Lower limb rehabilitation device

A lower limb, square technology, applied in the directions of gymnastics equipment, muscle training equipment, passive exercise equipment, etc., can solve serious problems such as wear and tear of exercise equipment, and achieve the effect of prolonging service life and reducing wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

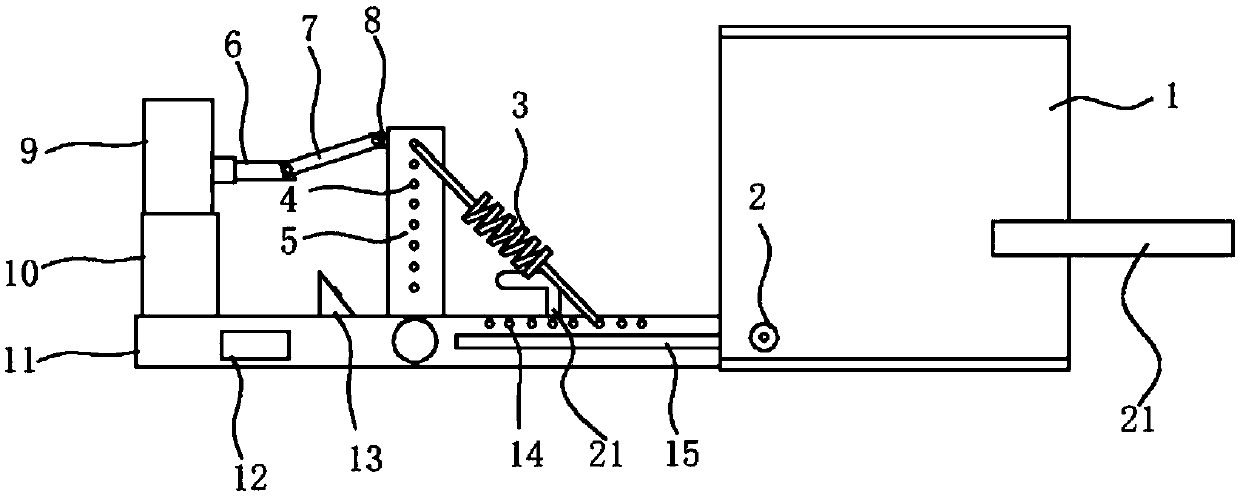

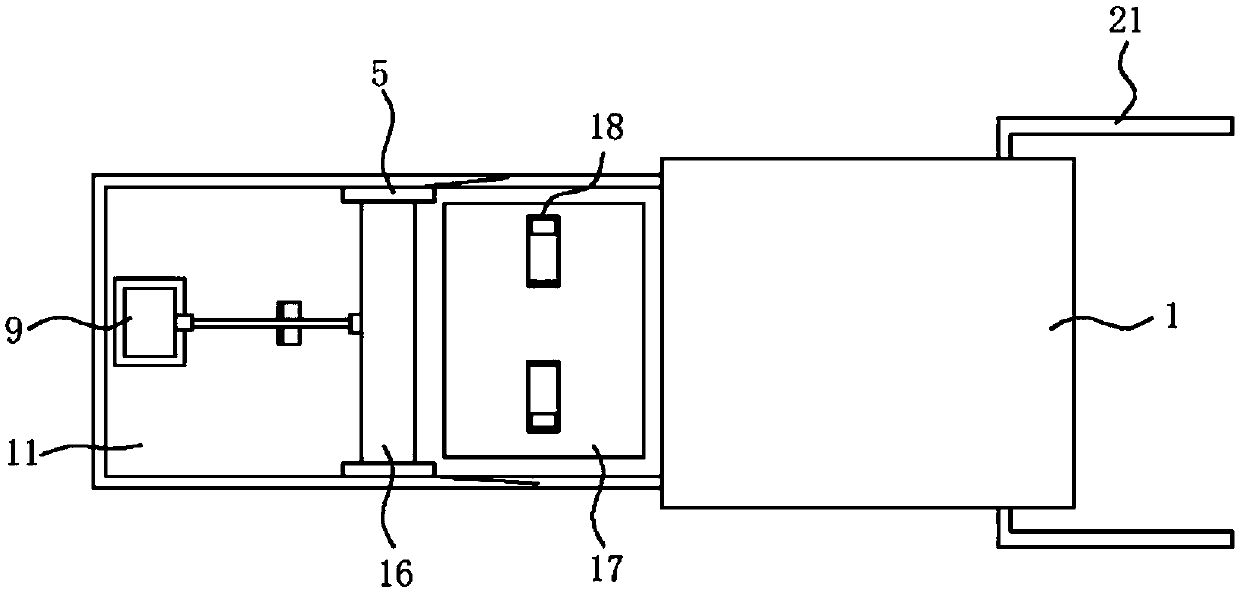

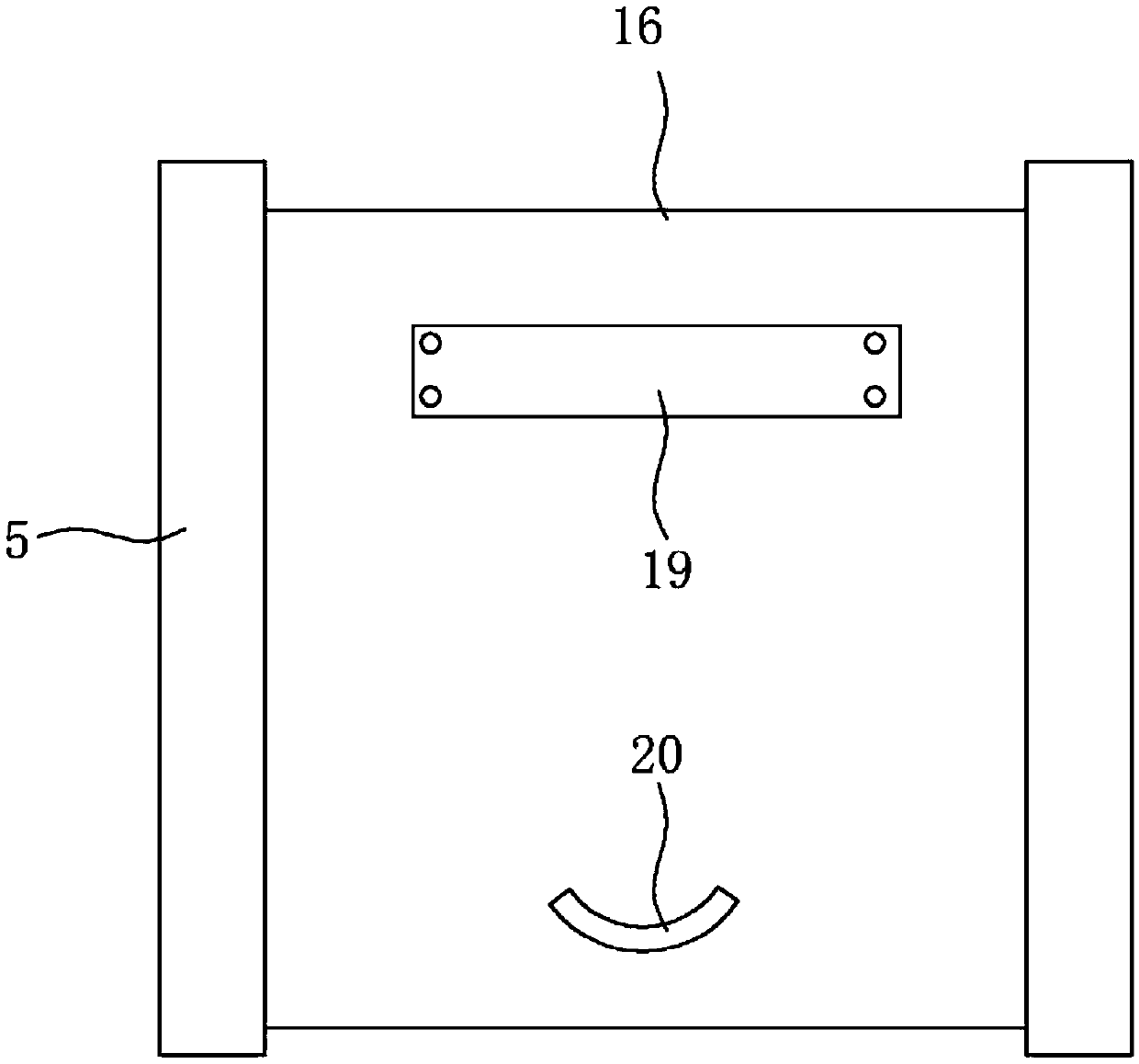

[0027] see Figure 1-3 , the present invention provides a technical solution: a lower limb rehabilitation device, comprising a square box 1, the right side of the square box 1 is provided with a square box 11, the upper end surface and the right side of the square box 11 are both Hollow surface, the upper left side of the square box body 11 is welded with a heightening block 10, the upper side of the heightening block 10 is welded with an electric cylinder 9, and the piston rod of the electric cylinder 9 is welded with a first connecting rod 6 , the front side wall and the rear side wall of the square box body 11 are hinged with a connecting plate 5, and the two connecting plates 5 before and after are directly fixedly connected with a foot fixing plate 16, and the feet fixing plate 16 The left side is welded with a second connecting rod 8, a steel rope 7 is connected between the first connecting rod 6 and the second connecting rod 8, and a limit block 13 is provided on the le...

Embodiment 2

[0037] The difference from Example 1 is that the foot fixing plate 16 is coated with a wear-resistant layer, and the preparation method of the wear-resistant layer is:

[0038] Take the following components by weight for subsequent use: 11.5 parts of polyaldehyde resin, 22.3 parts of epoxy resin, 0.9 part of titanate coupling agent, 6.1 parts of lignin fiber, 11.2 parts of sodium bentonite, 1.7 parts of propylene glycol methyl ether acetate part, 0.6 part of benzoic acid.

[0039] S1. Grinding: mix polyaldehyde resin, sodium bentonite, propylene glycol methyl ether acetate, and benzoic acid and stir evenly, and perform high-speed grinding in a ball mill until a powder with a mesh number of 40 is obtained;

[0040] S2. Prepare color paste: add epoxy resin, titanate coupling agent, and lignin fiber to the powder obtained in S1 and perform high-speed grinding until the fineness is 28 μm to obtain color paste;

[0041] S3. Preparation of wear-resistant material: heating the color...

Embodiment 3

[0046] The difference from Example 2 is that the specific gravity of the formula has been modified, and the modified formula is:

[0047] Take the following components by weight for subsequent use: 12.8 parts of polyaldehyde resin, 32.5 parts of epoxy resin, 1.4 parts of titanate coupling agent, 6.7 parts of lignin fiber, 13.6 parts of sodium bentonite, 1.9 parts of propylene glycol methyl ether acetate Parts, 1.4 parts of benzoic acid.

[0048] S1. Grinding: mix polyaldehyde resin, sodium bentonite, propylene glycol methyl ether acetate, and benzoic acid and stir evenly, and perform high-speed grinding in a ball mill until a powder with a mesh number of 40 is obtained;

[0049] S2. Prepare color paste: add epoxy resin, titanate coupling agent, and lignin fiber to the powder obtained in S1 and perform high-speed grinding until the fineness is 28 μm to obtain color paste;

[0050] S3. Preparation of wear-resistant material: heating the color paste obtained in S2 to 55° C. and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com