High-sensitivity capacitive flexible tactile sensor based on three-dimensional porous microstructure composite dielectric layer and manufacturing method thereof

A tactile sensor, three-dimensional porous technology, which is applied in nanotechnology, instruments, and measuring devices for materials and surface science, and can solve problems such as poor stability, low sensitivity of flexible tactile sensors, and cumbersome preparation of composite dielectric layer microstructures. , to achieve the effects of improving sensitivity, easy regulation of electrical characteristics, and easy regulation of mechanical characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

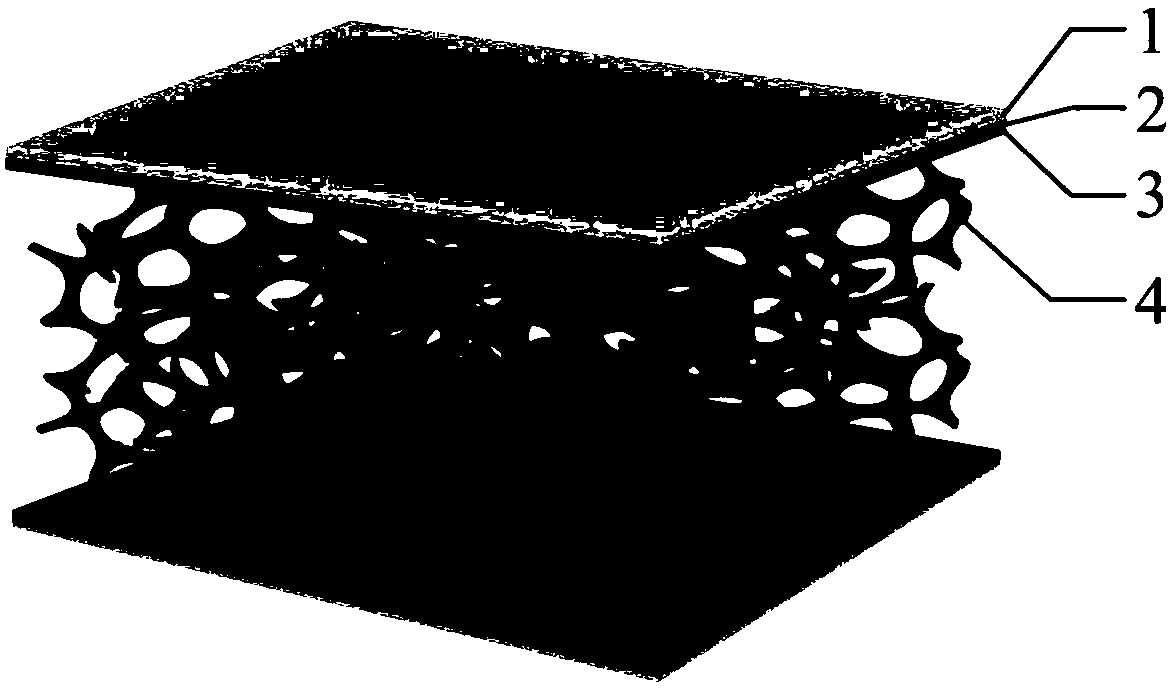

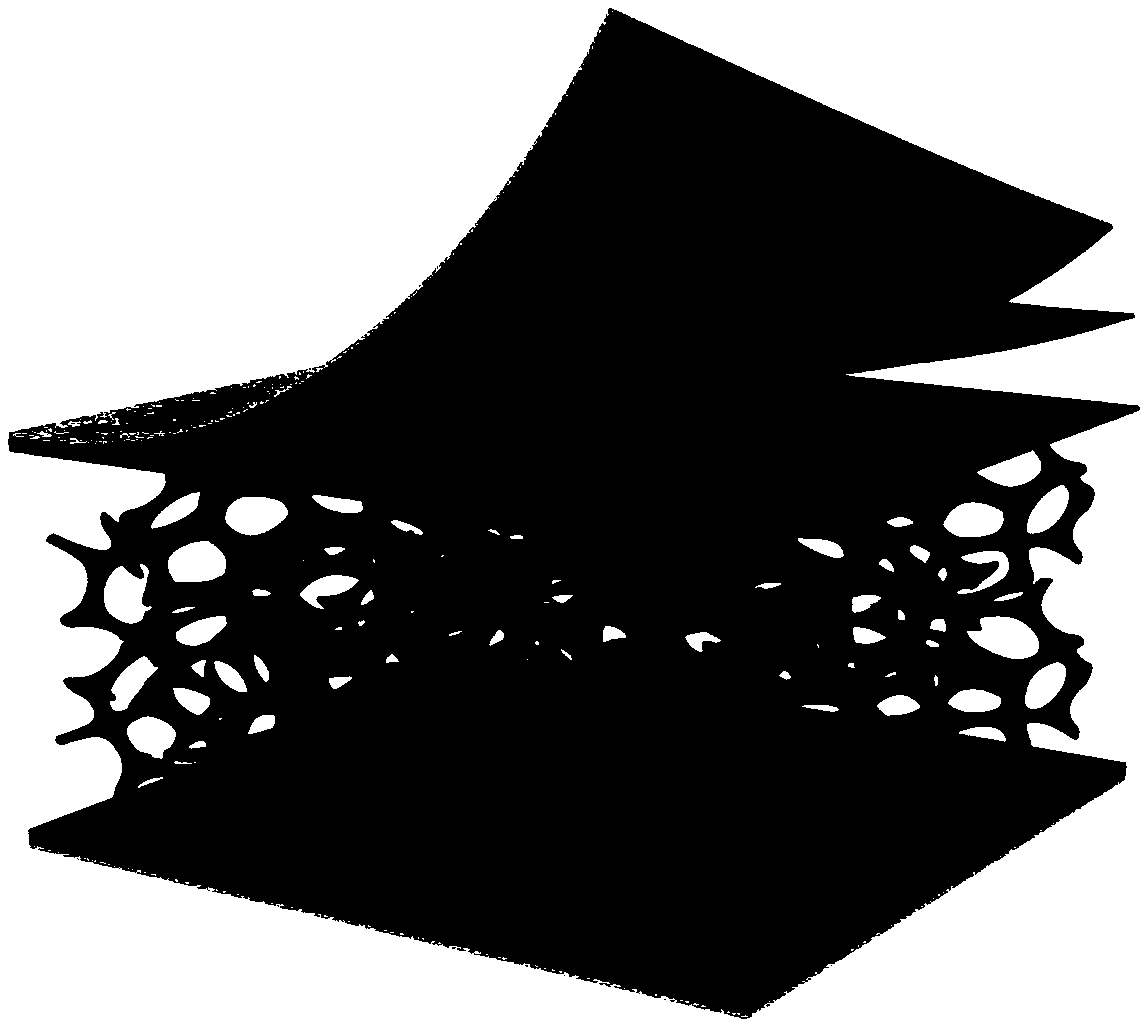

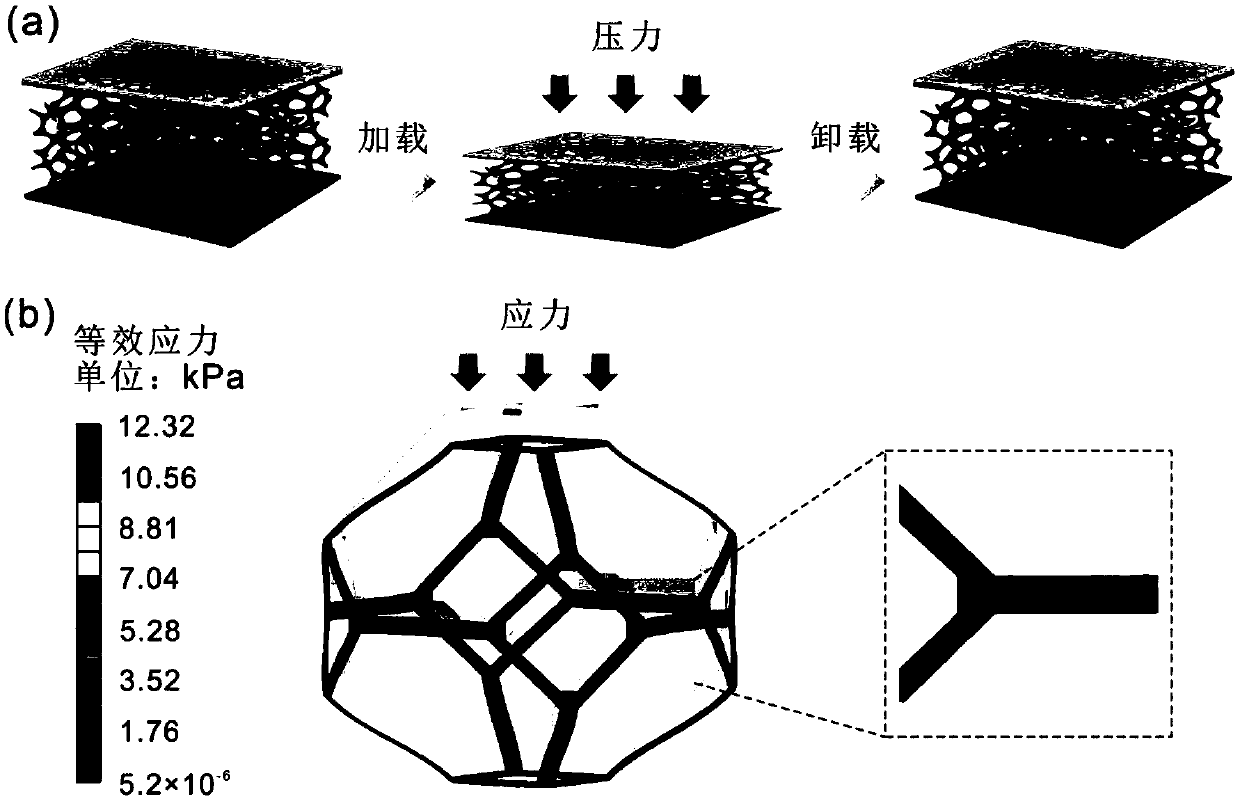

[0047] Such as figure 1 As shown, the present embodiment is based on a high-sensitivity capacitive flexible tactile sensor based on a three-dimensional porous microstructure composite dielectric layer. The upper and lower surfaces of the composite dielectric layer 4 are sequentially provided with a flexible isolation layer 3, a flexible plate 2 and a flexible protective layer 1, and the schematic diagram of its disassembly structure is shown in figure 2 shown. Among them: the flexible isolation layer 3 and the flexible protective layer 1 are made of PDMS, the flexible plate 2 is made of organic silicon conductive silver glue; the three-dimensional porous microstructure composite medium layer 4 is made of polyurethane sponge The carbon nanotube / silicone rubber conductive composite material is a force-sensitive composite material, which is obtained by impregnating and wrapping the graphene / multi-walled carbon nanotube / silicone rubber composite conductive material layer by laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com