Method of treating sludge by adopting self-propagating pyrolyzation device coordinated with cement plant

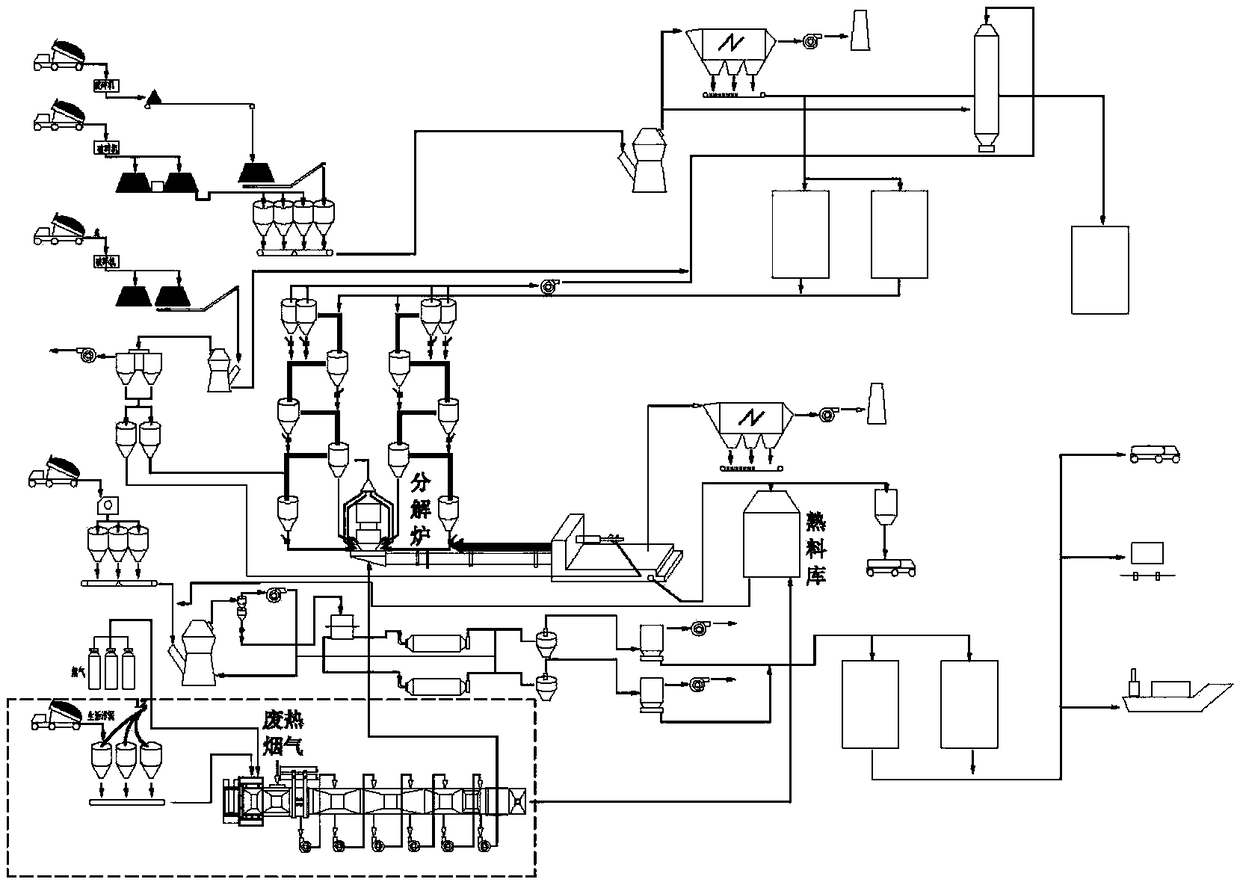

A self-propagating, cement plant technology, applied in the field of sludge treatment in self-propagating pyrolysis devices, can solve the problems of long incineration residence time, large treatment scale, large incineration space, etc. The effect of the location dilemma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

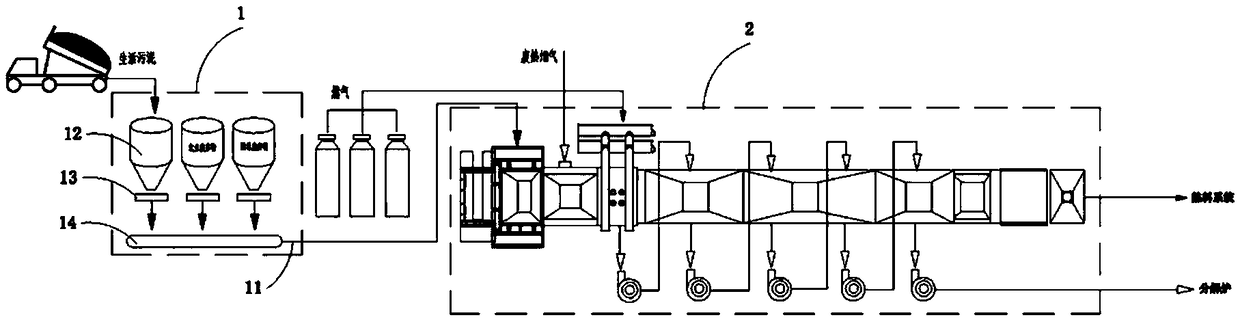

[0020] A method for treating sludge with a self-propagating pyrolysis device in a collaborative cement plant, comprising the following steps

[0021] (1) Pretreatment: the green auxiliary material and the sludge in the material storage bin 12 are weighed by the metering device 13, transported into the mixing device 14 in a ratio of 1:5, and then mixed uniformly to form a mixed material, the green auxiliary material The particle size is 2-30mm;

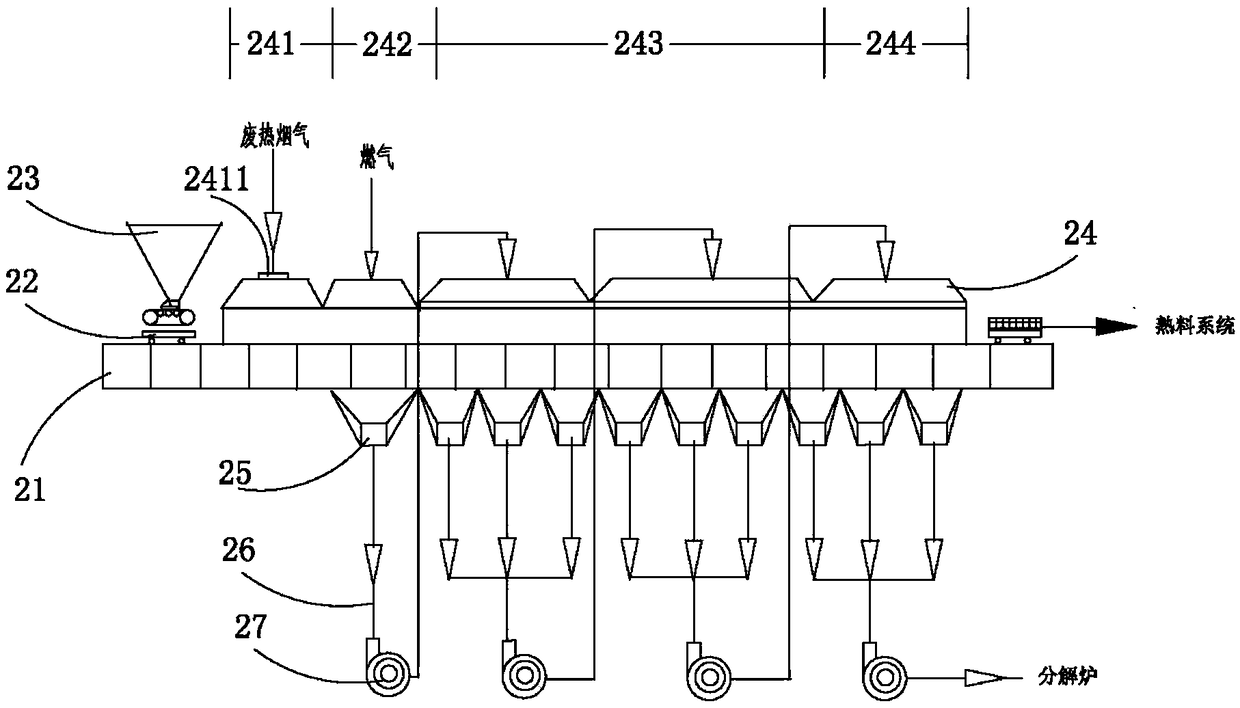

[0022] (2) Pyrolysis of step-by-step / chain-belt self-propagating pyrolysis device: transport the mixed material to the distributor 23, and the distributor 23 arranges the mixed material on the trolley 22 or the chain belt 282 below the distributor 23 to form a material layer, so that the material layer passes into the preheating section 241, the ignition section 242, the pyrolysis section 243 and the cooling section 244 in sequence. In the ignition section 242, the sludge is ignited by gas combustion, and the incompletely burned flue ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com