Preparation method of high-aluminum borosilicate glass with excellent dielectric properties

A technology of dielectric properties and borosilicate glass, which is applied in the field of high-alumina borosilicate glass preparation, can solve problems such as rising melting temperature, high melting temperature environmental hazards, low dielectric constant, etc., to achieve accelerated melting, excellent dielectric Constant, the effect of satisfying the thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step 1), according to raw material mole fraction, accurately weigh 67.64% quartz sand, 9.83% boric anhydride, 11.06% alumina powder, 2.24% magnesium oxide, 8.62% calcium oxide, 0.54% strontium oxide and 0.07% % tin oxide;

[0027] Step 2), put the weighed raw materials into the mixer in turn, and mix until the uniformity is greater than 99% to form a batch;

[0028] Step 3), preheat the alumina crucible to 1450°C with the furnace, and add batch materials; then, heat up to 1680°C for 50-60 minutes, and keep the temperature for 240 minutes;

[0029] Step 4), put the glass into an annealing furnace, and anneal at 740-760°C;

[0030] In step 5), the temperature is lowered to room temperature at a cooling rate of 1-3° C. / min to obtain a high-alumina borosilicate glass with excellent dielectric properties.

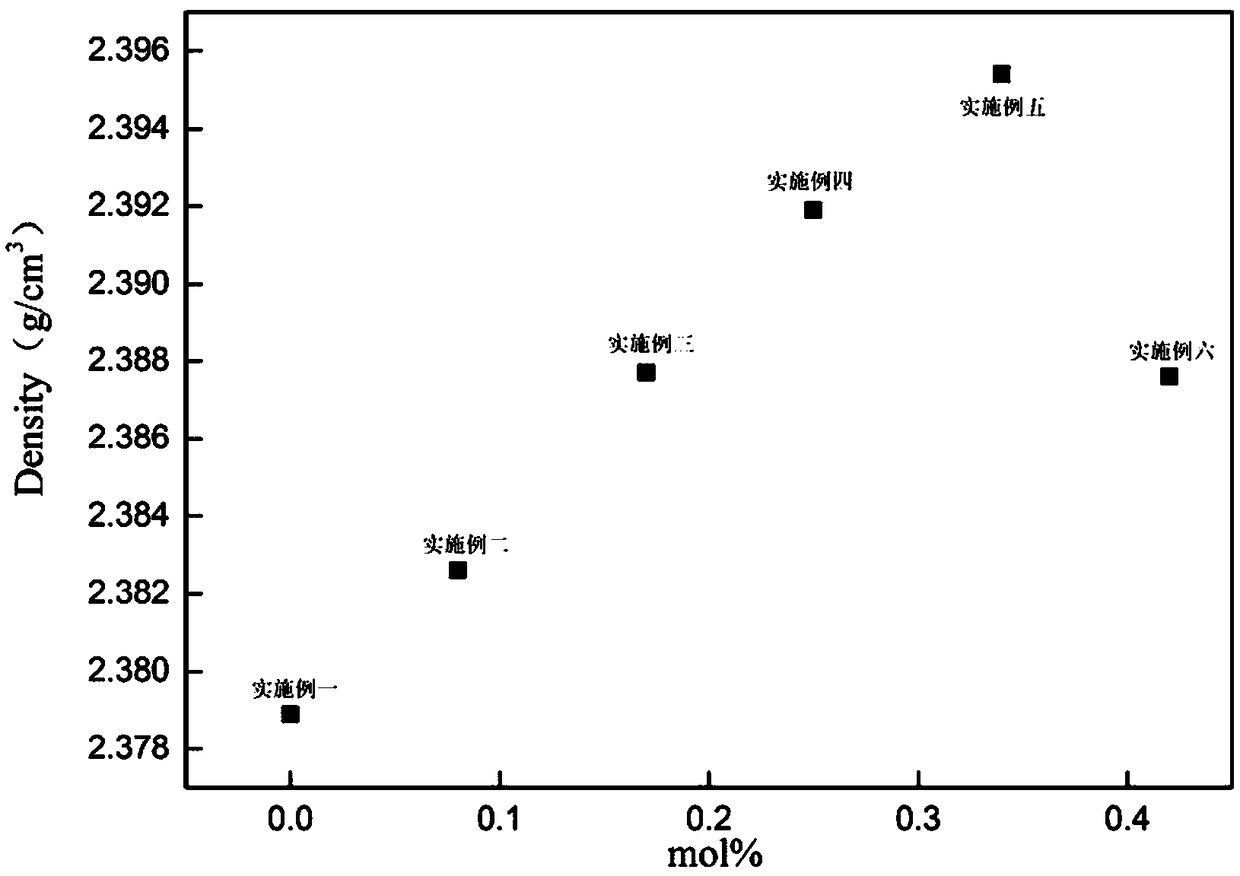

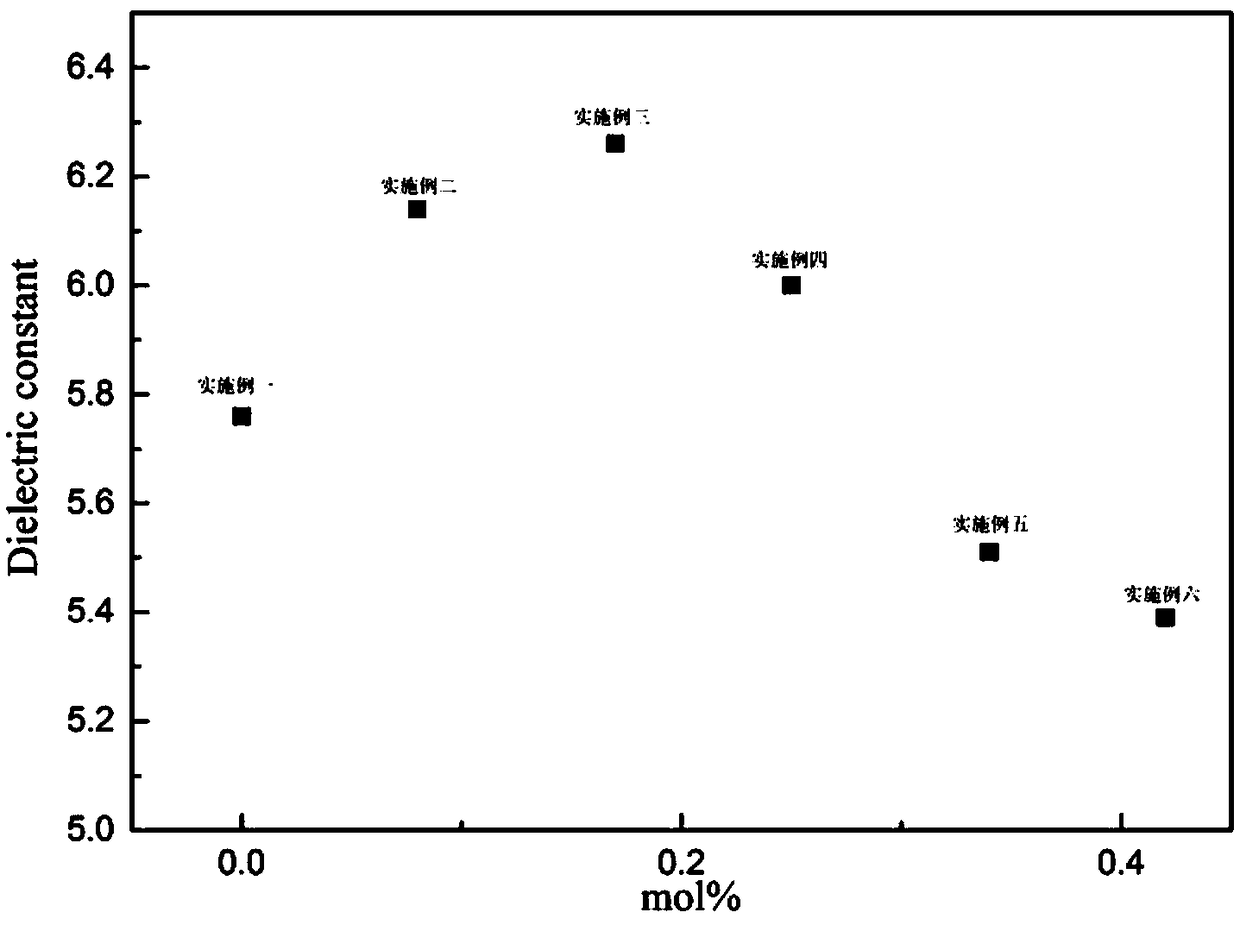

[0031] see figure 1 with him figure 2 As shown, the density of high-alumina borosilicate glass with excellent dielectric properties measured by ASTM C-693 standard i...

Embodiment 2

[0033] Step 1), according to raw material mole fraction, accurately weigh 67.57% quartz sand, 9.83% boric anhydride, 11.05% alumina powder, 2.24% magnesium oxide, 8.62% calcium oxide, 0.54% strontium oxide, 0.08 % barium oxide and 0.07% tin oxide;

[0034] Step 2), put the weighed raw materials into the mixer in turn, and mix until the uniformity is greater than 99% to form a batch;

[0035]Step 3), preheat the alumina crucible to 1450°C with the furnace, and add batch materials; then, heat up to 1680°C for 50-60 minutes, and keep the temperature for 240 minutes;

[0036] Step 4), put the glass into an annealing furnace, and anneal at 740-760°C;

[0037] In step 5), the temperature is lowered to room temperature at a cooling rate of 1-3° C. / min to obtain a high-alumina borosilicate glass with excellent dielectric properties.

[0038] see figure 1 with him figure 2 As shown, the density of high-alumina borosilicate glass with excellent dielectric properties measured by AST...

Embodiment 3

[0040] Step 1), according to raw material mole fraction, accurately weigh 67.50% quartz sand, 9.82% boric anhydride, 11.04% alumina powder, 2.24% magnesium oxide, 8.62% calcium oxide, 0.54% strontium oxide, 0.17% % barium oxide and 0.07% tin oxide;

[0041] Step 2), put the weighed raw materials into the mixer in turn, and mix until the uniformity is greater than 99% to form a batch;

[0042] Step 3), preheat the alumina crucible to 1450°C with the furnace, and add batch materials; then, heat up to 1680°C for 50-60 minutes, and keep the temperature for 240 minutes;

[0043] Step 4), put the glass into an annealing furnace, and anneal at 740-760°C;

[0044] In step 5), the temperature is lowered to room temperature at a cooling rate of 1-3° C. / min to obtain a high-alumina borosilicate glass with excellent dielectric properties.

[0045] see figure 1 with him figure 2 As shown, the density of high-alumina borosilicate glass with excellent dielectric properties measured by A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com