Temperature-controlled shape memory blocking agent and preparation method

A technology of memory and plugging agent, which is applied in earthwork drilling, wellbore/well components, sealing/isolation, etc. It can solve the problem of limiting the plugging effect of fiber plugging slurry, affecting the rheological properties of cement slurry, and slow fiber speed, etc. problems, to achieve the effect of increasing toughness, increasing apparent volume, and efficient plugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Preparation of Styrene-Butadiene Copolymer Based Oil Well Cement with Shape Memory Particles, Cement Slurry and Cement Stone Module

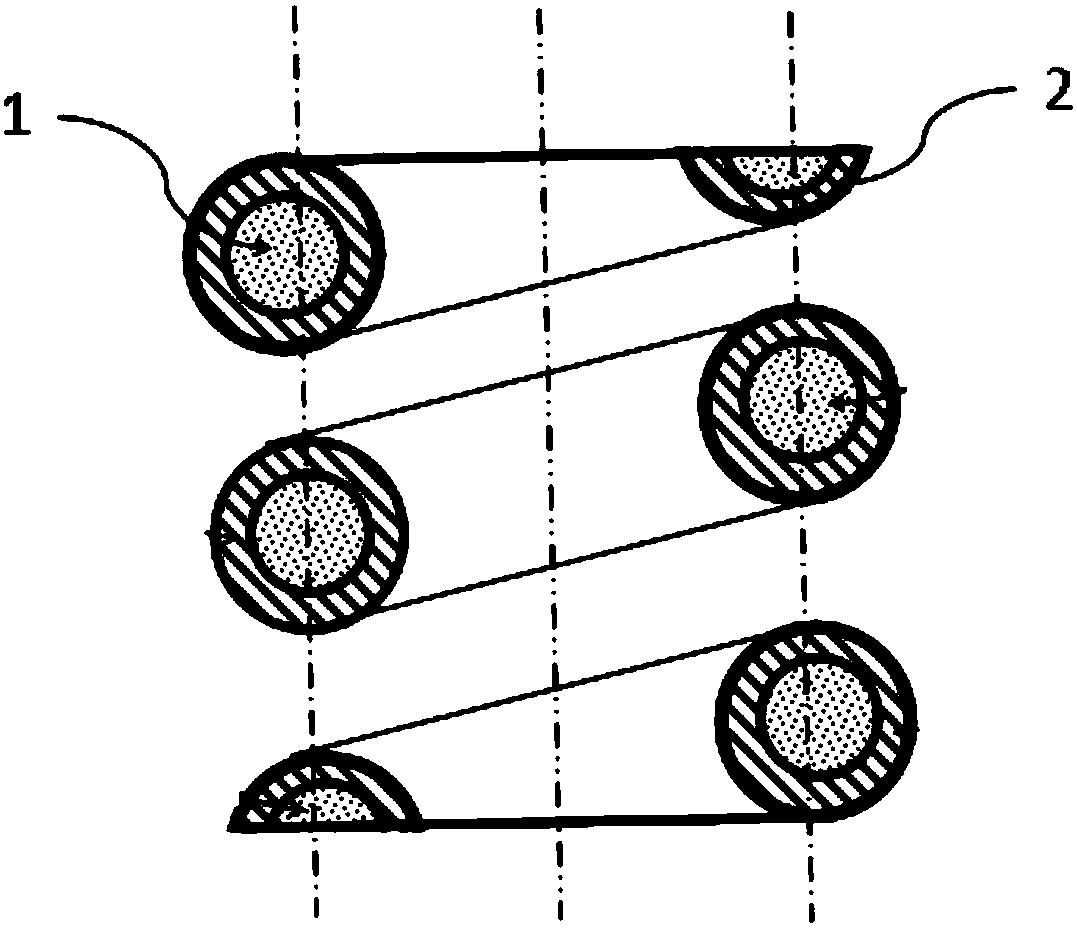

[0062] A styrene-butadiene shape-memory polymer whose shape-memory deformation temperature is 55-60° C. is crushed into a shape-memory polymer powder of 0.16-0.5 mm by cryogenic freezing.

[0063] The spring is carbon steel wire spring; 1.5mm after spring compression, 7.5mm before compression and after recovery;

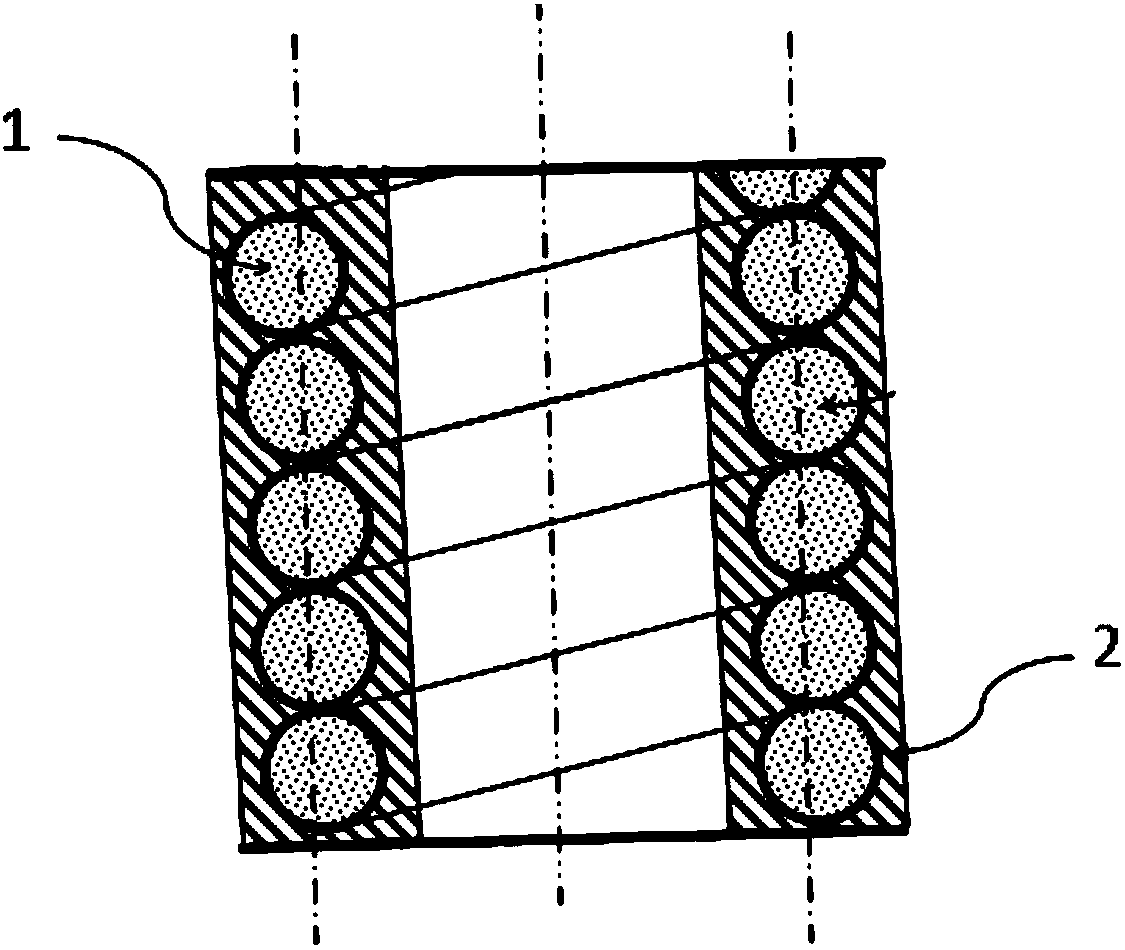

[0064] heating and melting the shape memory polymer powder, coating and mixing the uncompressed spring and the shape memory polymer hot melt solution, each accounting for 50% by mass; cooling the uniformly mixed material to 55-75°C, and compressing, Made into a compression spring, cooled to room temperature.

[0065] The compressed spring wire is granulated with a cutting granulator, and the size of the granulation is controlled to be less than 3mm in diameter and length, such as 0.5mm, 1mm, 2mm, and 3mm, so as to facilitate mi...

Embodiment 2

[0069] Preparation of shape memory particles, cement paste and cement stone modules for oil well cement based on polyurethane copolymer

[0070] A polyurethane shape-memory polymer whose shape-memory deformation temperature is 65-70° C. is crushed into a shape-memory polymer powder of 0.07-0.16 mm by cryogenic freezing.

[0071] The spring is 50% chrome vanadium steel wire spring and 50% copper wire spring. Chrome vanadium steel wire spring is 1mm after compression, 6mm before compression and after recovery; copper wire spring is 0.5mm after compression, 5mm before compression and after recovery.

[0072] The shape memory polymer powder is heated and melted, and the uncompressed spring and the shape memory polymer hot melt are coated and mixed evenly, and the mass ratio of the spring and the shape memory polymer powder is 80% and 20% respectively; the uniformly mixed The material is cooled to 65-85°C, compressed to make a compression spring, and cooled to room temperature.

...

Embodiment 3

[0077] Preparation of shape-memory particles, cement paste and cement stone modules for oil well cement based on polyvinyl acetal gel and ethylene-vinyl acetate copolymer

[0078] A kind of polyvinyl acetal gel and ethylene-vinyl acetate copolymer whose shape memory deformation temperature is 65-70 DEG C are crushed into 0.05-0.16mm mesh by low-temperature freezing.

[0079] The spring is a carbon steel wire spring. 1.2mm after spring compression, 7mm before compression and after recovery.

[0080] The shape memory polymer powder is heated and melted, the uncompressed spring and the shape memory polymer hot melt are coated and mixed evenly, and the mass ratio of the spring and the shape memory polymer powder is 20% and 80% respectively; the uniformly mixed The material is cooled to 65-85°C, compressed to make a compression spring, and cooled to room temperature.

[0081] The compressed spring wire is granulated with a cutting granulator, and the size of the granulation is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com