Application technology of silicon carbide waste to ferrosilicon and silicomanganese production

A technology for producing waste and silicomanganese alloys, which is applied in the production of silicomanganese alloys and ferrosilicon, can solve the problems of not being able to realize environmental protection, not being able to improve the content of trace elements in alloys, and not being able to increase the recycling rate of resources, so as to increase the rate of recycling , to achieve recycling, to improve the effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

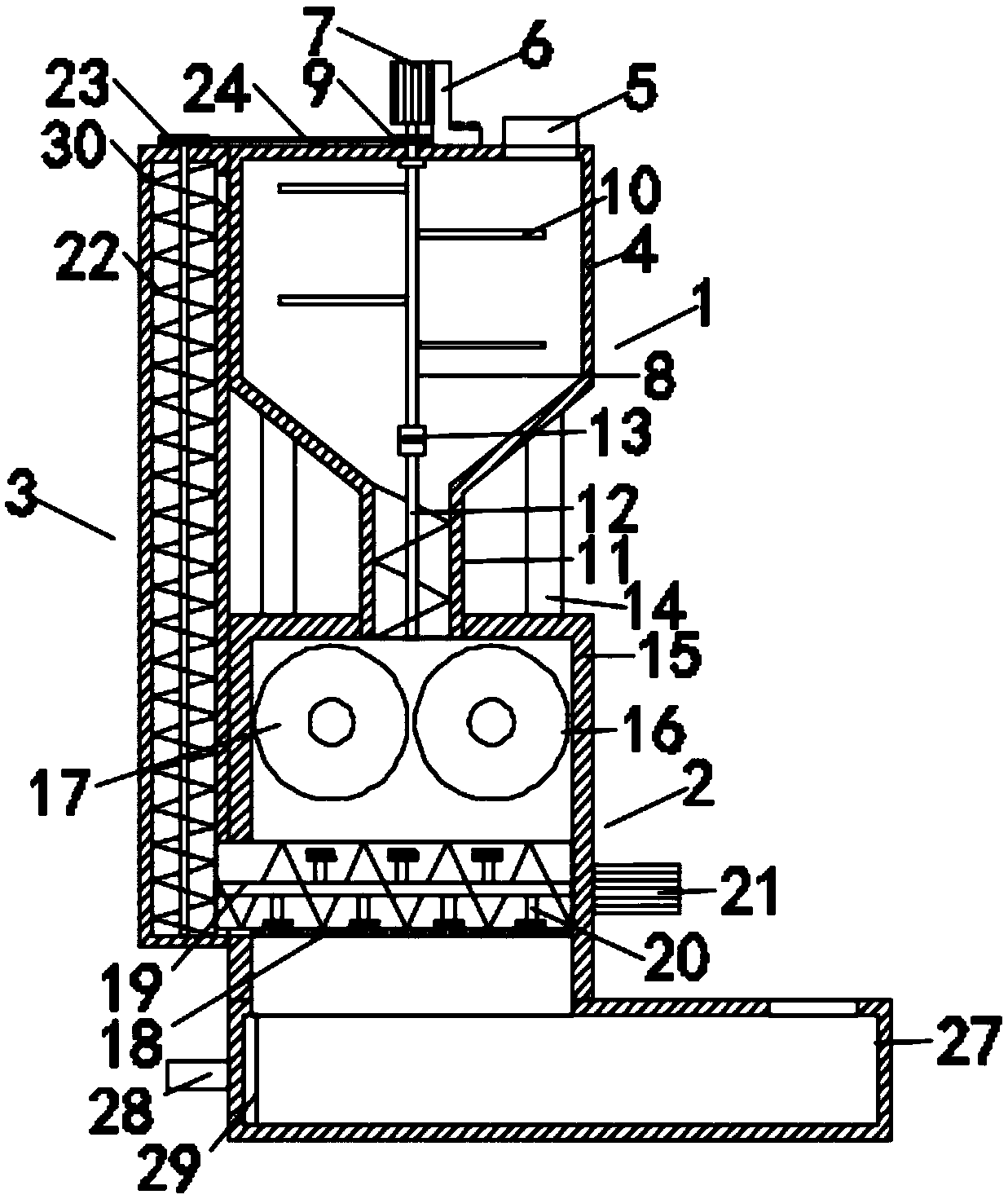

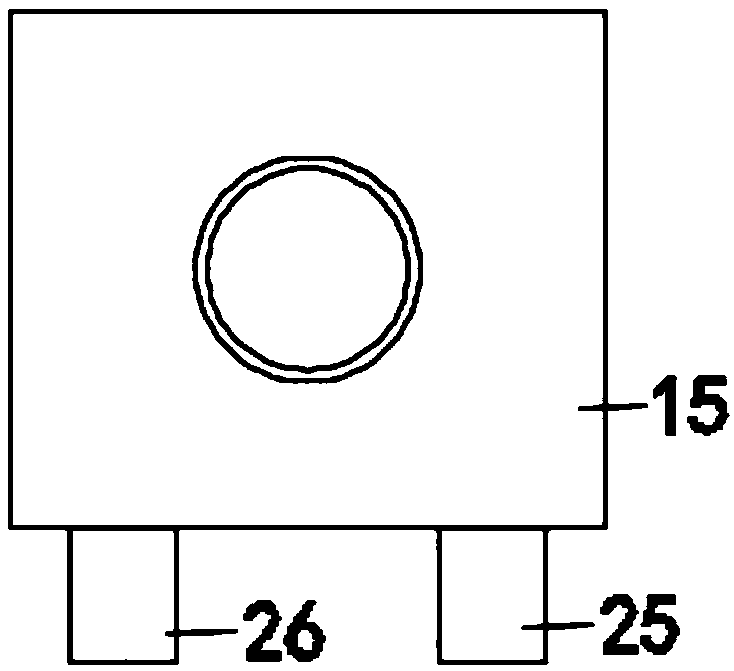

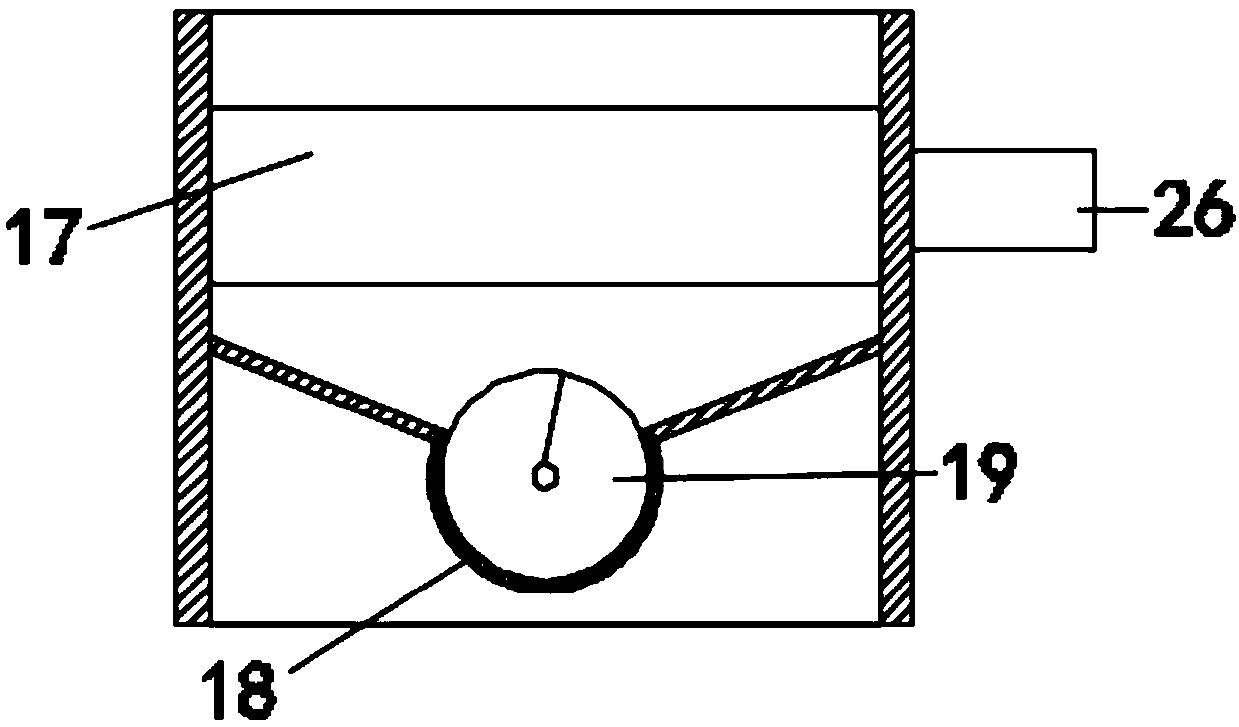

[0025] like Figure 1-3 As shown, the specific implementation mode adopts the following technical solutions: the application process of silicon carbide production waste in the production of ferrosilicon and silicon-manganese alloys, including the following steps:

[0026] A. Waste collection: collect impurity waste outside the silicon carbide crystallization cylinder;

[0027] B. Waste processing: Circularly process and grind the waste through the waste treatment device, collect the grinding waste, remove relevant impurities, and store the obtained waste for future use;

[0028] C. Ferrosilicon and silicon-manganese alloy raw materials: mix manganese ore, manganese sintered ore, manganese-rich slag, silica, dolomite or limestone, reducing agent and silicon carbide production waste in proportion;

[0029] D. Ferrosilicon and silicon-manganese alloy processing: put the mixed raw material obtained in step C into submerged arc furnace for reaction, and adopt slag-bearing method f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com