Beta-lactoglobulin-vitamin conjugate comprising sugar alcohols and preparation method thereof

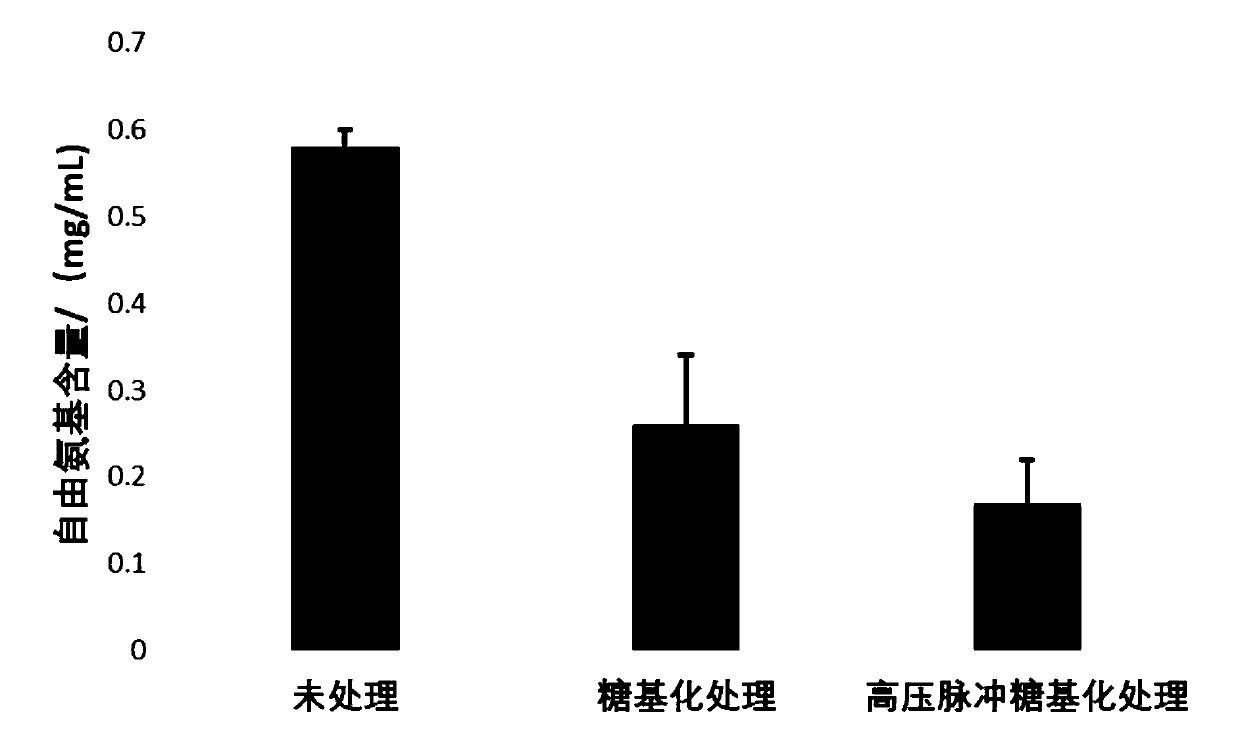

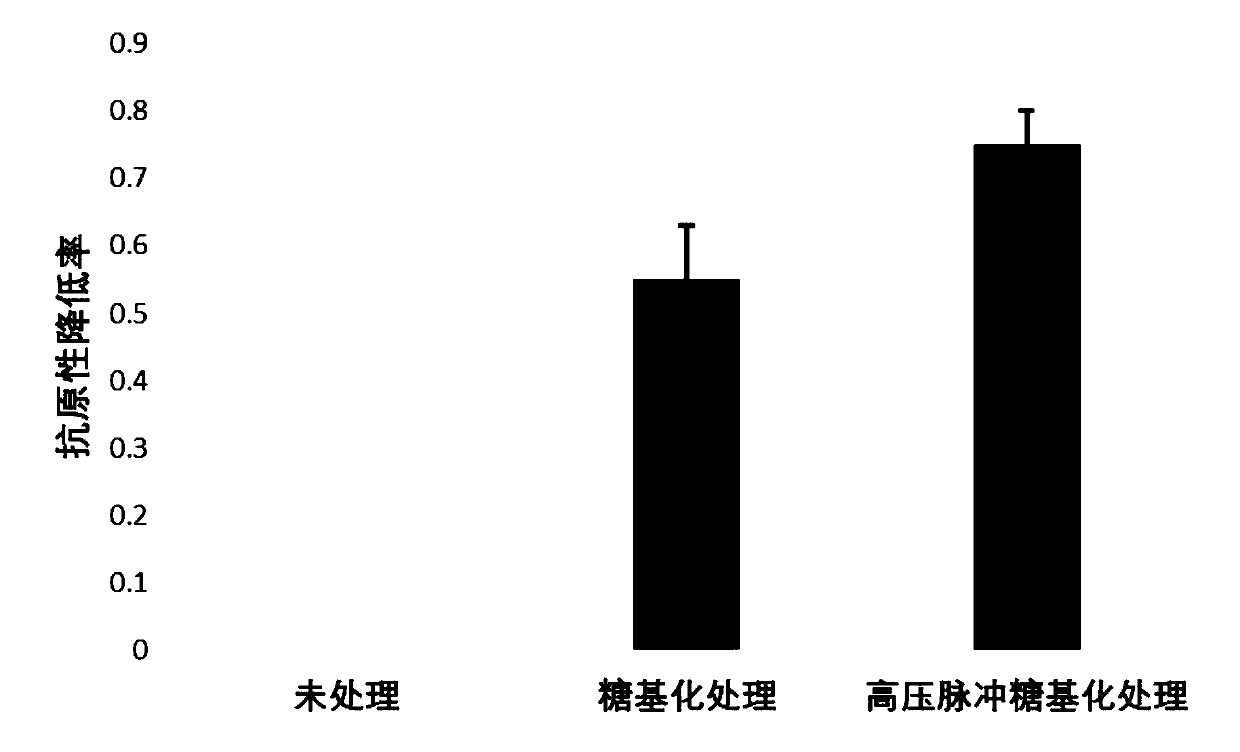

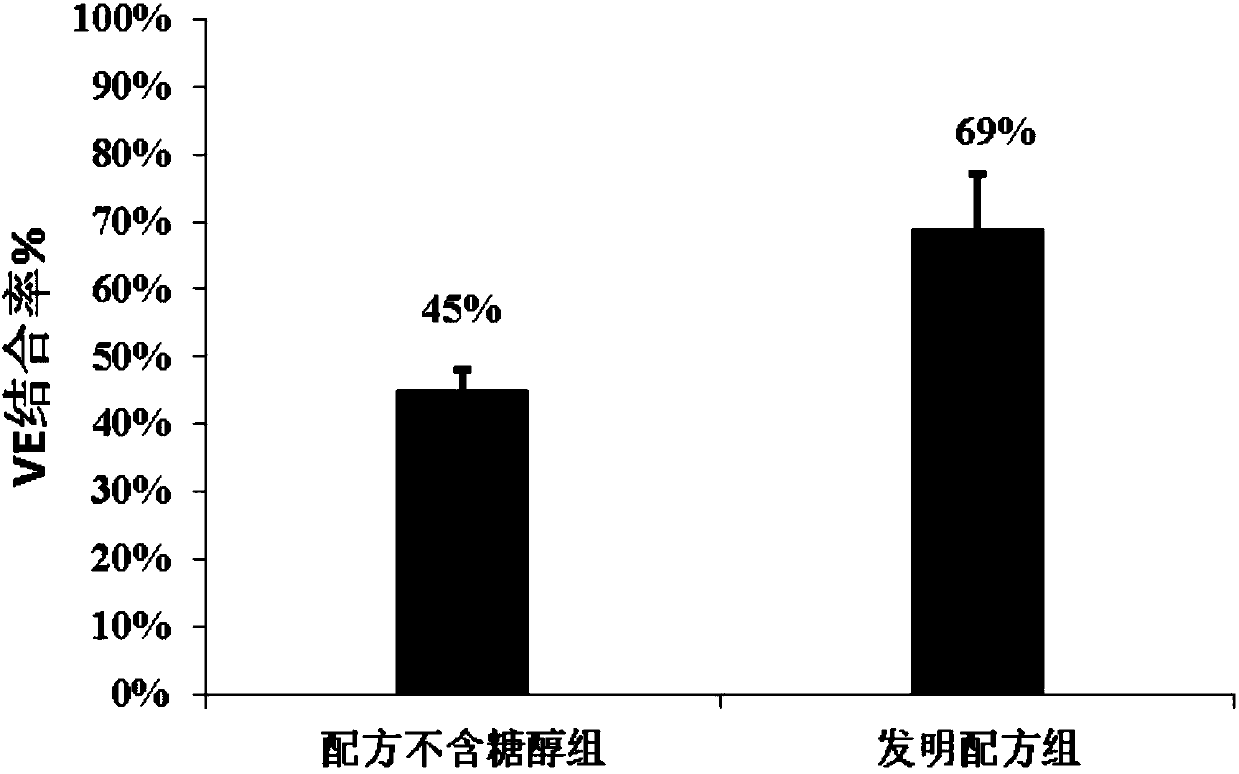

A lactoglobulin and vitamin technology, which is applied in the biological field, can solve the problems of reduced assembly effect, limited application surface, and β-lactoglobulin sensitization is not eliminated, and achieves the effect of improving the binding rate and reducing the sensitization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention also discloses a preparation method of the aforementioned sugar alcohol-containing β-lactoglobulin-vitamin conjugate, which comprises the following steps:

[0032] Step 1. The β-lactoglobulin is made into a 1mg / mL β-lactoglobulin solution with 0.01mol / L pH7.4 phosphate buffer solution.

[0033] Step two, place the β-lactoglobulin solution in a high-voltage electric field for high-voltage pulse treatment.

[0034] Step 3: Combine β-lactoglobulin after high-pressure pulse glycosylation with VE, sorbitol, and maltitol, and then freeze-dry the composition to obtain dry β-lactoglobulin containing sugar alcohol Vitamin conjugate products.

[0035] In step 2, the β-lactoglobulin solution is placed in a high-voltage electric field for a processing time of 80 μs, wherein the electric field intensity of the high-voltage electric field is 30 kV / cm, and the electric field waveform is a unipolar square wave.

[0036] In step three, the combination method includes: weighing β-la...

Embodiment 1

[0044] The first preparation method of β-lactoglobulin-vitamin conjugate containing sugar alcohol of the present invention includes the following steps:

[0045] (11) The β-lactoglobulin is made into a 1mg / mL β-lactoglobulin solution with 0.01mol / L, pH7.4 phosphate buffer solution.

[0046] (12) Put the β-lactoglobulin solution in a high-voltage electric field with an electric field strength of 30kV / cm and a unipolar square wave for 80μs.

[0047] (13). Mix the β-lactoglobulin with VE, sorbitol, and maltitol obtained in step (12) at a mass ratio of 1:0.01:2, and then freeze-dry it. Put the freeze-dried powder in a centrifuge tube and put it in an incubator. React in a 59% saturated potassium iodide solution with a temperature of 65°C and a relative humidity of 65% by mass for 3 hours. After the reaction, the centrifuge tube is immediately placed in an ice bath. Terminate the reaction. After the reaction is over, add pre-cooled ultrapure water for reconstitution, and then use an ultr...

Embodiment 2

[0050] The second preparation method of the β-lactoglobulin-vitamin conjugate containing sugar alcohol of the present invention includes the following steps:

[0051] (21) The β-lactoglobulin is made into a 1mg / mL β-lactoglobulin solution with 0.01mol / L, pH7.4 phosphate buffer solution.

[0052] (22) Place the β-lactoglobulin solution in a high-voltage electric field with an electric field strength of 30kV / cm and a unipolar square wave for 80μs.

[0053] (23). Mix the β-lactoglobulin with VE, sorbitol, and maltitol in a mass ratio of 1:0.01:2, and then freeze-dry the β-lactoglobulin after the first-level high-pressure pulse glycosylation in step (22). Put the freeze-dried powder in a centrifuge tube and put it in an incubator, and react in a 59% saturated potassium iodide solution with a temperature of 65°C and a relative humidity of 65% by mass for 3 hours. After the reaction, the centrifuge tube is immediately placed in an ice bath Terminate the reaction. After the reaction is ove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com