Hot melt polyurethane adhesive for water-repellent fabric lamination and preparation method thereof

A hot-melt polyurethane and water-repellent technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problem of low surface energy, achieve low viscosity, low operating temperature, and good glass transition temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

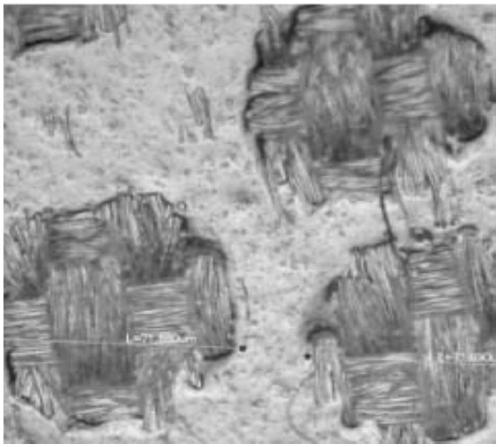

Image

Examples

preparation example Construction

[0038] In addition, the present invention also provides a kind of preparation method of described hot-melt polyurethane adhesive, comprises the following steps:

[0039] 1) Put silicon-containing polyol, fluorocarbon-containing polyol and dimer acid in a molar ratio of 1:1.05 (adjustable according to demand), place them in a reaction kettle, heat to 210-240°C under nitrogen protection, and dehydrate for 16 - About 18 hours until the acid value is less than 0.6; during the reaction, nitrogen protection and high vacuum are used to dehydrate quickly. After the reaction is completed, the material is discharged in a molten state for use, and the state of the product is a highly viscous liquid (or a lower melting point. solid), its molecular weight of polymer among the present invention is between 3000-4500, is called for short AFS-X;

[0040] 2) Add AFS-X, polycaprolactone, wetting agent and antioxidant prepared in step 1) into the reactor, heat and dissolve to a uniform state, the...

Embodiment 1

[0042] A preparation method of hot-melt polyurethane adhesive, comprising the following steps:

[0043] 1) Put silicon-containing polyol, fluorocarbon-containing polyol and dimer acid in a molar ratio of 1:1.05 (adjustable according to requirements), place them in a reaction kettle, heat to 210°C under nitrogen protection, and dehydrate for about 18 hours Until the acid value is less than 0.6; during the reaction, nitrogen protection is utilized and a high vacuum is used so as to dehydrate quickly. After the reaction is completed, it is discharged in a molten state for use, and the state of the product is a highly viscous liquid (or a solid with a lower melting point). The molecular weight of the polymer in the present invention is between 3000-4500, referred to as AFS-X;

[0044] 2) Add AFS-X, polycaprolactone, wetting agent and antioxidant prepared in step 1) into the reactor, heat and dissolve to a uniform state, then vacuum dehydrate for 45min, add diisocyanate at 80°C to ...

Embodiment 3

[0055] Comparative Examples.

[0056] The preparation method of the hot-melt polyurethane adhesive comprises the following steps: adding common polyether, polycaprolactone, wetting agent and anti-aging agent into a reactor, heating and dissolving to a homogeneous state, and then vacuum dehydrating for 45min, at 80°C Add diisocyanate and keep it reacting at 100°C for 4 hours, take a sample to test that the viscosity value and NCO value are less than the theoretical value, and finally vacuum defoam and pack.

[0057] The amount of each component used is shown in Table 3 below.

[0058] Table 3 is each component consumption in embodiment 3

[0059]

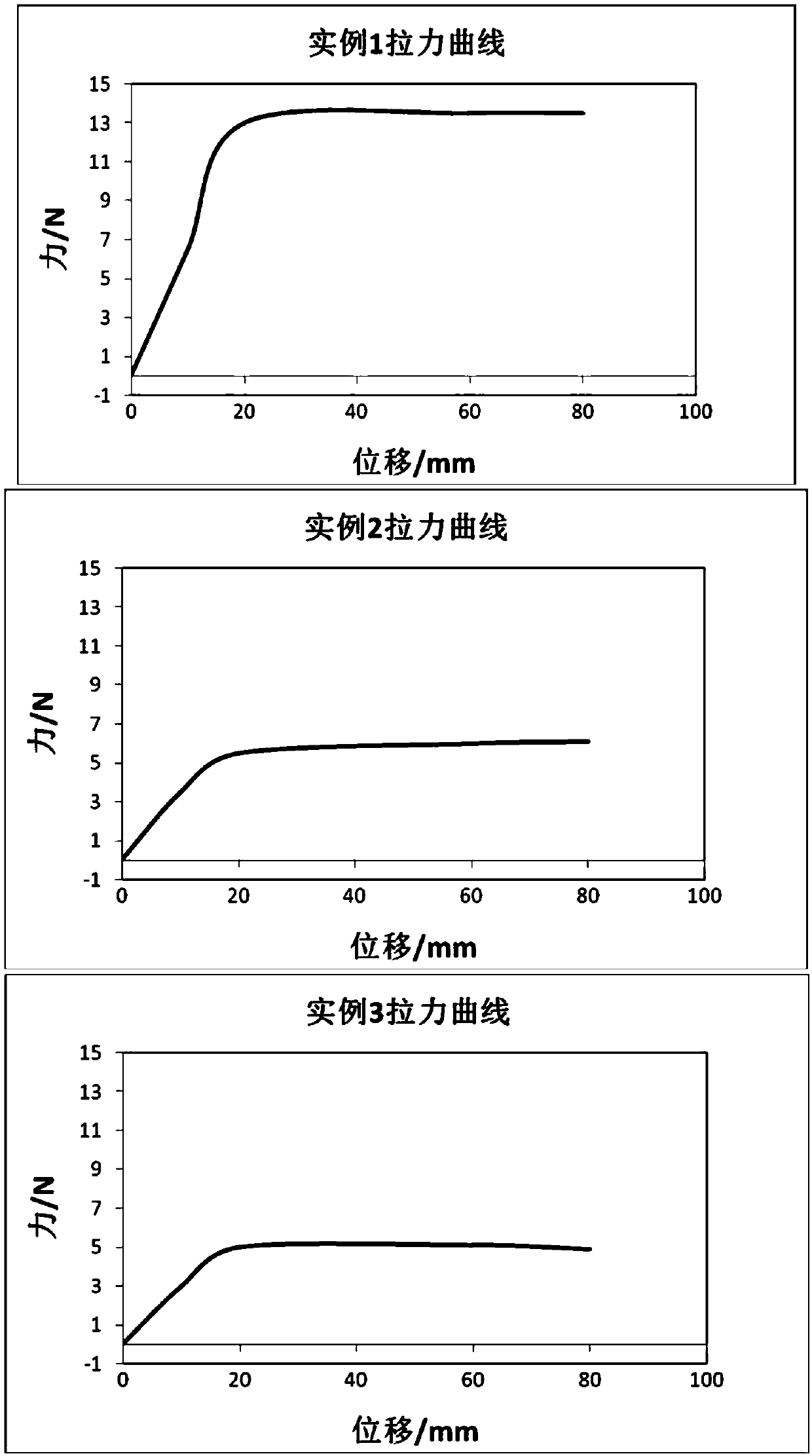

[0060] The performance results of the above-mentioned embodiments are shown in Table 4 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com