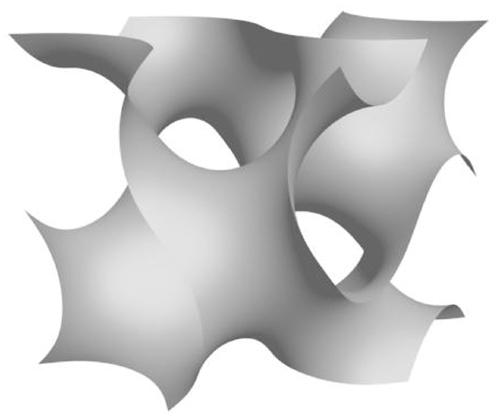

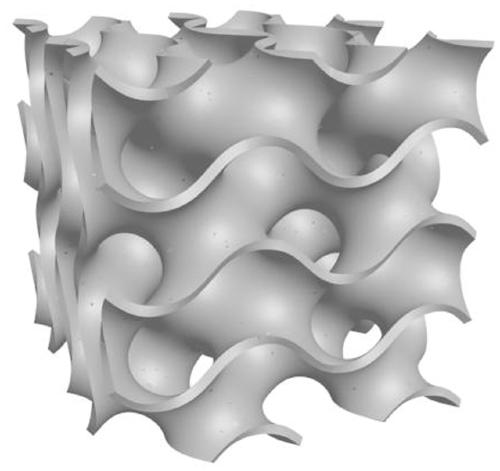

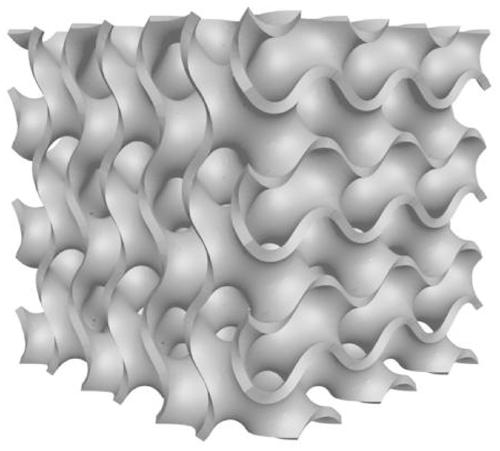

Preparation method of foamed aluminum of twenty-four-face spiral body structure

A technology of tetrahedron and helical structure, which is applied in the field of aluminum foam preparation, can solve the problem of inability to achieve precise control of pore distribution and size control, poor porosity, pore structure uniformity and connectivity, and insufficient stability of pore structure forming, etc. problems, to achieve more diverse spatial arrangements, good connectivity, and overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Step 1. Use the fused deposition 3D printer to directly print the helical structure of the designed PLA material, with a layered thickness of 0.1mm, a cube in the range of 4×4×4cm, a period parameter of 2, and a surface thickness of 1mm;

[0019] Step 2, fix the spiral structure obtained in step 1 in the mold, pour the mixed gypsum slurry into the mold, the retarder is sodium polyphosphate, the adhesive is epoxy resin, the gypsum slurry, poly The mass ratio of sodium phosphate to epoxy resin is 45:45:10. At the same time, a certain amount of mechanical vibration is applied; after the slurry is hardened, melt the PLA material in a drying oven at 200°C for 20 minutes, then pour the PLA melt, clean it, and then bake it in a roasting furnace at 3°C Raise the temperature to 200°C / min, then raise the temperature to 700°C at 10°C / min, keep it for 5 hours, then cool it down to 300°C at 5°C / min, and hold it for 3 hours to obtain a porous prefabricated block with a helicoid struc...

Embodiment 2

[0024] Step 1. Use the fused deposition 3D printer to directly print the helical structure of the designed PLA material, with a layered thickness of 0.1mm, a cube in the range of 4×4×4cm, a period parameter of 3, and a surface thickness of 1mm;

[0025] Step 2. Fix the spiral structure obtained in step 1 in the mold, pour the mixed gypsum slurry into the mold, the retarder is sodium polyphosphate, and the epoxy resin is the adhesive, and the mass ratio is 45:45 :10. At the same time, a certain amount of mechanical vibration is applied; after the slurry is hardened, melt the PLA material in a drying oven at 200°C for 20 minutes, then pour the PLA melt, clean it, and then bake it in a roasting furnace at 3°C Raise the temperature to 200°C / min, then raise the temperature to 700°C at 10°C / min, keep it for 5 hours, then cool it down to 300°C at 5°C / min, and hold it for 3 hours to obtain a porous prefabricated block with a helicoid structure ;

[0026] Step 3, heating the aluminum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com