Cracking sequential separation method and methanol to olefins (MTO) coupling method of naphtha and ethane

A technology of ethane cracking and sequential separation, which is applied in the direction of distillation purification/separation, hydrocarbon purification/separation, chemical instruments and methods, etc., which can solve the problems of low propylene production, large consumption of naphtha and ethane raw materials, and production and operation costs advanced questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

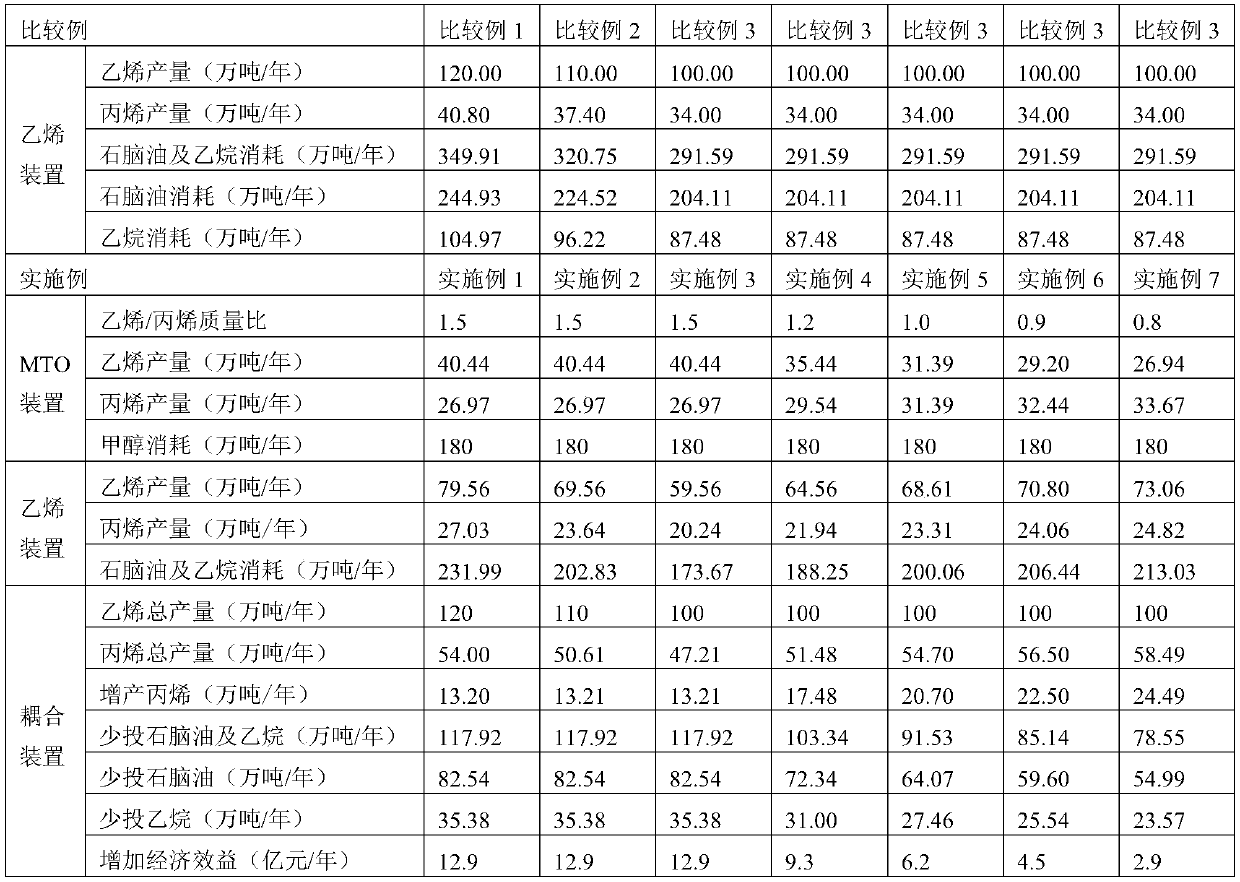

Embodiment 1

[0020] Adopt the method of a kind of naphtha and ethane cracking sequence separation and MTO coupling of the present invention, technological process is as follows: Ethylene device: Cracking raw material naphtha and ethane enter cracking furnace to generate steam thermal cracking reaction to generate materials such as ethylene, propylene, The high-temperature cracked gas at the outlet of the cracking furnace enters the quenching zone for quenching treatment, and then is sent to the compression zone for pressurization; the recombined cracking gasoline and cracking fuel oil separated in the quenching zone; the pressurized cracking gas material is combined with the material from the MTO unit After that, it is sent to the demethanizer, and methane and hydrogen are separated from the top of the tower, and the C2 and components above C2 separated from the tower are sent to the deethanizer; the C2 material is separated from the top of the deethanizer, and the material is sent to the et...

Embodiment 2

[0025] Only the nominal capacity of the ethylene unit is changed to 1.1 million tons / year, and the rest of the conditions and steps are exactly the same as in [Example 1]. The propylene production capacity of the coupling device is 506,100 tons / year. Compared with [Comparative Example 2], the propylene production is increased by 132,100 tons / year, 825,400 tons / year of naphtha is reduced, and 353,800 tons / year of ethane is reduced. The price difference between products and raw materials can save 1.29 billion yuan per year.

Embodiment 3

[0029] Only the nominal capacity of the ethylene plant is changed to 1 million tons / year, and the rest of the conditions and steps are exactly the same as in [Example 1]. The propylene production capacity of the coupling device is 472,100 tons / year. Compared with [Comparative Example 3], the propylene production is increased by 132,100 tons / year, 825,400 tons / year of naphtha is reduced, and 353,800 tons / year of ethane is reduced. The price difference between products and raw materials can save 1.29 billion yuan per year.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com