Far-infrared functional master batch, far-infrared polyester fiber as well as preparation method and application

A technology of functional masterbatch and polyester fiber, which is applied in the field of far-infrared polyester fiber and its preparation, and far-infrared functional masterbatch, which can solve the problems of poor durability and water resistance, low far-infrared radiation, and poor matching of resonance bands. To achieve the effect of improving the efficacy of far infrared

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

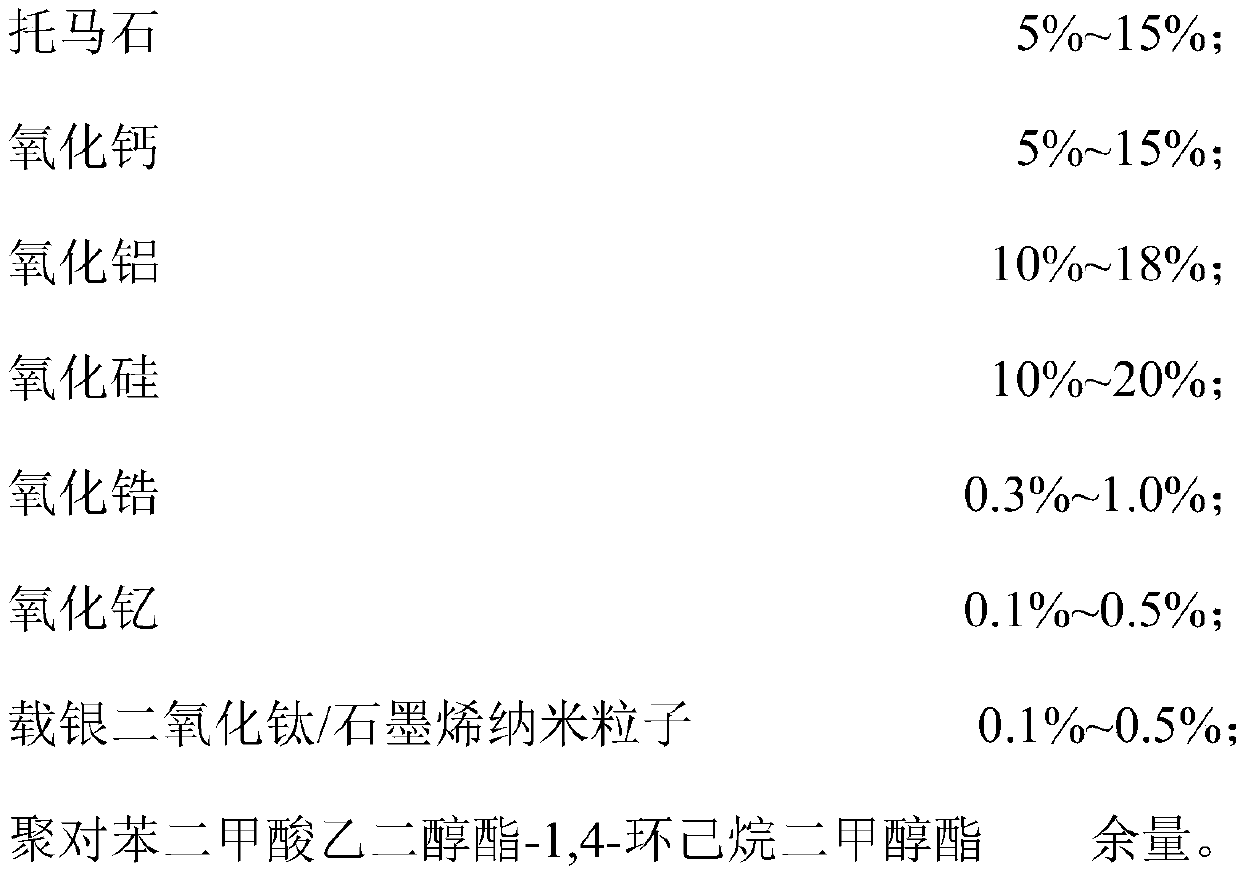

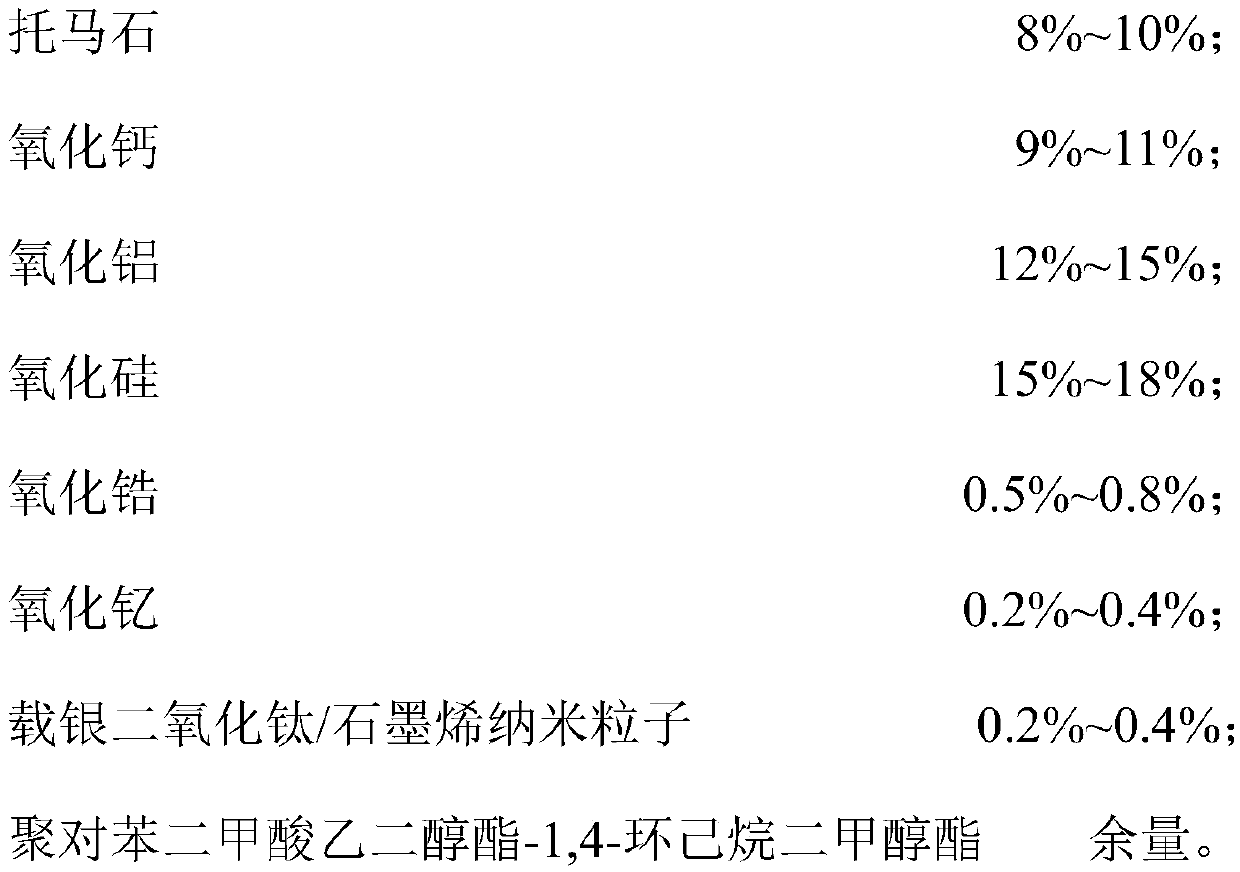

Method used

Image

Examples

preparation example Construction

[0047] The preparation method of the far-infrared polyester fiber of one embodiment, comprises the following steps S110~S120:

[0048] S110. Provide PET and far-infrared functional masterbatches.

[0049] Among them, the intrinsic viscosity of PET is 0.62-0.73.

[0050] Concrete, the preparation method of PET is as follows:

[0051] Dimethyl terephthalate and ethylene glycol with a molar ratio of 1:(2~2.3) are polycondensed at high temperature under the action of manganese acetate catalyst.

[0052] It can be understood that the above-mentioned PET can also be prepared by other existing methods or purchased directly, as long as the intrinsic viscosity is 0.62-0.73.

[0053] Specifically, the far-infrared functional masterbatch is prepared by the following steps S1101-S1105:

[0054] S1101. Provide silver-loaded titanium dioxide / graphene nanoparticles (Ag@TiO 2 / GO).

[0055] Wherein, the silver-loaded titanium dioxide / graphene nanoparticles are prepared by the following s...

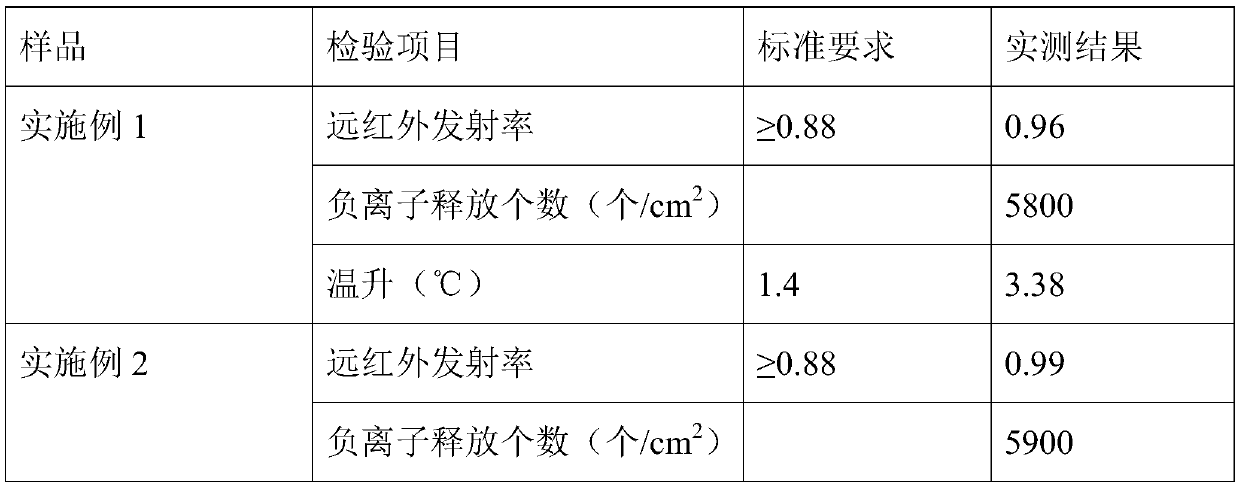

Embodiment 1

[0077] (1) Synthesis of PET fibers: Dimethyl terephthalate and ethylene glycol with a molar ratio of 1:2.2 are produced by high-temperature polycondensation under the action of catalyst manganese acetate, and the intrinsic viscosity is 0.68.

[0078] (2) Synthesis of PETG fiber: Dimethyl terephthalate, ethylene glycol and 1,4-cyclohexanedimethanol with a molar ratio of 1:1.8:0.3 are made by high-temperature polycondensation under the action of a catalyst. Viscosity number 0.65.

[0079] (3) Preparation of silver-loaded titanium dioxide / graphene (Ag@TiO2 / GO) particles: add an appropriate amount of polyvinylpyrrolidone (PVP-10) to a certain amount of ethylene glycol, stir to dissolve completely, and then add metered AgN03 , forming a clear and transparent solution, and while stirring, the solution was slowly heated to 120°C and kept for 1h. After the solution was cooled, it was extracted with acetone and centrifuged (5000 rpm) to remove the supernatant. The residue was then ce...

Embodiment 2

[0084] Example 2 is basically the same as Example 1, except that the far-infrared functional masterbatch in step (6) in Example 2 is 3 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com