Bonding process for target material for liquid crystal display, semiconductor and electronics

A liquid crystal display and semiconductor technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of inability to create a working environment for workers and high working environment temperature, reduce energy consumption and reduce oxidation degree, the effect of reducing the ambient temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A bonding process of targets for liquid crystal displays, semiconductors, and electronics in this embodiment uses pure copper as the target and back plate. The purity of pure copper reaches 99.99%. The target size is 1350mm*250mm, and Board size: 1400mm*300mm. The bonding process includes the following steps:

[0024] Step 1, preparation of bonding material pure metal indium wire

[0025] Use sandpaper to polish the surface of the bonding material indium wire for 3 minutes, and there is no oxidation, rust and other impurities on the surface. The indium wire has a purity of 99.99%, a diameter of φ10.6mm, and is put into the melting machine straightly.

[0026] Step two, grinding operation

[0027] Grind the bonding surface required for the target and the back plate. For the first grinding, use 320# sandpaper to grind the target and the back plate for 3 to 5 minutes, and then use 150# sandpaper to grind the bonding surface of the target and the back plate for 3 to 5 mi...

Embodiment 2

[0042] The difference from the first embodiment is that the following parameters of the bonding process of a liquid crystal display, semiconductor, and electronic targets in this embodiment are different.

[0043] In Step 4, the injection rate is 10 m / min, and the injection temperature is 180°C.

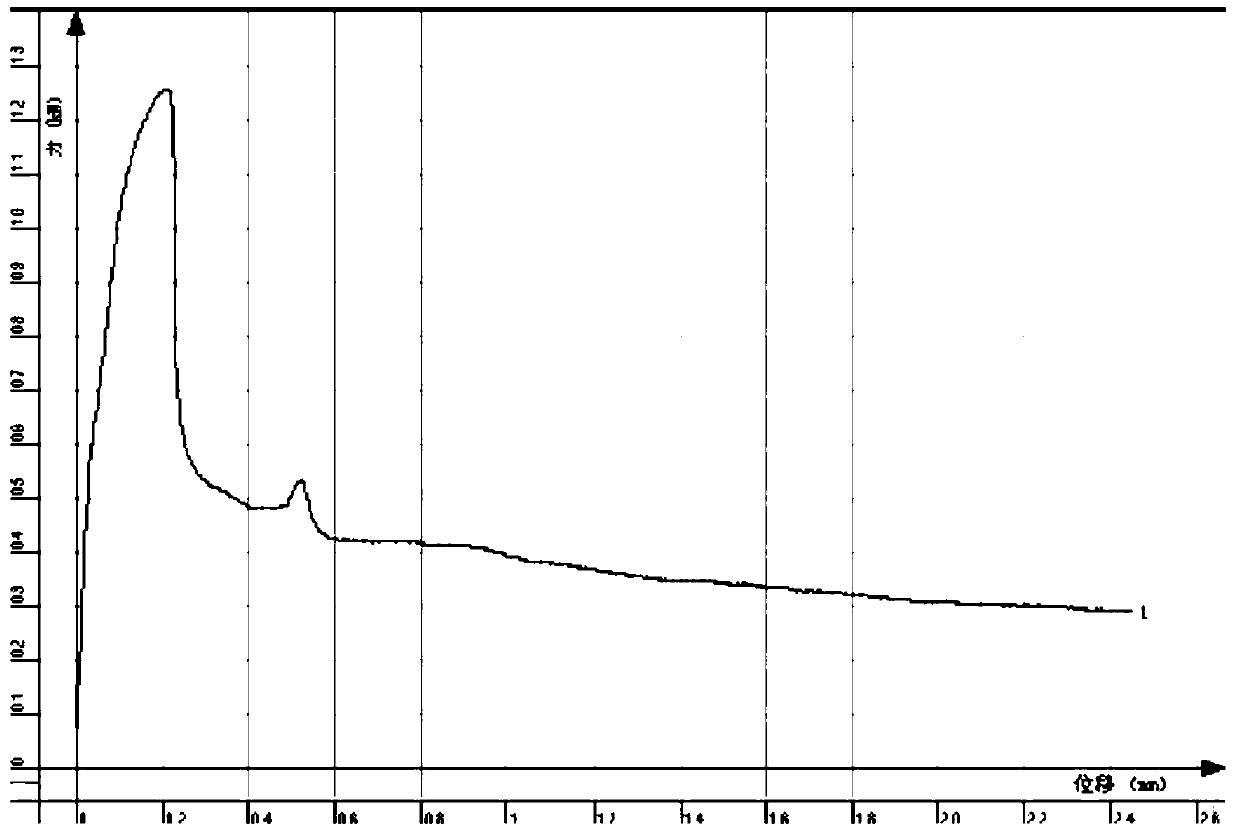

[0044] In step five, the pressure applied during cooling is 8KPa, and the cooling time is 20min. After the final test and analysis, such as image 3 , 4 As shown, the tensile strength of the adhesive layer reaches 1.01 MPa, and the good rate of the adhesive layer reaches 96.8%.

Embodiment 3

[0046]The difference from Example 1 is that the following parameters of the bonding process of a target for liquid crystal display, semiconductor, and electronics in this example are different

[0047] In Step 4, the injection rate is 30 m / min, and the injection temperature is 170°C.

[0048] In step five, the pressure applied during cooling is 7KPa, and the cooling time is 30min. After the final test and analysis, such as Figure 5 , 6 As shown, the tensile strength of the adhesive layer reaches 0.99MPa, and the good rate of the adhesive layer reaches 95.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com