0-3 bismuth ferrite based magnetoelectric composite material and preparation method thereof

A technology of magnetoelectric composite material and bismuth ferrite, which is applied in the field of functional materials to achieve the effect of improving ferromagnetism and magnetoelectric coupling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] At the same time, the application also provides the preparation method of the 0-3 bismuth ferrite-based magnetoelectric composite material, comprising the following steps:

[0035] The bismuth source, iron source, barium source and titanium source are dosed according to the relative ratio of each component in the 0-3 bismuth ferrite-based magnetoelectric composite material shown in formula (I);

[0036] The raw materials after batching are ball-milled and then synthesized to obtain a synthetic powder;

[0037] After ball milling the synthetic powder, adding a binder and sintering to obtain a 0-3 bismuth ferrite-based magnetoelectric composite material;

[0038] (1-y) Bi (1-x) FeO (3-1.5x) -yBaTiO 3 (I);

[0039] Wherein, 0

[0040] In the above-mentioned process of preparing 0-3 bismuth ferrite-based magnetoelectric composite materials, the present application adopts the commonly used ferroelectric ceramic preparation process without prior synthesis ...

Embodiment 1

[0054] Preparation of 0.75BiFeO by a traditional solid-state sintering method 3 -0.25BaTiO 3 ceramics. According to the stoichiometric ratio of the above ceramic materials, Bi 2 o 3 , Fe 2 o 3 、BaCO 3 and TiO 2 (Analytical grade, Sinopharm Group) according to the ratio, put it into a ball mill tank, add alcohol and ball mill for 12 hours, then dry it, heat it at 850°C for 1h, and heat it at 940°C for 1h to synthesize; then ball mill the synthesized powder, add appropriate binder Pressed into a disc with a diameter of 25.4 mm, and sintered at 1000 ° C for 4 hours to obtain a ceramic sample with a diameter of about 21 mm.

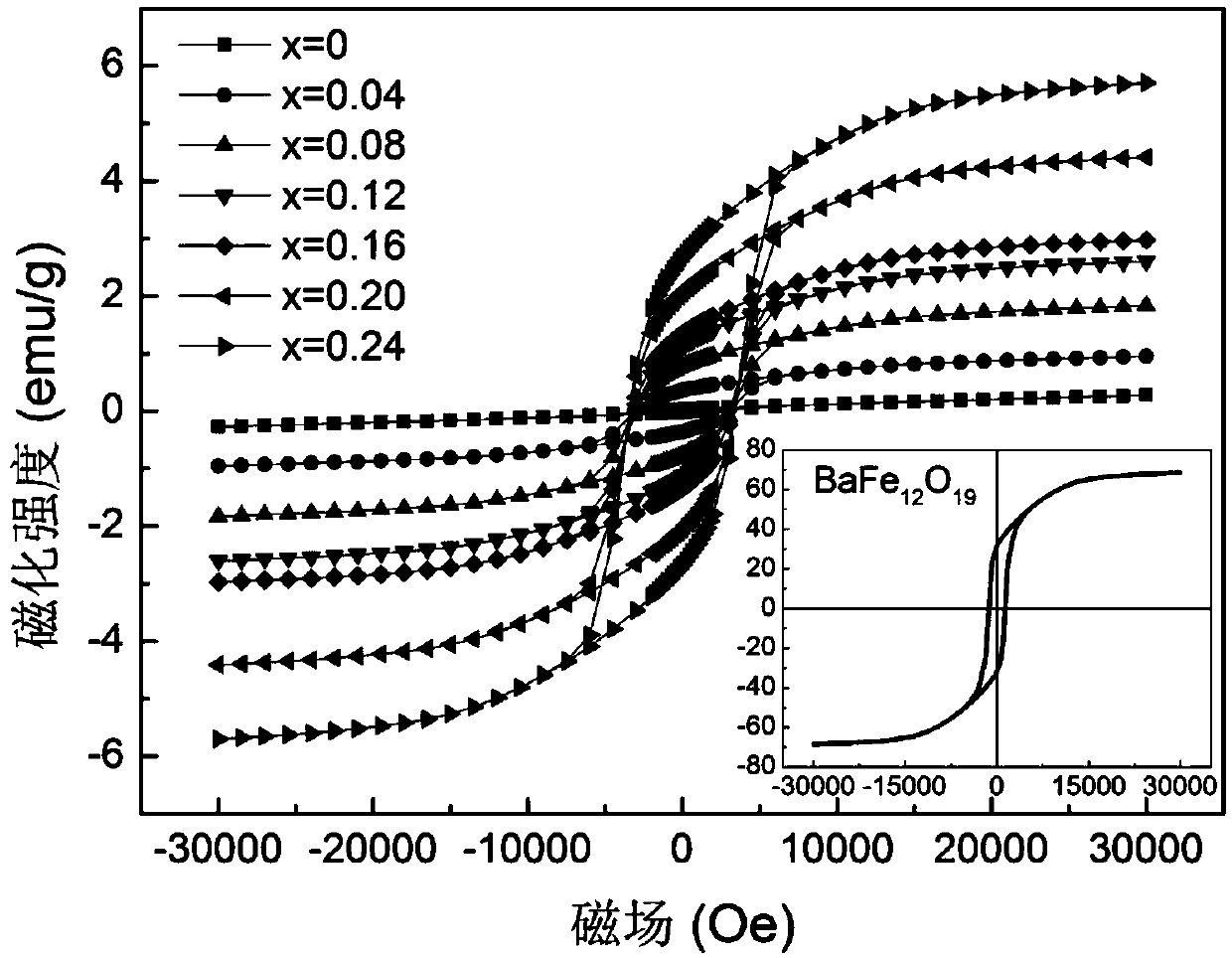

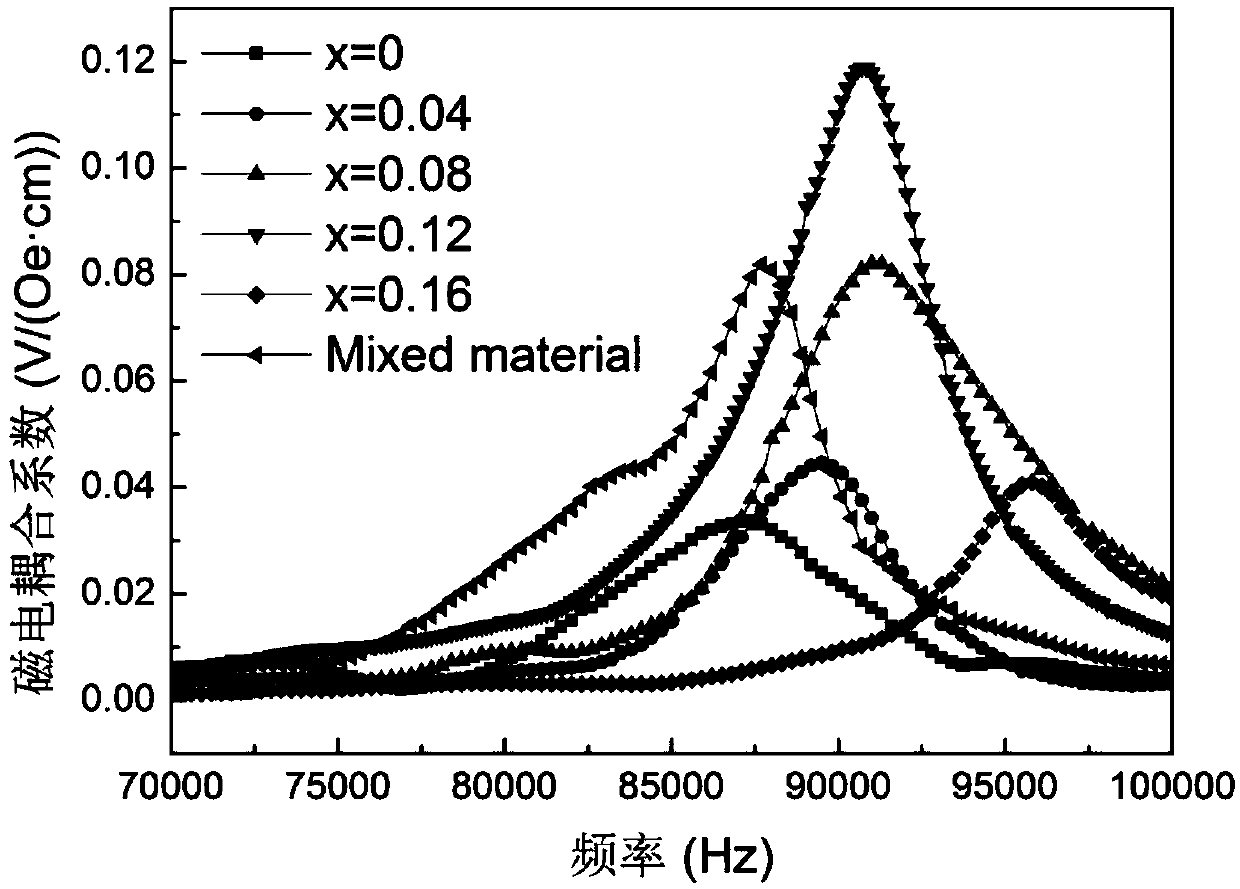

[0055] The ceramic sheet was polished on both sides, and the microstructure, piezoelectric coefficient, residual magnetization and magnetoelectric coupling coefficient of the sample were tested. Figure 4 The cross-sectional backscattering spectrum of the sample shows that the stoichiometric bismuth ferrite-barium titanate solid solution (x=0) is a sa...

Embodiment 2

[0057] The 0.75Bi of non-stoichiometric ratio is prepared by adopting the same method method as in example 1 (1-x) FeO (3-1.5x) -0.25BaTiO 3 For ceramics, x=0~0.24 (x is not equal to 0). The ceramic sheet was polished on both sides, and the microstructure, piezoelectric coefficient, residual magnetization and magnetoelectric coupling coefficient of the sample were tested.

[0058] Figure 4 The backscattering spectrum of the cross-section shows very intuitively the distribution of the second phase with x values of 0, 0.12 and 0.24; from Figure 4 It can be seen from the figure that with the increase of the degree of bismuth deficiency, the content of the second phase shows an obvious increasing trend, and the distribution of the second phase always maintains a uniform state.

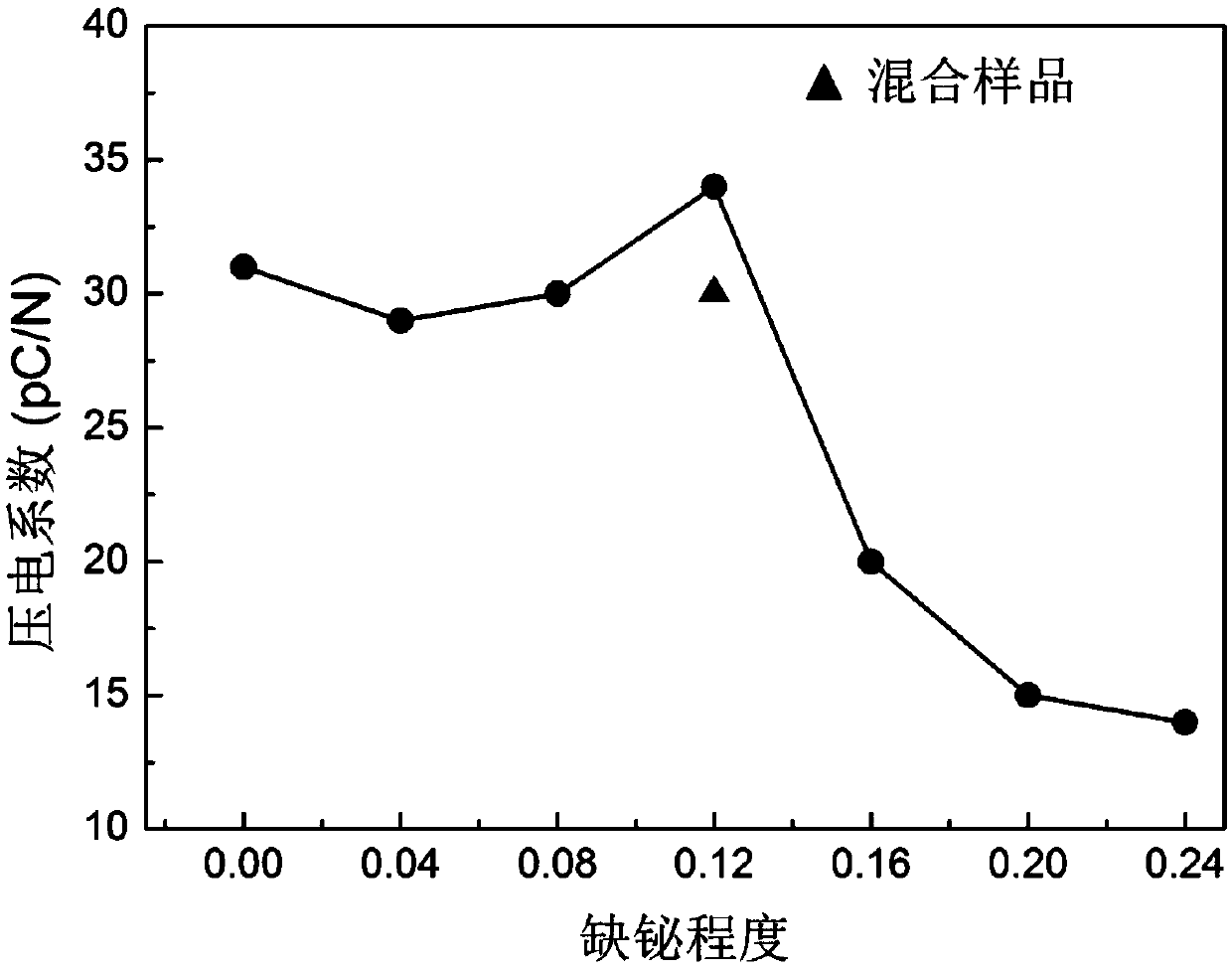

[0059] Such as figure 1 As shown, in the range of x = 0 ~ 0.12, the piezoelectric coefficient of the sample fluctuates between 30 ~ 35pC / N, without much change, and after x exceeds 0.12, with the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Piezoelectric coefficient | aaaaa | aaaaa |

| Residual magnetization | aaaaa | aaaaa |

| Piezoelectric coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com