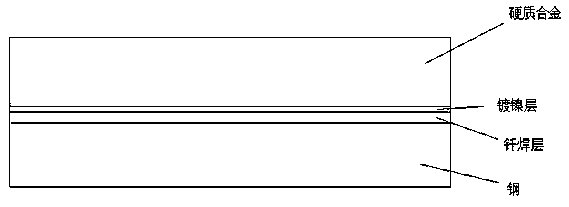

Cemented carbide and steel vacuum diffusion welding process

A cemented carbide and vacuum diffusion technology, which is applied in metal material coating technology, welding equipment, metal processing equipment, etc., can solve the problems of difficult melting of base metal, easy oxidation of cemented carbide, and micro-cracks in weld welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A vacuum diffusion welding process for cemented carbide and steel.

[0023] Pre-welding treatment: rough grinding the spreading test surface and brazing surface of the cemented carbide and steel on a diamond grinder, coating the cast iron block with diamond paste, and finally placing the spreading surface and brazing surface on the cast iron Grind until the surface is bright, rough-grind the 45 steel on the grinder, and then polish the spread test surface and the brazing surface with metallographic sandpaper. The solder CuMnNi is cut into slices, and the size is slightly larger than the brazing surface. Ensure that the amount of solder is enough to fill the brazing gap, polish the solder and iron sheet with metallographic sandpaper to remove the oxide layer;

[0024] During brazing, soak all the polished materials in acetone for 5-10 minutes, scrub them, and then take them out and blow dry to prevent the sample from being contaminated again. Vacuum diffusion brazing is requi...

Embodiment 2

[0033] Pre-welding treatment: Coarse the spreading test surface and brazing surface of the cemented carbide and steel on a diamond grinder, then apply diamond paste on the cast iron block, and finally place the spreading surface and brazing surface on the cast iron Grind until the surface is bright; rough-grind the 45 steel on a grinder, and then polish the spread test surface and brazing surface with metallographic sandpaper; cut the solder iron sheets into slices, the size should be slightly larger than the brazing surface To ensure that the amount of solder is sufficient to fill the brazing gap, polish the solder and iron sheet with metallographic sandpaper to remove the oxide layer;

[0034] During brazing, soak all the polished materials in acetone for 5-10 minutes, scrub them, and then take them out and blow dry to prevent the sample from being contaminated again. Vacuum diffusion brazing is required as soon as possible;

[0035] The pretreated cemented carbide is subjected t...

Embodiment 3

[0044] Pre-welding treatment: Coarse the spreading test surface and brazing surface of the cemented carbide and steel on a diamond grinder, then apply diamond paste on the cast iron block, and finally place the spreading surface and brazing surface on the cast iron Grind until the surface is bright; rough-grind the 45 steel on a grinder, and then polish the spreading test surface and the brazing surface with metallographic sandpaper; cut the CuMnTi brazing material into slices, the size should be slightly larger than the brazing surface, To ensure that the amount of solder is sufficient to fill the brazing gap, polish the solder and iron sheet with metallographic sandpaper to remove the oxide layer;

[0045] During brazing, soak all the polished materials in acetone for 5-10 minutes, scrub them, and then take them out and blow dry to prevent the sample from being contaminated again. Vacuum diffusion brazing is required as soon as possible;

[0046] The pretreated cemented carbide i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com