Nylon composite material, and preparation method and application thereof

A nylon composite material, nylon technology, applied in the direction of offensive equipment, fireproof coatings, coatings, etc., can solve the problems of unsatisfactory appearance quality, hot hand of the rifle hand guard, etc., and achieve the color of the outer surface without fading , The color of the outer surface is beautiful, and the effect of improving the heat insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057]

[0058] A kind of preparation method of above-mentioned nylon composite material, it comprises the steps:

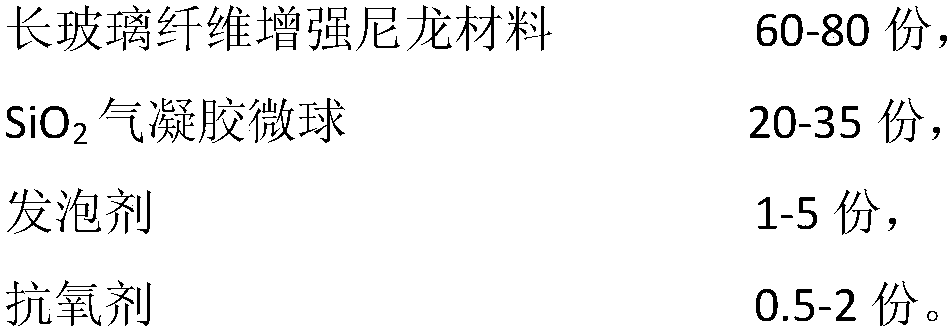

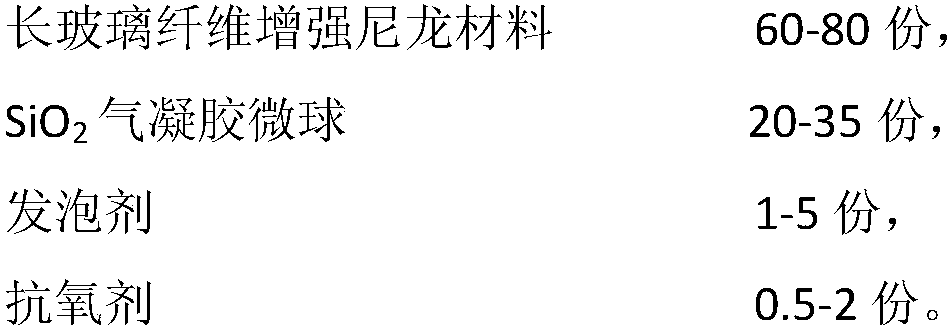

[0059] (1), 60-80 parts of long glass fiber reinforced nylon materials are dried to obtain dry long glass fiber reinforced nylon materials;

[0060] (2), dry long glass fiber reinforced nylon material, 20-35 parts of SiO 2 Airgel microspheres, 1-5 parts of foaming agent and 0.5-2 parts of antioxidant are mixed evenly, and stirred to obtain a mixture;

[0061] (3) Add the mixture into a twin-screw extruder to melt and extrude it, and then stretch it, cool it, dry it, and cut it into pellets to obtain a nylon composite material.

[0062] Wherein, in step (1), the moisture content of the long glass fiber reinforced nylon material can be 1.5-2%, preferably 1.5%; the drying temperature can be 80-100°C, preferably 80°C; the drying time can be 8- 12h, preferably 12h.

[0063] In step (3), the temperature of the twin-screw extruder is 275-330°C, and the extrusion ra...

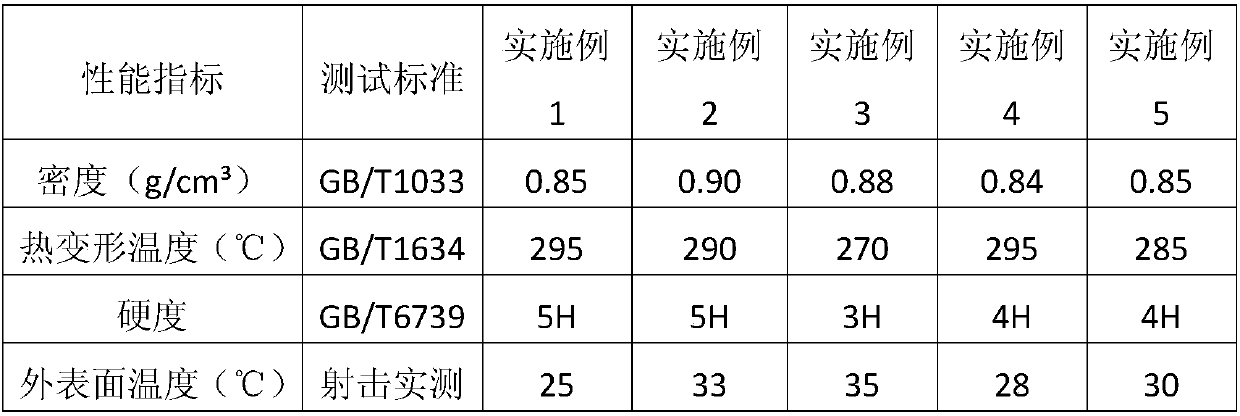

Embodiment 1

[0078] The preparation method of the rifle handguard of the present embodiment comprises the steps:

[0079] (1), 60 parts of long glass fiber reinforced polyhexamethylene terephthalamide (PA6T) materials (moisture content 1.5%) with a long glass fiber content of 50wt% were dried at 80°C for 12h to obtain dried Long glass fiber reinforced polyhexamethylene terephthalamide (PA6T) material;

[0080] (2), dry long glass fiber reinforced polyhexamethylene terephthalamide (PA6T) material, 35 parts of SiO 2 Airgel microspheres (particle size is 20μm, porosity is 90%, density is 0.29g / cm 3 ), 1 part of p-toluenesulfonylsemicarbazide TSSC (as foaming agent) and 1 part of antioxidant 168 are mixed uniformly in a high-speed mixer, and stirred to obtain a mixture;

[0081] (3) Add the mixture to a twin-screw extruder for melt extrusion, and then stretch, cool, dry, and pelletize to obtain a nylon composite material; wherein, the temperature in each zone from the feeding port to the mac...

Embodiment 2

[0093] The preparation method of the rifle handguard of the present embodiment comprises the steps:

[0094] (1), 70 parts of long glass fiber reinforced polynonanediamine terephthalamide (PA9T) materials (moisture content 2%) with a long glass fiber content of 40wt% were dried at 90°C for 10h to obtain dried Long glass fiber reinforced polynonanediamine terephthalamide (PA9T) material;

[0095] (2), dry long glass fiber reinforced polynonanediamine terephthalamide (PA9T) material, 30 parts of SiO 2 Airgel microspheres (particle size is 40μm, porosity is 95%, density is 0.25g / cm 3 ), 2 parts of p-toluenesulfonyl semicarbazide TSSC (as blowing agent) and 0.5 part of antioxidant 1010 are mixed uniformly in a high-speed mixer, and stirred to obtain a mixture;

[0096](3) Add the mixture to a twin-screw extruder for melt extrusion, and then stretch, cool, dry, and pelletize to obtain a nylon composite material; wherein, the temperature in each zone from the feeding port to the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com