Method for producing gentian oligosaccharides by immobilized beta-glucosidase

A technology of glucosidase and gentian oligosaccharide is applied in the field of immobilized beta-glucosidase to produce gentian oligosaccharide, and can solve the problems of unseen industrialized production and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: Optimization of high-density fermentation conditions in a 3.6L tank of recombinant Pichia pastoris

[0032]The previously constructed recombinant strain P. pastoris KM71 / pPIC9K-bgl1 / pPICZ-A-pdi was used as the starting strain. For the strain construction method, see Preparation of Gentiooligosaccharides Using Trichoderma Virideβ-Glucosidase, F Wang, Food Chemistry, 2018, 248: 340- 345, carried out scale-up culture on a 3.6L tank, and optimized the fermentation process conditions from the three aspects of induction temperature, initial induction cell concentration and methanol concentration in the induction stage, so as to realize the expression of Trichoderma virideβ-glucosidase in recombinant Pichia pastoris efficient expression. The specific optimization process is as follows:

[0033] The seed culture solution is inserted into the fermentation medium at a ratio of 10%, cultivated to a certain extent under the conditions of a temperature of 30° C., a disso...

Embodiment 2

[0038] Embodiment 2: Preparation of immobilized β-glucosidase

[0039] The specific technical scheme is as follows:

[0040] (1) Using the recombinant Pichia pastoris (P.pastoris KM71 / pPIC9K-bgl1 / pPICZ-A-pdi) constructed in the laboratory as the starting strain, prepare the β-glucosidase enzyme solution;

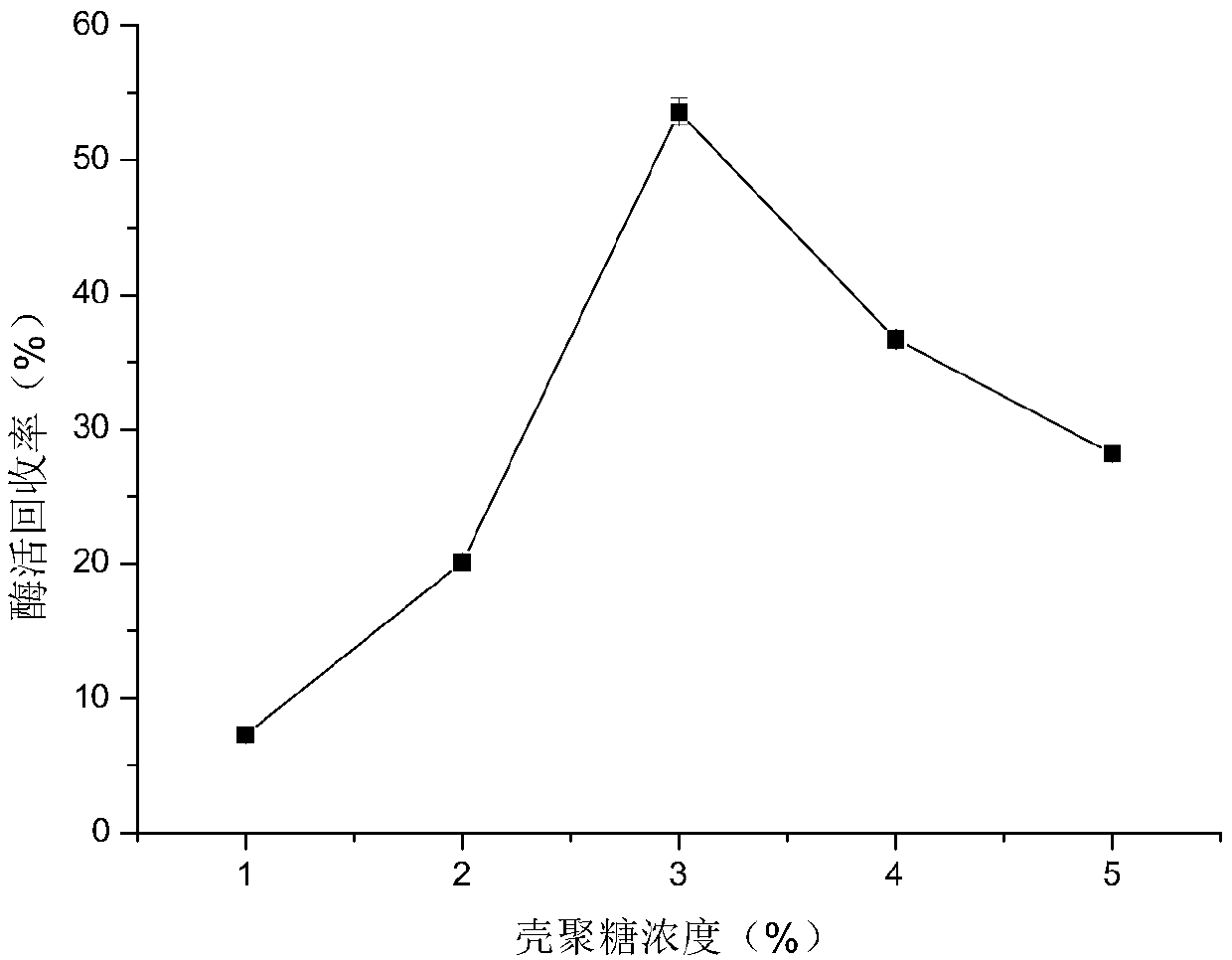

[0041] (2) dissolving chitosan in 2.0% acetic acid solution, making the chitosan concentration reach 1.0-5.0%, making chitosan colloidal solution;

[0042] (3) drop the colloid solution obtained in 2) into 4mol / L sodium hydroxide solution at a speed of 40-60 drops / min with a syringe with a needle to form chitosan microspheres of uniform size, and then use deionized Wash to neutral;

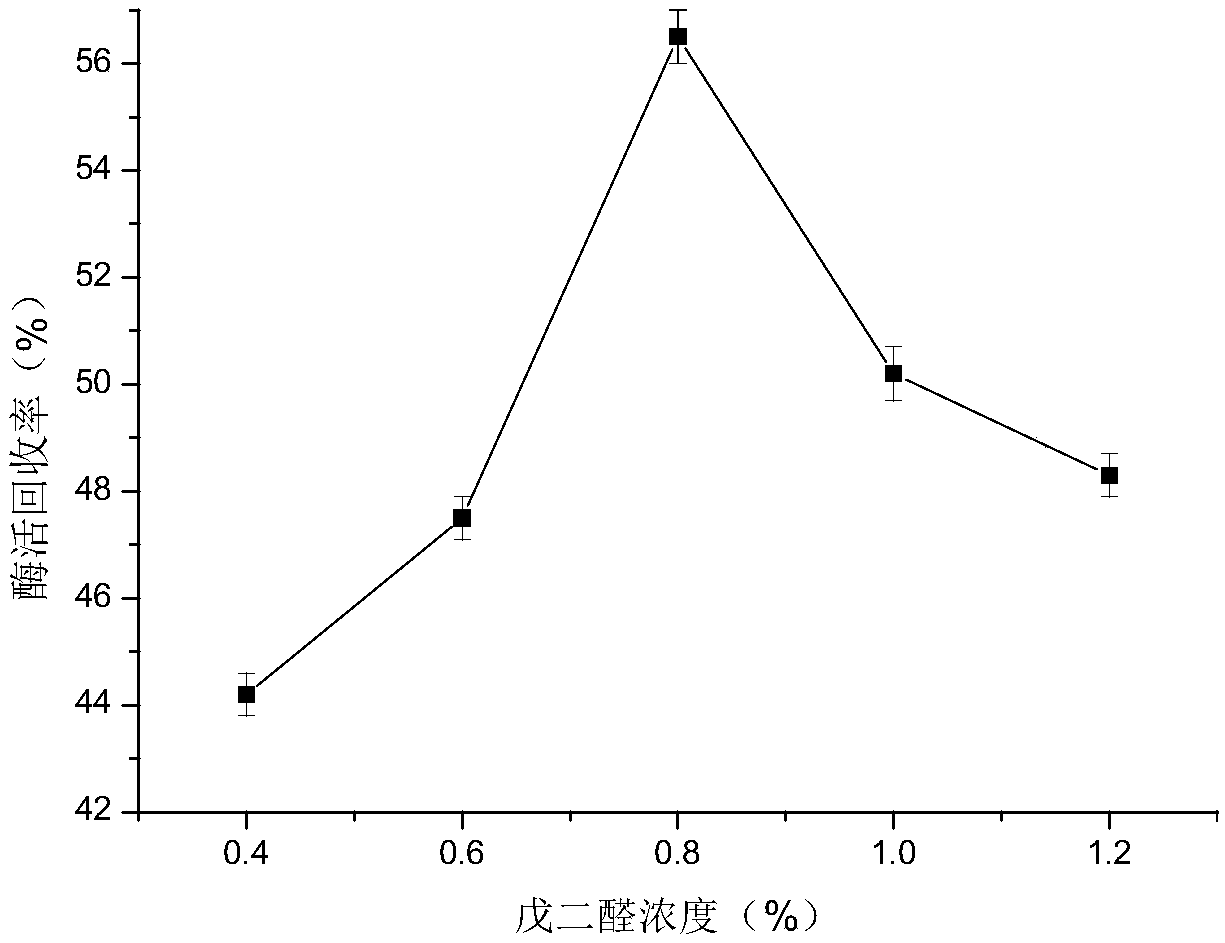

[0043] (4) Add the chitosan microspheres that have been washed to neutrality into an aqueous glutaraldehyde solution with a volume concentration of 0.4%-1.2%, cross-link at 4°C for 2 hours, pour off the glutaraldehyde solution, and wash away with deionized water. excess glutaraldehyde.

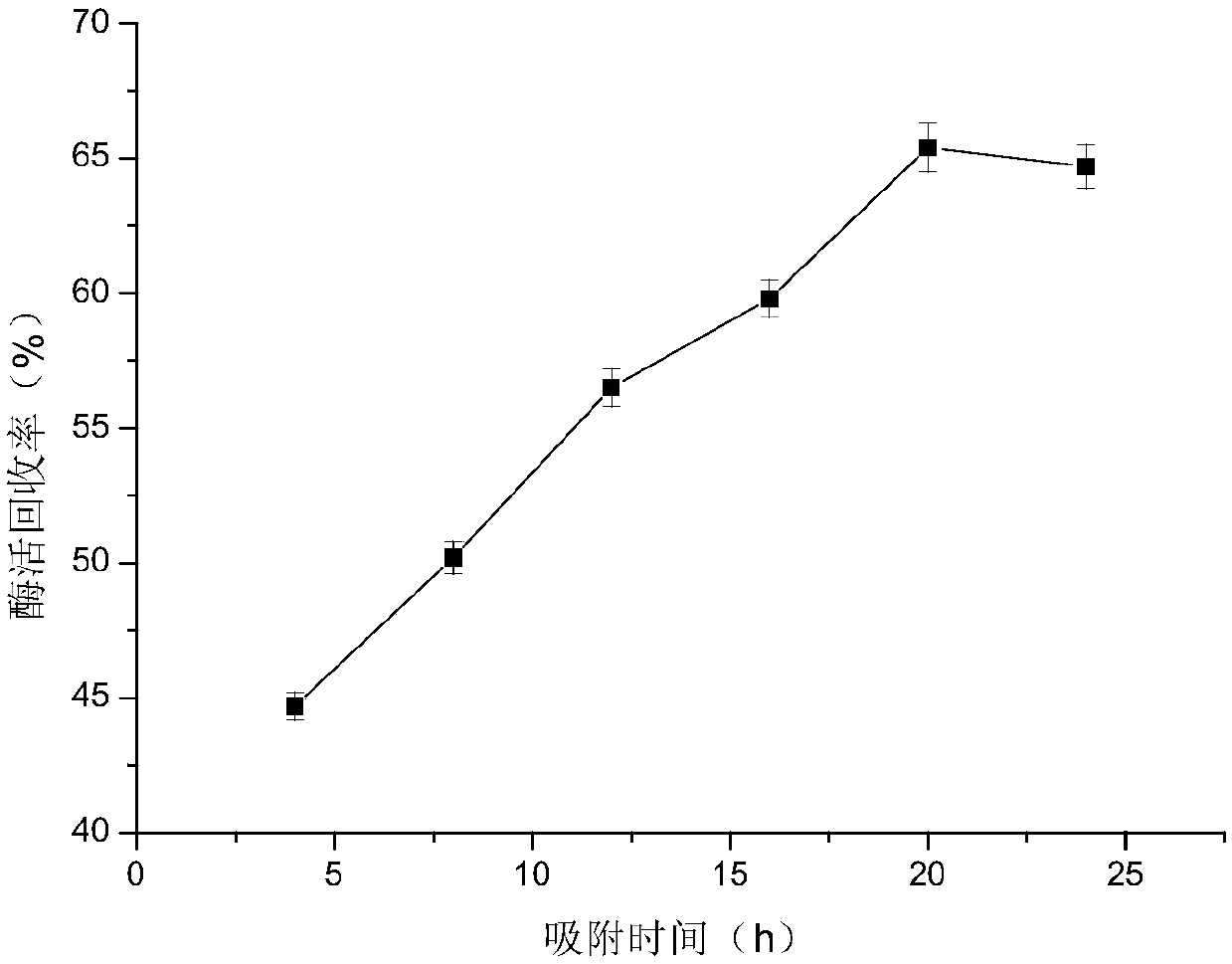

[00...

Embodiment 3

[0046] Example 3: Conversion of immobilized β-glucosidase to produce gentiooligosaccharides

[0047] The immobilized enzyme was converted 6 times continuously, and the yield of gentiooligosaccharide was detected after each time. Specifically, the enzymatic conversion was carried out at pH 5.0, 60°C, with 20% glucose and 40% cellobiose as substrates, the amount of enzyme added was 400U / g cellobiose, and the reaction was terminated after 48 hours of reaction, and the immobilized enzyme Filter out of it. The content of gentiooligosaccharides in the reaction solution is detected, the yield of gentiooligosaccharides is calculated, and then the immobilized enzyme is put back into fresh substrates to catalyze the reaction. The results showed that with the increase of conversion times, the yield of gentiooligosaccharides (the ratio of actual yield to theoretical yield) gradually decreased, and the yield of gentiooligosaccharides at the sixth continuous conversion was still 15.2%. It...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com