Sand-containing colorful stone paint and preparation method thereof

A technology of colorful imitation stone coatings and coatings, applied in the field of architectural coatings, can solve the problems of poor simulation, poor flexibility and vividness of color dots, and achieve the effect of good storage stability and clear color dots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

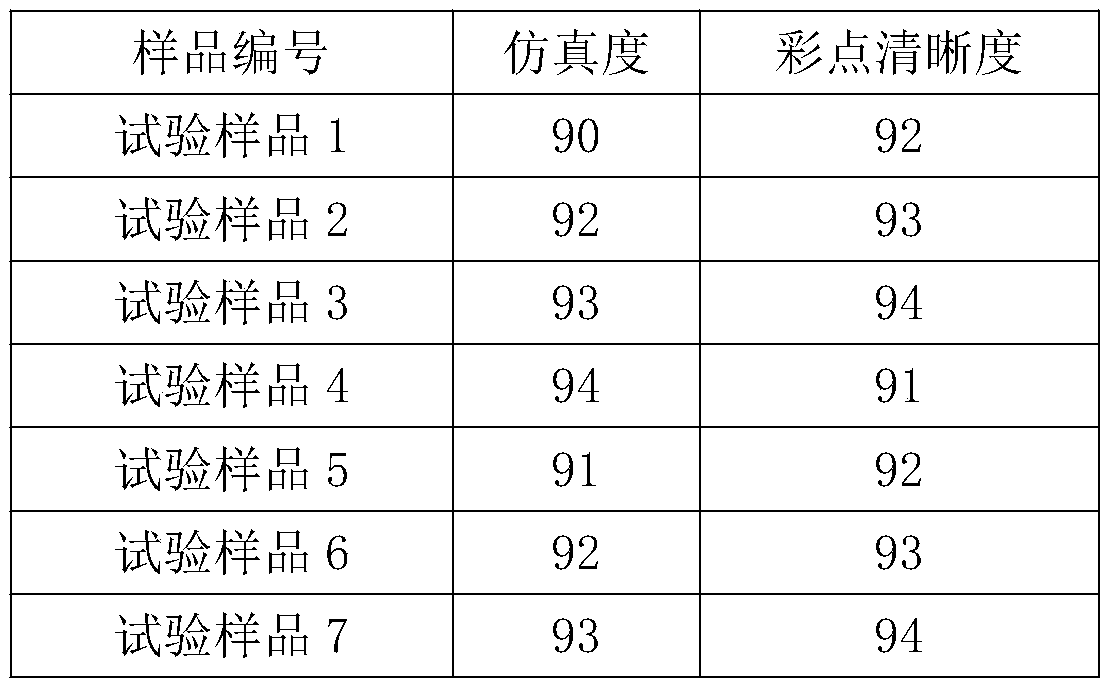

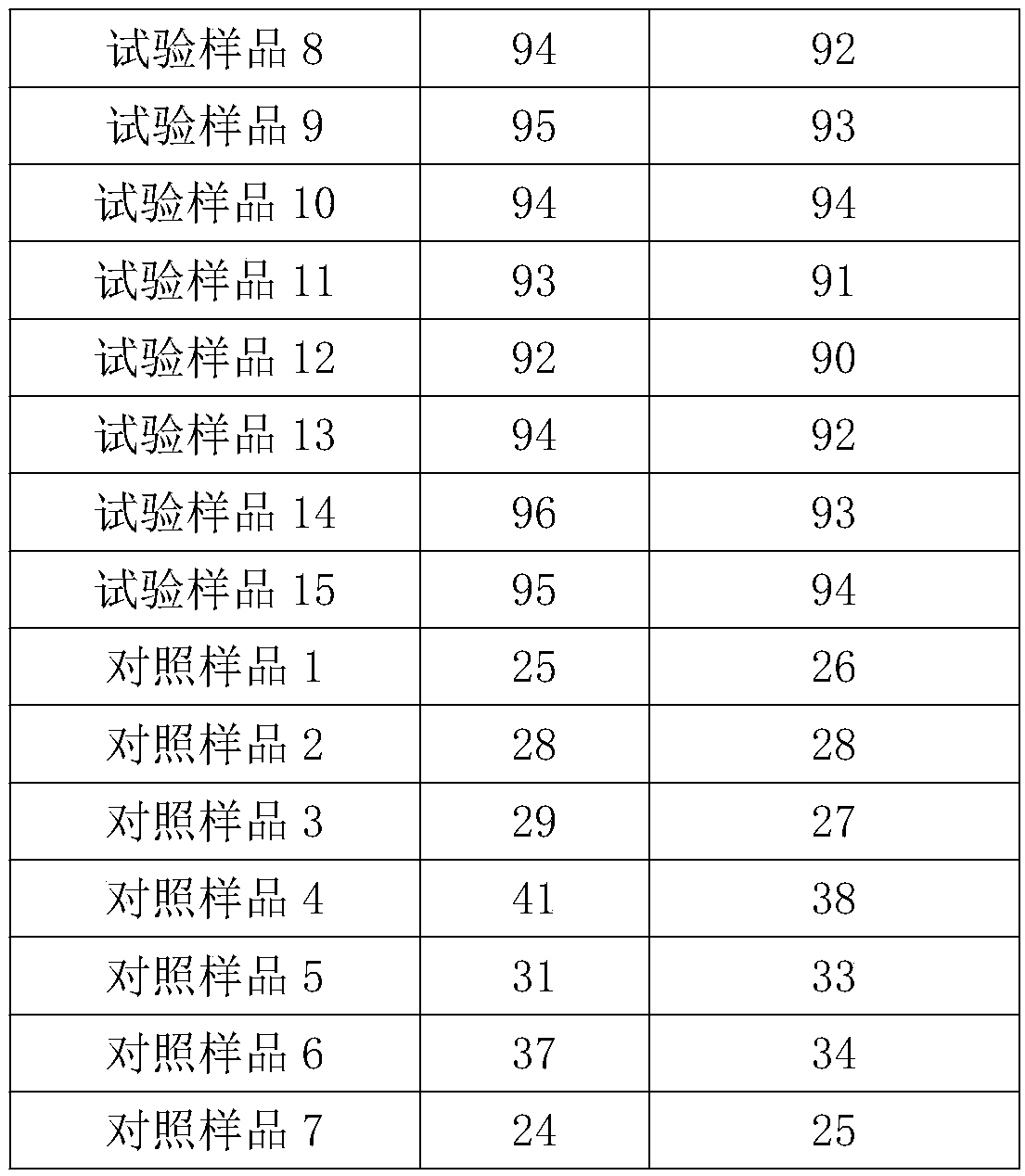

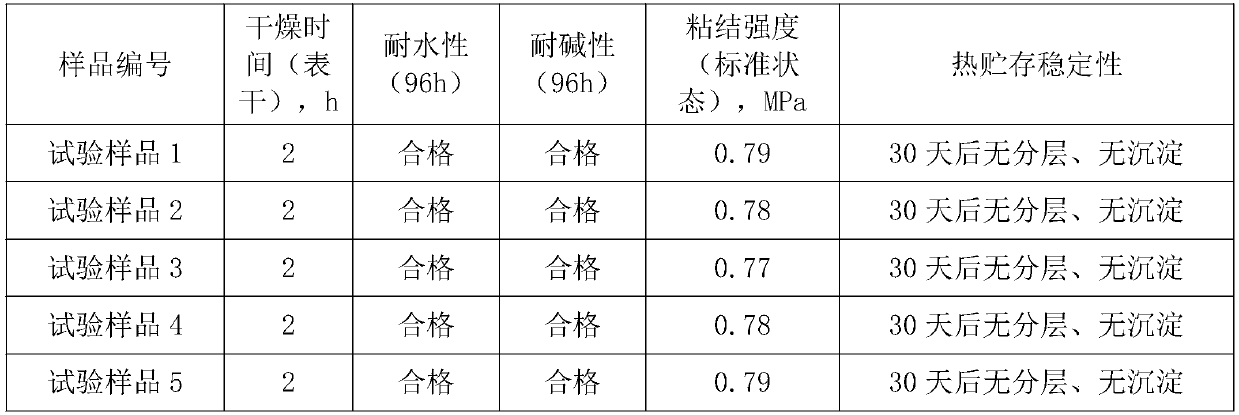

Examples

Embodiment 1

[0063]Embodiment 1: a kind of preparation method of sand-containing colorful imitation stone coating comprises the following steps:

[0064] Step 1, prepare pre-gel, mix preservative, magnesium aluminum silicate, water, and disperse for 60 minutes at a speed of 1500 rpm to obtain pre-gel, which includes the following components in weight percentage: preservative 0.1%; magnesium aluminum silicate 6%; the balance is water, and the main component of the preservative is Kathon.

[0065] Step 2, prepare the base paint, mix the hydrophobically modified cellulose, defoamer, wetting agent, film-forming aid, filler, and water and disperse evenly, the dispersion speed is 1700 rpm, and the dispersion time is 25 minutes. When the dispersion speed drops to 400 rpm, add multifunctional amine additives, preservatives, and acrylic emulsion to disperse evenly. The dispersion time is 6 minutes, and then slowly add pregel to disperse evenly. The dispersion speed is 850 rpm. 12 minutes to obtain...

Embodiment 2

[0085] Embodiment 2: A kind of preparation method of sand-containing colorful imitation stone paint, the difference with embodiment 1 is that pre-gel comprises the following components in weight percentage: preservative 0.2%; Magnesium aluminum silicate 8%; The amount is water.

Embodiment 3

[0086] Embodiment 3: A kind of preparation method of sand-containing colorful stone imitation paint, the difference with embodiment 1 is that pre-gel comprises the following components by weight percentage: preservative 0.3%; Magnesium aluminum silicate 10%; The amount is water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com