Coarse cereal pancake premixed powder, coarse cereal pancake and preparation method thereof

A technology of premixed flour and miscellaneous grains, which is applied in the field of miscellaneous grains and noodle products. It can solve the problems of lack of production and processing technology, no preparation and research and development, and no involvement in ready-mixed flour, so as to achieve precise product formula composition, rich miscellaneous grains smell, and consistent taste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

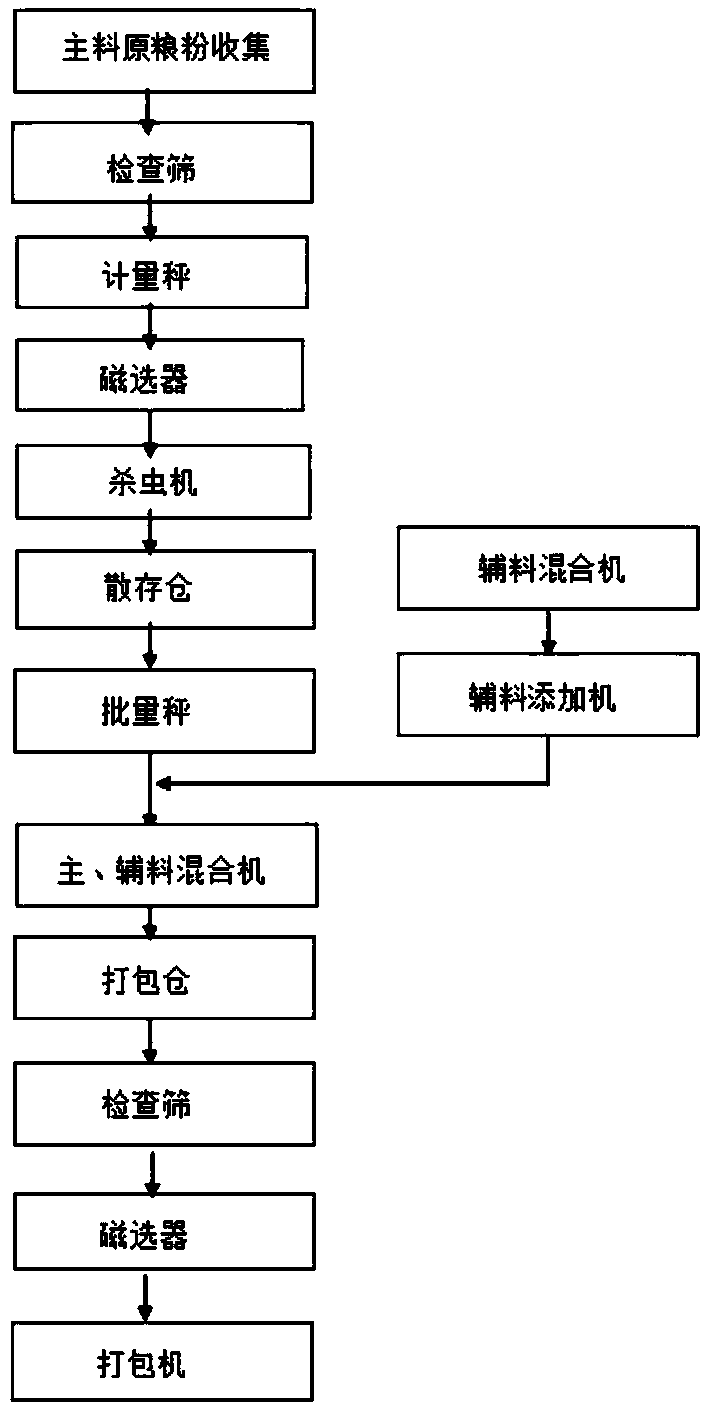

[0041] refer to figure 1 As shown, the preparation method of a kind of multigrain miscellaneous grain pancake premix powder provided by the specific embodiment of the present invention comprises the steps:

[0042] (1) According to the composition of miscellaneous grains pancake premix powder, screen and collect main materials and auxiliary materials;

[0043] (2) The main ingredients collected by screening are firstly inspected, screened, measured and magnetically separated, and then processed by an impact insecticide, and then sent to the flour bulk storage bin through positive pressure transportation;

[0044] (3) Mix the excipients collected by screening for 3-6min in proportion through the excipient mixer, and then enter the excipient addition machine;

[0045] (4) According to the required ratio of main and auxiliary materials, set the working parameters of the batch scale and screw feeding conveyor located under the bulk storage bin and auxiliary material adding machine,...

Embodiment 1

[0059] Embodiment 1: The formula of a kind of multi-cereal miscellaneous grain pancake premix powder of this embodiment: 800kg of high-gluten wheat flour, 50kg of waxy corn flour, 50kg of ordinary corn flour, 40kg of millet flour, 30kg of glutinous rice flour, 30kg of soybean flour and 5kg of salt, Edible baking soda 0.5kg, onion powder 2.5kg, garlic powder 0.25kg, black pepper powder 0.25kg, chicken powder 2.0kg.

[0060] The multigrain pancake premix powder, multigrain pancake and preparation method thereof comprise:

[0061] (1) According to the formula of the above miscellaneous grain pancake premix powder, sieve and collect raw materials;

[0062] (2) The high-gluten wheat flour, waxy corn flour, ordinary corn flour, millet flour, glutinous rice flour, and soybean flour collected by screening are firstly screened, measured and magnetically separated, and then treated by an impact insecticide machine, and then processed by normal Pressure conveying into flour bulk storage...

Embodiment 2

[0070] Embodiment 2: The formula of a kind of multi-cereal miscellaneous grain pancake premix powder of the present embodiment: 700kg of high-gluten wheat flour, 75kg of waxy corn flour, 75kg of ordinary corn flour, 60kg of millet flour, 45kg of glutinous rice flour, 45kg of soybean flour and 8kg of salt, Edible baking soda 0.8kg, onion powder 3.5kg, garlic powder 0.35kg, black pepper powder 0.35kg, chicken powder 2.8kg.

[0071] The multigrain pancake premix powder, multigrain pancake and preparation method thereof comprise:

[0072] (1) According to the formula of the above miscellaneous grain pancake premix powder, sieve and collect raw materials;

[0073] (2) The high-gluten wheat flour, waxy corn flour, ordinary corn flour, millet flour, glutinous rice flour, and soybean flour collected by screening are firstly screened, measured and magnetically separated, and then treated by an impact insecticide machine, and then processed by normal Pressure conveying into flour bulk ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com