in detail below according to the drawings and specific embodiments.

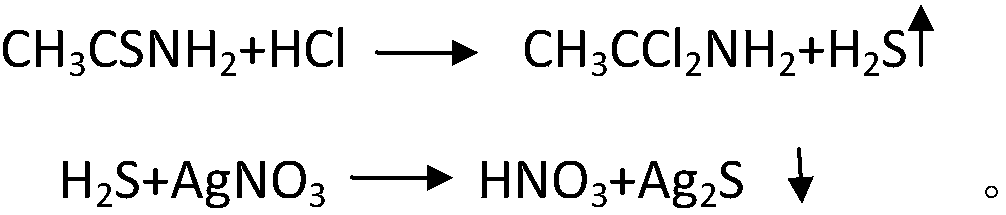

[0036] Ag of the present invention 2 The preparation method of S-MMT nanocomposite adsorbent is:

[0037] The first step: preparation of montmorillonite (MMT) dispersion

[0038] Weigh bentonite and place it in a container, add deionized water therein, and stir for 9 hours on a magnetic stirrer to fully swell and disperse bentonite to obtain a dispersion whose main component is montmorillonite. The prepared montmorillonite dispersion molar The concentration is 15g / L;

[0039] Step 2: Preparation of loaded Ag + MMT dispersion

[0040] Add AgNO to the montmorillonite dispersion prepared in the first step 3 Solution, continue to stir on the magnetic stirrer for 3h, so that Ag + Adsorbed on the surface of MMT, the molar number of silver nitrate loaded in the prepared dispersion per gram of bentonite is 0.001mol / g;

[0041]The third s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com