Nickel silicate catalyst as well as preparation method and application thereof

A catalyst, nickel-silicon technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of easy aggregation and growth, low catalytic activity, etc., to improve catalytic activity, improve low-temperature processing Hydrogen activity, the effect of overcoming poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

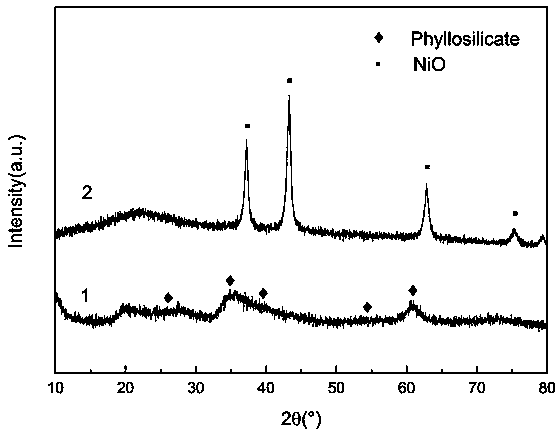

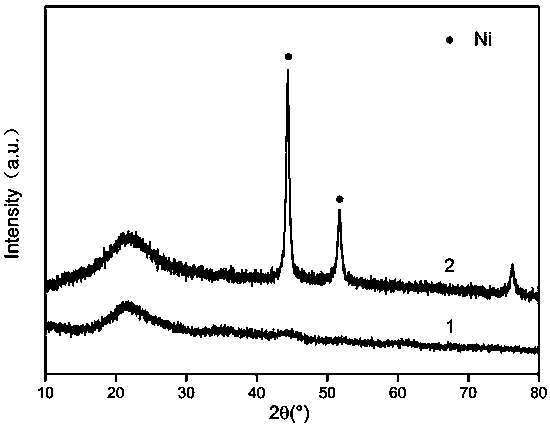

[0028] The preparation method of Ni-PS catalyst comprises the steps:

[0029] 1) At room temperature, 32 gNi(NO 3 ) 2 ·6H 2 Dissolve O in 300 ml distilled water, add 25% concentrated ammonia water (wt) dropwise to pH=11~12, and stir to make an ammonia complex solution;

[0030] 2) Add 25g of alkaline silica sol dropwise to the ammonium complex solution obtained in step 1) while stirring, continue to stir for 6 h after the dropwise addition, raise the temperature to 50 °C, and conduct uniform precipitation until the solution pH=7. The precipitate was centrifuged, washed with distilled water three times, then dried overnight at 90 °C, and then calcined at 5 °C / min to 450 °C for 4 h to make a catalyst. The mass ratio of the active metal Ni to the support was 2:3;

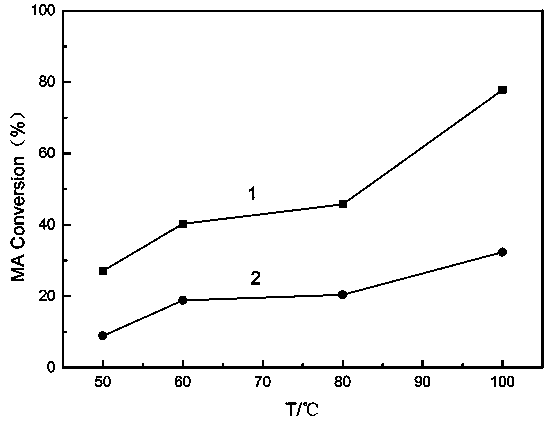

[0031] 3) Catalyst at 25V%H with a gas flow rate of 40 ml / min 2 -75V%N 2 In a mixed gas atmosphere, the temperature was raised to 400°C at 5°C / min and reduced for 2 h to obtain Catalyst A for maleic anhydride hydr...

Embodiment 2

[0033] 1) At room temperature, 20 gNi(NO 3 ) 2 ·6H 2 Dissolve O in a mixed solution of 250 ml of water and ethanol, add 25% concentrated ammonia water (wt) dropwise to pH=11~12, and stir to make an ammonia complex solution;

[0034] 2) Add 30 g of alkaline silica sol dropwise to the ammonium complex solution obtained in step 1) while stirring, continue to stir for 6 h after the dropwise addition, and raise the temperature to 60 °C for uniform precipitation until the solution pH=7 . The precipitate was centrifuged, washed with distilled water three times, then dried overnight at 100 °C, and then calcined at 550 °C for 5 h at 5 °C / min to make a catalyst. The mass ratio of the active metal Ni to the support was 1:3;

[0035] 3) Catalyst in H with a gas flow rate of 40 ml / min 2 -N 2 In a mixed gas atmosphere, the temperature was raised to 500 °C at 5 °C / min and reduced for 2 h to obtain catalyst B for maleic anhydride hydrogenation evaluation. The catalyst was added to a bat...

Embodiment 3

[0037] 1) At room temperature, 28 g Ni(NO 3 ) 2 ·6H 2 Dissolve O in 250 ml of water, add 25% concentrated ammonia water (wt) dropwise to pH=11~12, and stir to make ammonia complex solution;

[0038] 2) Add 25 g of alkaline silica sol dropwise to the ammonium complex solution obtained in step 1) while stirring, continue to stir for 10 h after the dropwise addition, and raise the temperature to 80 °C for uniform precipitation until the pH of the solution is 7 . The precipitate was centrifuged, washed with distilled water three times, then dried overnight at 80 °C, and then calcined at 5 °C / min to 600 °C for 4 h to make a catalyst. The mass ratio of the active metal Ni to the support was 1:1.78;

[0039] 3) Catalyst in H with a gas flow rate of 40 ml / min 2 -N 2 In a mixed gas atmosphere, the temperature was raised to 550 °C at 5 °C / min and reduced for 2 h to obtain catalyst C for maleic anhydride hydrogenation evaluation. The catalyst was added to a batch reactor to investi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com