A sleeve kiln gas intelligent control device and control method

An intelligent control, sleeve kiln technology, applied in furnace control device, combustion method, controlled combustion, etc., can solve the problems of stable gas supply, increased operation errors, poor lime quality, and cost that affect lime calcination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

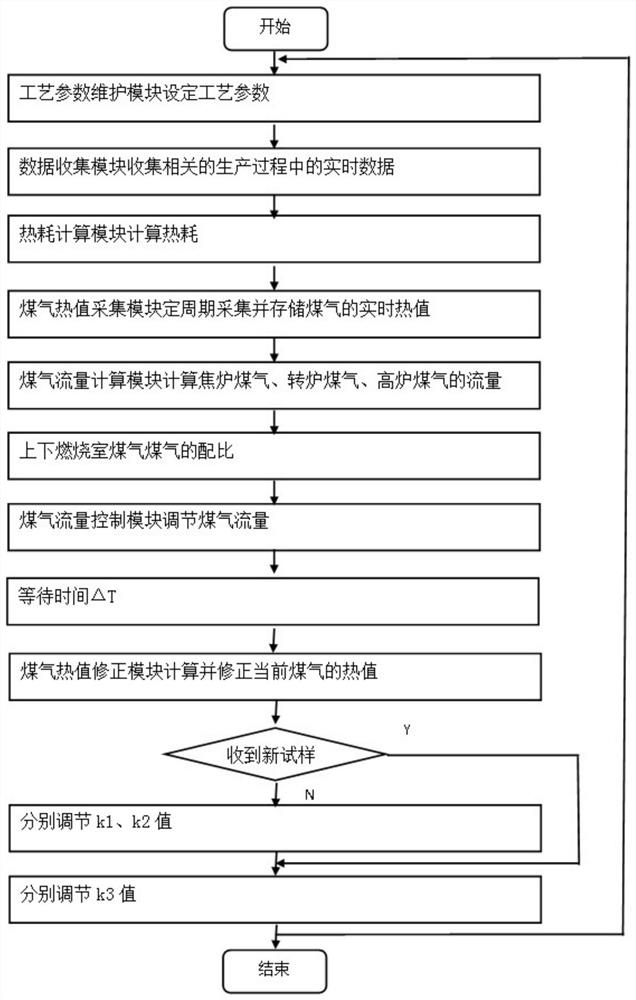

Embodiment 1

[0194] Take Meishan Steel's No. 1 sleeve kiln on June 25, 2017 as an example:

[0195] 1. The process parameter maintenance module sets the initial value of the process parameter or maintains the process parameter.

[0196] 2. The data collection module collects real-time data in the relevant production process;

[0197] 3. The heat consumption R of lime calcination is 970Kcal / Kg, the adjustment coefficient of reduction rate k1=1.02, the adjustment coefficient of activity k2=1.01, the heat coefficient of calcination k3=1.015, and the hourly lime output of 1# sleeve kiln is 19968.8Kg, then The heat consumption calculation module calculates the total heat consumption per unit time:

[0198] W=R*D*k1*k2*k3=970*19968.8*1.024*1.06*1.015=2.134×107Kcal / h

[0199] 4. The coal gas calorific value acquisition module regularly collects and stores the real-time calorific values of various gases and stores them in the database in the background of the system;

[0200] The cycle of gas...

Embodiment 2

[0225] Take the No. 3 sleeve kiln of Meishan Iron and Steel Co., Ltd. on June 30, 2017 as an example:

[0226] 1. The process parameter maintenance module sets the initial value of the process parameter or maintains the process parameter.

[0227] 2. The data collection module collects real-time data in the relevant production process;

[0228] 3. The heat consumption R of lime calcination is 975Kcal / Kg, the adjustment coefficient of reduction rate k1=1.02, the adjustment coefficient of activity k2=1.02, the heat coefficient of calcination k3=0.86, the hourly lime output of 1# sleeve kiln is 17750Kg, then the heat The consumption calculation module calculates the total calorie consumption per unit time:

[0229] W=R*D*k1*k2*k3=975*17750*1.02*1.02*0.86=1.5485×10 7 Kcal / h

[0230] 4. The coal gas calorific value acquisition module regularly collects and stores the real-time calorific values of various gases and stores them in the database in the background of the system;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com